Manufacture method of chemicals independent cargo hold in hull

A manufacturing method and chemical technology, applied in shipbuilding, ship parts, ships, etc., can solve the problems of limited loading flexibility, easily damaged coating, and easily contaminated goods, so as to improve the competitiveness of the international market and manufacture The effect of short cycle time and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with embodiment the present invention is described in further detail.

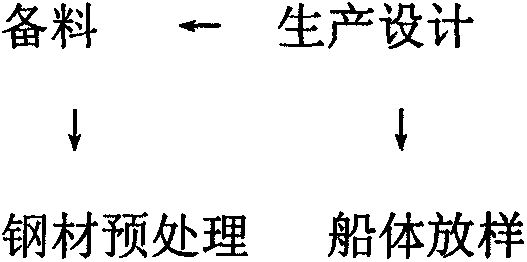

[0028] A method for manufacturing an independent cargo tank for chemicals in a ship hull, characterized in that it comprises the following steps:

[0029] 1. Design drawings, prepare materials, and process stainless steel parts to be processed by stainless steel manufacturers;

[0030] 2. Scribe and cut the stainless steel after pretreatment;

[0031] 3. Cold processing of stainless steel components;

[0032] 4. Assemble and weld the cold-worked stainless steel components;

[0033] 5. Segmented assembly and welding of stainless steel;

[0034] 6. Independent cabin assembly;

[0035] 7. Finally, after the pickling passivation tightness test, it is launched into the water.

[0036] The stainless steel is selected from duplex stainless steel composed of austenite and ferrite, or duplex stainless steel is used for the stainless steel with both sides contacting the liquid cargo ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com