Field programmable intelligent control system based on single-chip microcomputer

A technology of intelligent control system and single-chip microcomputer, which is applied in the field of control system, can solve the problems of product reliability decline, expensive PLC, complex function instructions, fieldbus function and online communication, etc., and achieve the effect of reducing the manufacturing cost of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

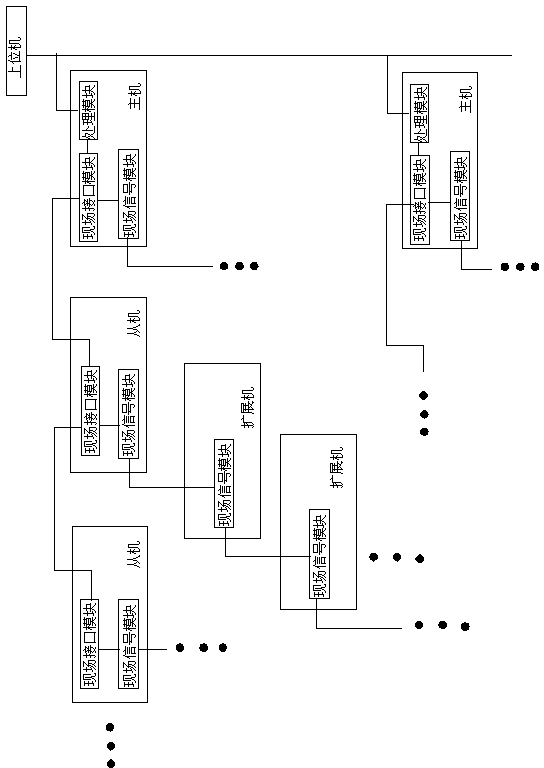

[0021] like figure 1 As shown in the figure, a field programmable intelligent control system based on single-chip microcomputer according to the present invention is composed of one or more groups of sub-control systems; the sub-control systems include a host, a slave and an expansion machine connected by a bus; The control system can include multiple slave machines and multiple expansion machines.

[0022] The host is used to process the field signals collected by the expansion machine, and send control signals to the field equipment through the expansion machine; the host is composed of a processing module, a field interface module and a field signal module connected through the bus. The processing module communicates with the processing module in the host computer in the host computer or other sub-control systems; the processing module also communicates with the field signal module, slave and expansion machine in the host computer through the field interface module.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com