A kind of lead-free low-melting point glass-ceramic powder and preparation method thereof

A technology of glass-ceramic powder and low melting point, which is applied in the field of inorganic materials, can solve problems such as limited sintering temperature range, and achieve the effects of wide sintering temperature range, high melting temperature and fine crystals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

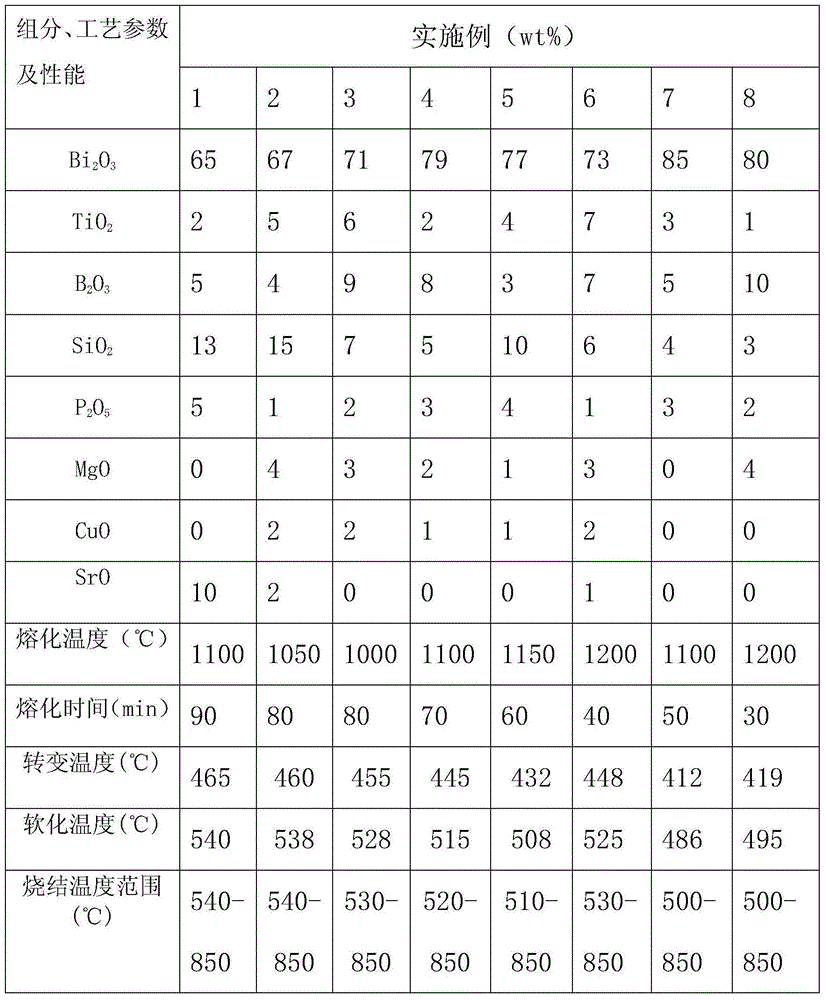

Examples

preparation example Construction

[0029] The preparation method of a kind of lead-free low melting point glass-ceramic powder of the present invention is:

[0030] Weigh each raw material according to weight percentage, fully mix each raw material to make a mixture, melt the obtained mixture at 1000°C-1200°C for 30min-90min to become molten glass, cool and solidify the melted glass, and make Glass flakes or glass blocks; pulverize the prepared glass flakes or glass blocks in a ball mill to prepare glass powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com