Determination method for components of SF6 gas equipment fault melts

A technology for equipment failure and component determination, which is applied in the direction of measuring devices, material separation, and material analysis, can solve problems such as neglect of faulty melts, low content of faulty melts, and difficulties in quantitative analysis of components of SF6 gas equipment faulty melts, etc. Achieving an effect that is helpful for daily maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] In this example, the fault melt of SF6 gas equipment is taken from a substation GIS interval switch gas chamber

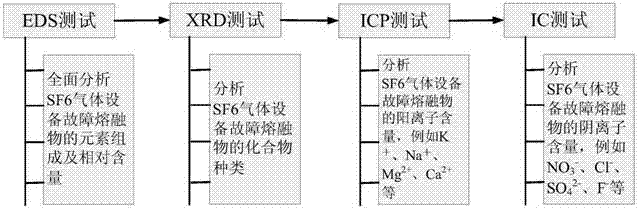

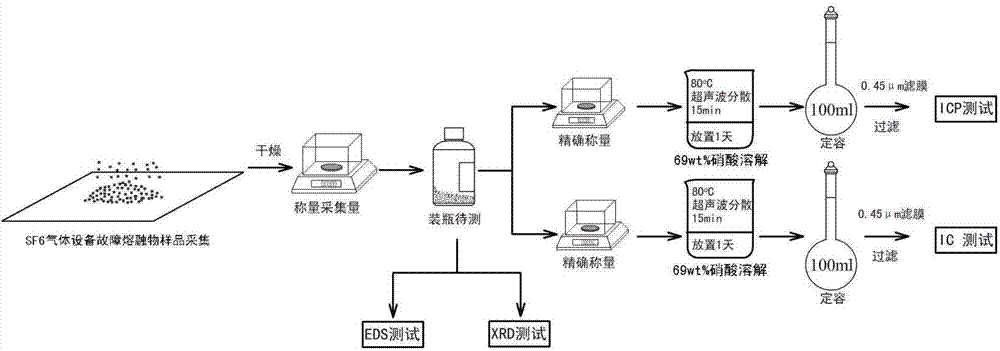

[0039] A kind of SF6 gas equipment failure melt composition determination method, the specific steps are as follows (please refer to figure 1 ):

[0040] A. Sample pretreatment:

[0041] Take the SF6 gas equipment failure melt sample and dry it in an oven to obtain sample 1;

[0042] B. Qualitative and semi-quantitative analysis:

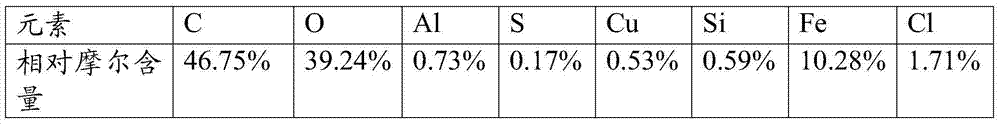

[0043] B1. Use EDS energy spectrometer to conduct element analysis test on sample 1 to determine the type and relative content of elements in sample 1. The process parameters of the element analysis test are: electron beam diameter: 5-10cm; tungsten wire electron gun thermal electron current intensity : 20keV; 1 ~ 30kV high voltage acceleration; cold finger position ≥ 40mm; distance ≥ 16mm; emission angle ≥ 35°, the results are as follows:

[0044]

[0045] B2, utilize X-ray diffraction spectrometer to test sample 1, determin...

Embodiment 2

[0055] In this example, the fault melt of SF6 gas equipment is taken from the GIS interval switch gas chamber of a certain substation.

[0056] A kind of SF6 gas equipment failure melt composition determination method, concrete steps are as follows:

[0057] A. Sample pretreatment:

[0058] Take the SF6 gas equipment failure melt sample and dry it in an oven to obtain sample 1;

[0059] B. Qualitative and semi-quantitative analysis:

[0060] B1. Use EDS energy spectrometer to conduct element analysis test on sample 1 to determine the type and relative content of elements in sample 1. The process parameters of the element analysis test are: electron beam diameter: 5-10cm; tungsten wire electron gun thermal electron current intensity : 20keV; 1 ~ 30kV high voltage acceleration; cold finger position ≥ 40mm; distance ≥ 16mm; emission angle ≥ 35°, the results are as follows:

[0061]

[0062] B2, utilize X-ray diffraction spectrometer to test sample 1, determine the compound ...

Embodiment 3

[0072] In this example, the fault melt of SF6 gas equipment is taken from a substation GIS interval switch gas chamber

[0073] A kind of SF6 gas equipment failure melt composition determination method, the specific steps are as follows (please refer to figure 2 ):

[0074] A. Sample pretreatment:

[0075] Take the SF6 gas equipment failure melt sample and dry it in an oven to obtain sample 1;

[0076] B. Qualitative and semi-quantitative analysis:

[0077] B1. Use EDS energy spectrometer to conduct element analysis test on sample 1 to determine the type and relative content of elements in sample 1. The process parameters of the element analysis test are: electron beam diameter: 5-10cm; tungsten wire electron gun thermal electron current intensity : 20keV; 1 ~ 30kV high voltage acceleration; cold finger position ≥ 40mm; distance ≥ 16mm; emission angle ≥ 35°, the results are as follows:

[0078]

[0079] B2, utilize X-ray diffraction spectrometer to test sample 1, deter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Launch angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com