Visible-light catalyst of C60 implanted into mesoporous CdS/TiO2 duct and preparation method of catalyst

A catalyst, visible light technology, used in physical/chemical process catalysts, chemical instruments and methods, hydrogen production, etc., to achieve the effect of promoting the photocatalytic process, avoiding recombination, and excellent conduction of electrons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

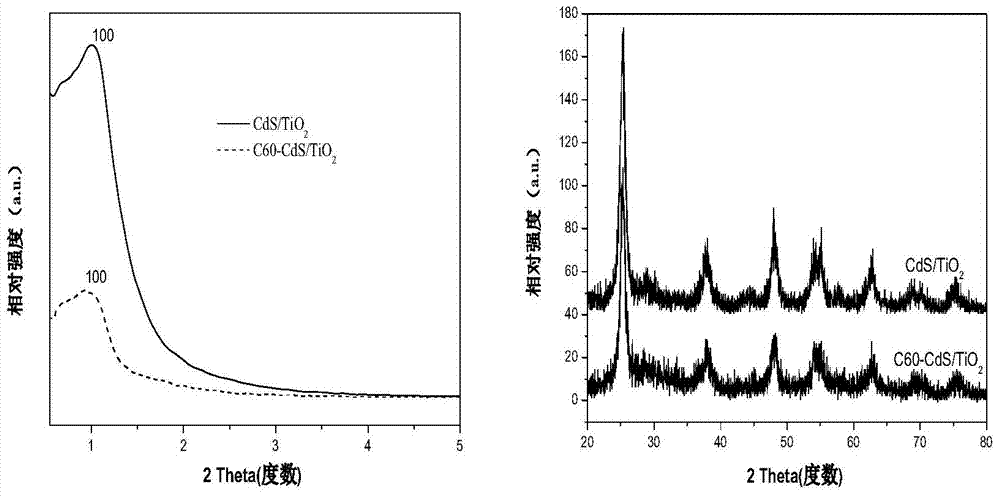

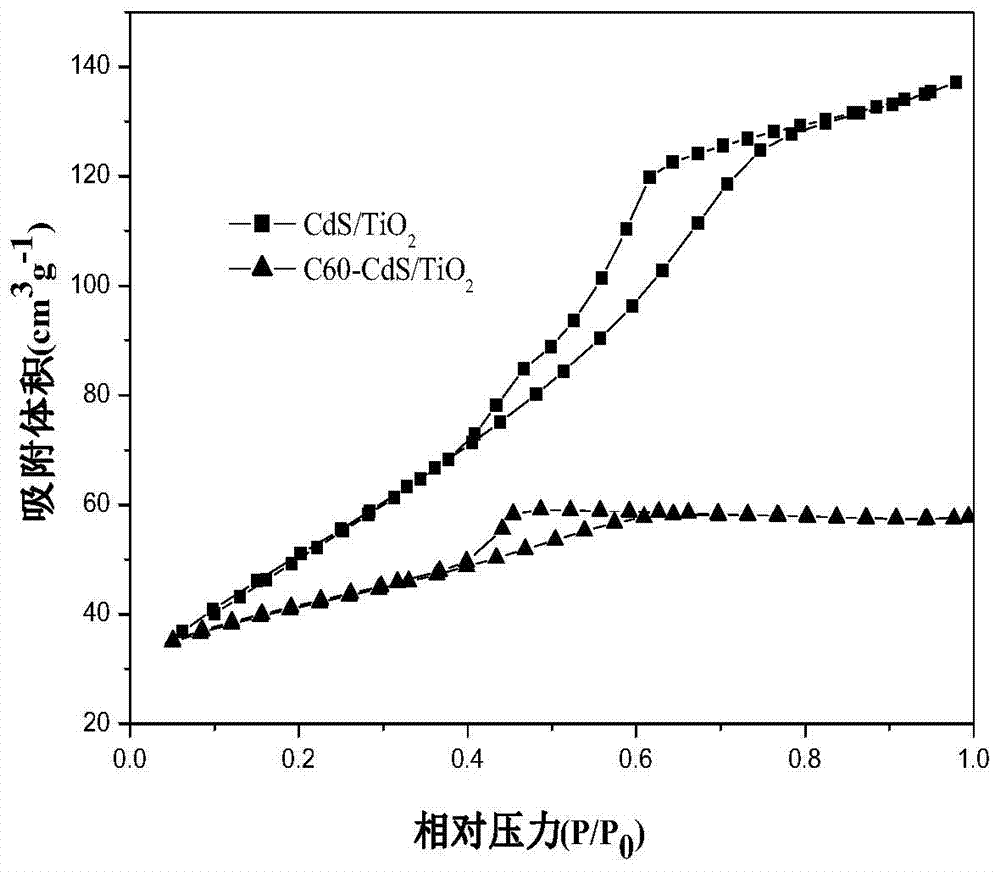

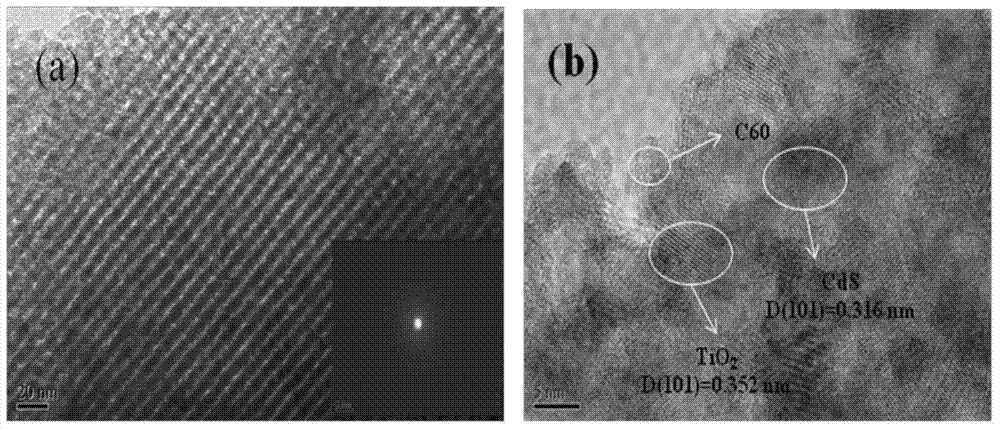

[0030] At room temperature, take 1.5g of F127 and add it to 19ml of ethanol solution, stir evenly to fully dissolve, then add 0.21g of Cd(NO 3 ) 2 4H 2 O and 1.5ml prepared C60 toluene solution (200mg C60 dissolved in 100ml toluene), stir well; then add 0.015mol titanium tetrachloride solution dropwise to the solution, continue stirring for 0.5h (C60:TiO 2 =0.25wt.%); the solution was transferred to a petri dish and dried at 40°C for four days; then the baked dish was fired at 400°C to obtain CdO with ordered mesoporous structure modified by C60 quantum dots / TiO 2 ; Get 0.3g roasted sample and add to 50ml0.2mol / L Na 2 S solution, stirred at room temperature for 6h, centrifuged, washed and dried to obtain the C60 quantum dot modified CdS / TiO we need 2 catalyst of light. The sample is named 0.25wt.%C60-CdS / TiO 2 .

Embodiment 2

[0032] At room temperature, take 1.5g of F127 and add it to 19ml of ethanol solution, stir evenly to fully dissolve, then add 0.21g of Cd(NO 3 ) 2 4H 2 O and 3.0ml prepared C60 toluene solution (200mg C60 dissolved in 100ml toluene), stir well; then add dropwise 0.015mol titanium tetrachloride solution to the solution, continue stirring for 0.5h (C60:TiO 2 =0.5wt.%); the solution was transferred to a petri dish and dried at 40°C for four days; then the baked dish was baked at 400°C to obtain CdO with ordered mesoporous structure modified by C60 quantum dots / TiO 2; Get 0.3g roasted sample and add to 50ml0.2mol / L Na 2 S solution, stirred at room temperature for 6h, centrifuged, washed and dried to obtain the C60 quantum dot modified CdS / TiO we need 2 catalyst of light. The sample is named 0.5wt.%C60-CdS / TiO 2 .

Embodiment 3

[0034] At room temperature, take 1.5g of F127 and add it to 19ml of ethanol solution, stir evenly to fully dissolve, then add 0.21g of Cd(NO 3 ) 2 4H 2 O and 6.0ml prepared C60 toluene solution (200mg C60 dissolved in 100ml toluene), stir evenly; then add 0.015mol titanium tetrachloride solution dropwise to the solution, continue stirring for 0.5h (C60:TiO 2 =1.0wt.%); the solution was transferred to a petri dish and dried at 40°C for four days; then the baked dish was baked at 400°C to obtain CdO with ordered mesoporous structure modified by C60 quantum dots / TiO 2 ; Get 0.3g roasted sample and add to 50ml0.2mol / L Na 2 S solution, stirred at room temperature for 6h, centrifuged, washed and dried to obtain the C60 quantum dot modified CdS / TiO we need 2 catalyst of light. The sample is named 1.0wt.%C60-CdS / TiO 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com