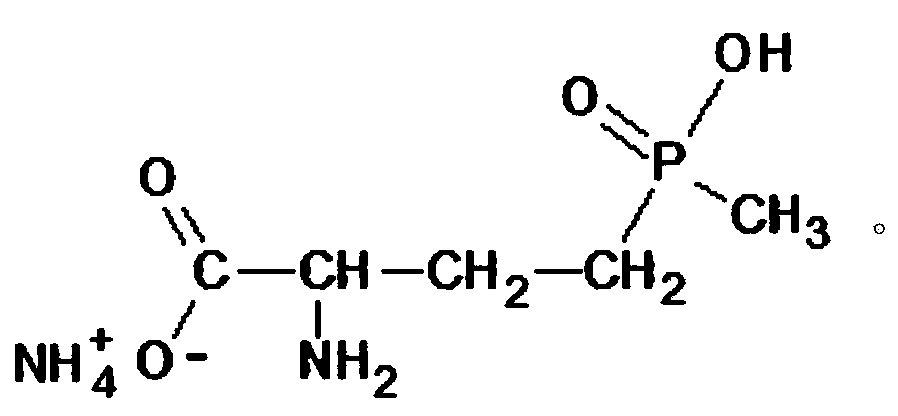

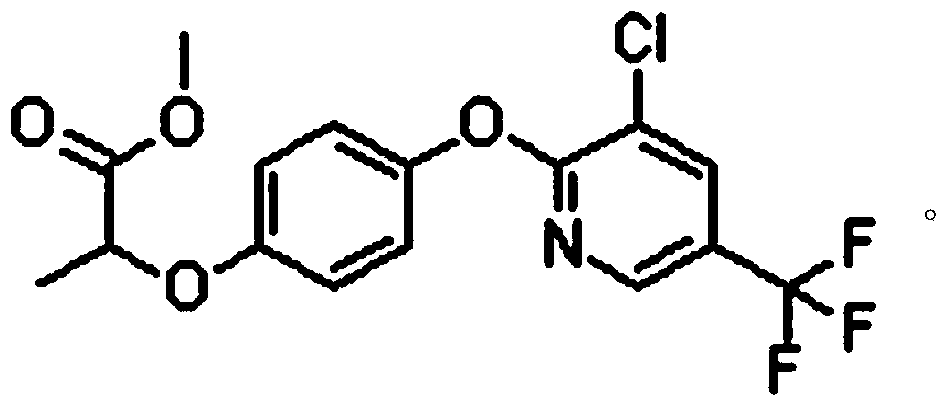

Weeding composition with glufosinate and efficient haloxyfop-methyl, and preparation method of weeding composition

A technology of high-efficiency haloxyfop-pyl and herbicidal composition, which is applied in the agricultural field, can solve the problems of incomplete control of older weeds, high cost of single use, and reduced herbicidal effect, so as to facilitate the display of drug efficacy and facilitate production Handling, easy-to-measure effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

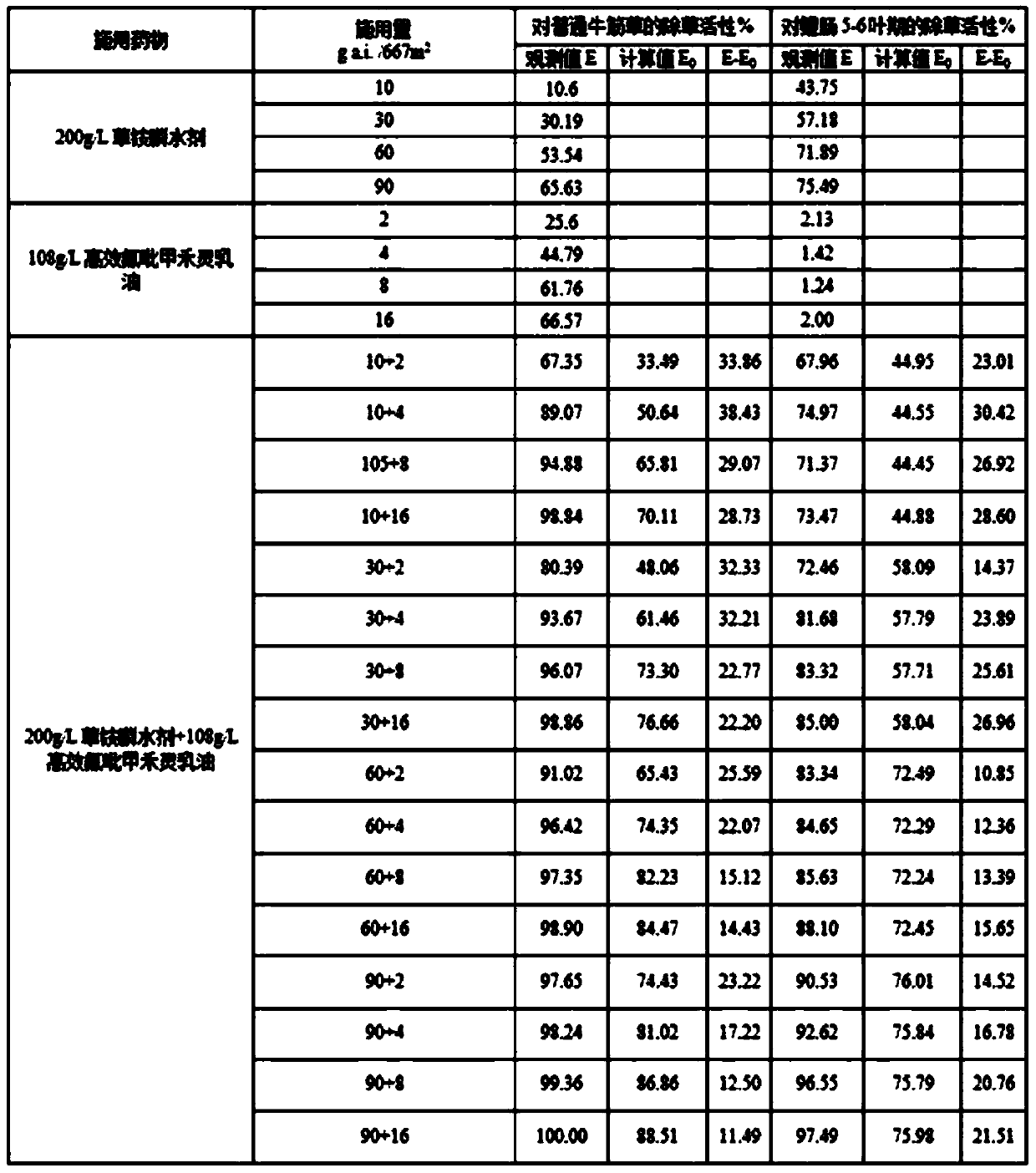

Examples

Embodiment 1

[0028] Preparation of 26% glufosinate · beta-haloxyfop (1:1.6) microemulsion

[0029] In this example, the mass ratio of glufosinate and haloxyfop-methyl is 1:1.6.

[0030] The following components were weighed according to the proportion: 10kg glufosinate, 16kg high-efficiency haloxyfop, 10.0kg cyclohexanone (solvent), 10.0kg propylene glycol methyl ether (solvent), 12.0kg fatty alcohol polyoxyethylene ether (No. One surfactant), 5.0kg ethylene glycol (antifreeze), 14.0kg ammonium dodecylbenzenesulfonate (second surfactant), 23kg water.

[0031] Glufosinate-ammonium was dissolved in water to obtain an aqueous phase mixture. Mix the remaining components and stir evenly to obtain an oil phase mixture. Mix the water phase mixture and the oil phase mixture, and stir evenly to obtain the product, which is a homogeneous transparent liquid.

Embodiment 2

[0033] Preparation of 23% glufosinate · beta-haloxyfop (45:1) microemulsion

[0034] In the present embodiment, the mass ratio of glufosinate and haloxyfop-methyl is 45:1.

[0035] Weigh the following components according to the proportion: 22.5kg glufosinate, 0.5kg high-efficiency flurifop-pyl, 3.0kg cyclohexanone (solvent), 5.0kg isopropanol (co-solvent), 10.0kg fatty alcohol polyoxyethylene ether (first surfactant), 5.0kg ethylene glycol (antifreeze), 10.0kg ammonium dodecylbenzenesulfonate (second surfactant), 44kg water.

[0036] Glufosinate-ammonium was dissolved in water to obtain an aqueous phase mixture. Mix the remaining components and stir evenly to obtain an oil phase mixture. Mix the water phase mixture and the oil phase mixture, and stir evenly to obtain the product, which is a homogeneous transparent liquid.

Embodiment 3

[0038] Preparation of 12% glufosinate · beta-haloxyfop (1:3) microemulsion

[0039] In this embodiment, the mass ratio of glufosinate and haloxyfop-methyl is 1:3.

[0040]Weigh the following components according to the ratio: 3kg glufosinate, 9kg high-efficiency haloxyfop, 15.0kg C9 (solvent, C9 is trimethylbenzene), 8.0kg propylene glycol methyl ether (solvent), 15.0kg nonylphenol polyoxyethylene Ether (first surfactant), 5.0kg propylene glycol (antifreeze), 16.0kg calcium dodecylbenzenesulfonate (second surfactant), 29kg water.

[0041] Glufosinate-ammonium was dissolved in water to obtain an aqueous phase mixture. Mix the remaining components and stir evenly to obtain an oil phase mixture. Mix the water phase mixture and the oil phase mixture, and stir evenly to obtain the product, which is a homogeneous transparent liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com