Activating method of inactive platinum/palladium catalyst

A deactivated catalyst and activation method technology, applied in the field of deactivated platinum/palladium catalyst activation, can solve the problems of lack of wide applicability, short regeneration time, etc., achieve good elution effect, simple equipment structure, and less dosage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

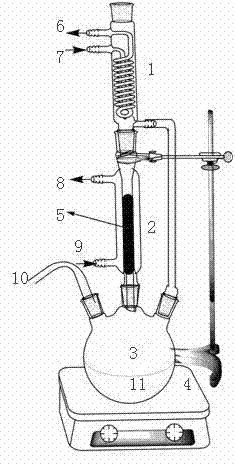

[0019] Embodiment 1: Small batch deactivation platinum / palladium catalyst activation equipment

[0020] Small batch deactivated platinum / palladium catalyst activation equipment such as figure 1 As shown, the three-necked flask 3 is used as the evaporation chamber, the jacketed pipe is used as the rinse chamber for the rinse pipe 2, and the condensation pipe 1 is used as the condensation chamber. Before activation, the deactivated catalyst is placed in the jacketed tube, the detergent is added into the three-necked flask, and the equipment is assembled according to the diagram. When activating, turn on the condensing pipe to cool the water, and the jacket pipe to control the water temperature. After the temperature is stable, turn on the carrier gas and heat the three-necked bottle to the predetermined temperature at the same time. Adjust the flow rate of the carrier gas so that the liquid level of the detergent in the jacket is higher than that of the catalyst and remains st...

Embodiment 2

[0021] Example 2: Activation of deactivated platinum-carbon catalyst

[0022] use figure 1 Reaction device, wherein the reaction chamber is a 250mL glass three-necked flask, and the three-necked flask is placed in a water bath. 100g of an inactivated platinum-carbon (5%) catalyst from a certain pharmaceutical factory is placed in a jacketed tube, and 150mL of dichloromethane is added to the three-necked flask. Adjust the cooling liquid temperature in the condenser tube to -5°C, heat the three-necked flask to 60°C, turn on the nitrogen carrier gas, and adjust the gas velocity to keep the solvent in the jacketed tube about 3cm higher than the catalyst. After washing for 12 hours, open the connection between the condenser tube and the washing tube, close the interface of the washing tube, connect the condenser tube with a 250mL single-mouth bottle, and maintain the operating parameters for 0.5 hours to recover the detergent. Take the washed catalyst out and soak it in 10% hydroc...

Embodiment 3

[0023] Example 3: Activation of deactivated platinum-alumina catalyst

[0024] use figure 1 Similar to the activation device, the reaction chamber is a 500mL glass three-necked flask, and the three-necked flask is placed in a heating jacket. 200g of a deactivated platinum-alumina catalyst from a fine chemical plant is placed in a jacketed tube, and 150mL of cyclohexane is added to the three-necked flask. Turn on the nitrogen carrier gas, adjust the cooling water temperature of the condenser tube to 0°C, and stabilize the heating mantle to 90°C o C, adjust the nitrogen flow rate to keep the solvent in the jacketed tube about 3cm higher than the catalyst. After washing for 6 hours, open the condenser tube to connect it with the washing tube, close the interface of the washing tube, connect it under the condenser tube with a 250mL single-necked flask, and maintain the operation for 0.5 hours to recover the detergent. Take out the washed catalyst and soak it in 10% hydrochloric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com