Liquid phase epitaxy preparation method of multilayer embedded structure GaSb quantum dot materials

A quantum dot material and multi-layer structure technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of high toxicity and high cost, and achieve low production cost, wide application prospects, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

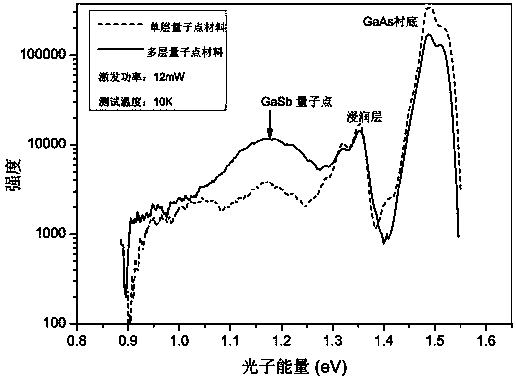

Examples

Embodiment 1

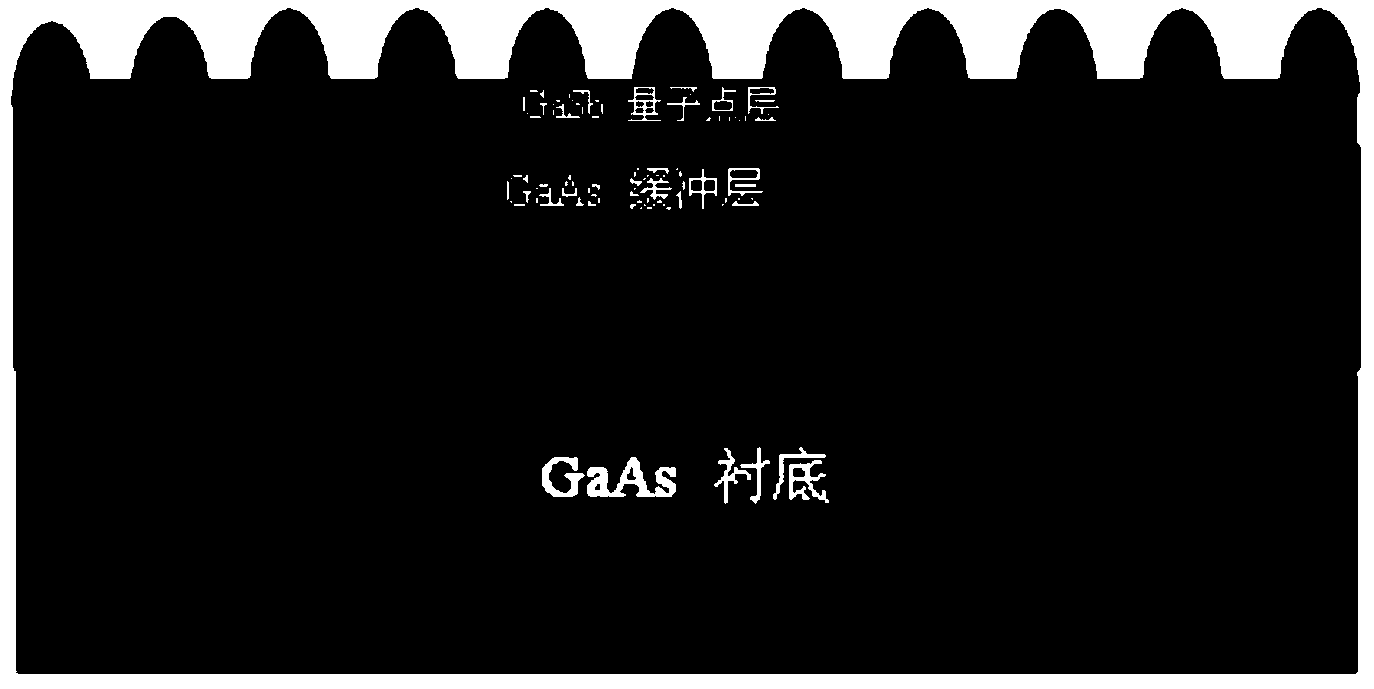

[0035] 1. Configuration of growth source

[0036] (1) Composition determination: the growth temperature of the GaAs buffer layer in this embodiment is 585°C, and the mass percentage of Ga / GaAs is 490.5; the growth temperature of the GaSb quantum dot layer is 585°C, and the mass percentage of Ga / Sb is 5.5 ; The growth temperature of the GaAs capping layer is 566°C, and the mass percentage of Ga / GaAs is 780.5. According to the size of the graphite liquid tank and the mass percentage of the above growth sources, the required amount of antimony (Sb), gallium (Ga) and gallium arsenide (GaAs) can be obtained.

[0037] (2) Weighing of growth source: According to the above calculation, use a microbalance to accurately weigh antimony (Sb), gallium (Ga) and gallium arsenide (GaAs) required for growth. The antimony (Sb) source and gallium (Ga) source used are both 99.99999% (7N) high-purity elemental sources, and gallium arsenide (GaAs) is a single crystal material.

[0038] 2. Prepara...

Embodiment 2

[0048] 1. Configuration of growth source

[0049] (1) Component calculation: the growth temperature of the GaAs buffer layer in the present invention is 580°C, and the mass percentage of Ga / GaAs is 534.61; the growth temperature of the GaSb quantum dot layer is 580°C, and the mass percentage of Ga / Sb is 5.8; The growth temperature of GaAs capping layer is 580℃, and the mass percentage of Ga / GaAs is 534.61. According to the size of the graphite liquid tank and the mass percentage of the above growth sources, the required amount of antimony (Sb), gallium (Ga) and gallium arsenide (GaAs) can be obtained.

[0050] (2) Weighing of growth source: According to the above calculation, use a microbalance to accurately weigh antimony (Sb), gallium (Ga) and gallium arsenide (GaAs) required for growth. The antimony (Sb) source and gallium (Ga) source used are both 99.99999% (7N) high-purity elemental sources, and gallium arsenide (GaAs) is a single crystal material.

[0051] 2. Preparato...

Embodiment 3

[0061] 1. Configuration of growth source

[0062] (1) Component calculation: the growth temperature of the GaAs buffer layer in the present invention is 572°C, and the mass percentage of Ga / GaAs is 560.71; the growth temperature of the GaSb quantum dot layer is 572°C, and the mass percentage of Ga / Sb is 7.1; The growth temperature of GaAs capping layer is 530℃, and the mass percentage of Ga / GaAs is 1376.23. According to the size of the graphite liquid tank and the mass percentage of the above growth sources, the required amount of antimony (Sb), gallium (Ga) and gallium arsenide (GaAs) can be obtained.

[0063] (2) Weighing of growth source: According to the above calculation, use a microbalance to accurately weigh antimony (Sb), gallium (Ga) and gallium arsenide (GaAs) required for growth. The antimony (Sb) source and gallium (Ga) source used are both 99.99999% (7N) high-purity elemental sources, and gallium arsenide (GaAs) is a single crystal material.

[0064] 2. Preparat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Growth temperature | aaaaa | aaaaa |

| Growth temperature | aaaaa | aaaaa |

| Growth temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com