Graphite heat-conducting adhesive tape

A technology of graphite heat conduction and adhesive tape, which is applied in the direction of adhesives, adhesive types, ester copolymer adhesives, etc., can solve the problem of promotion of applications that are difficult to apply to specific use occasions, and the heat dissipation effect is not as good as imagined. Electronics The heat dissipation requirements of components are high, so as to achieve the effect of facilitating the diffusion of heat, avoiding the concentration of heat, and facilitating the dispersion and transmission of heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

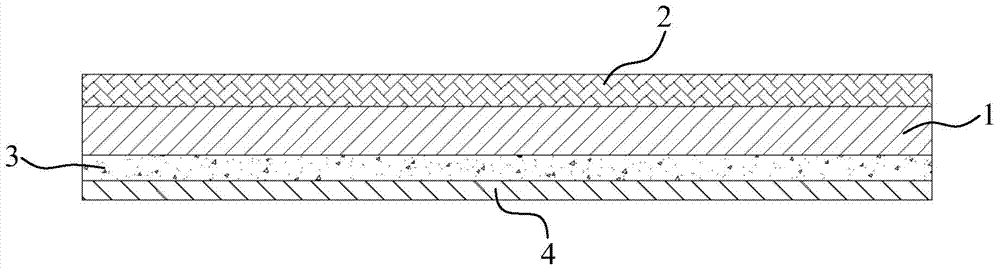

[0032] Embodiment: A graphite heat-conducting adhesive tape, comprising a PET film with a thickness of 0.004mm~0.025mm, an aluminum foil layer is coated on the upper surface of the PET film, a heat-conducting adhesive layer is coated on the lower surface of the PET film, and a release paper is pasted On the other surface of the thermally conductive adhesive layer, the thermally conductive adhesive layer is obtained by mixing and baking the following components in parts by weight:

[0034] graphite powder 130,

[0035] Solvent 200,

[0036] Curing agent 0.8,

[0037] Coupling agent 0.07;

[0038] Described acrylate adhesive is made up of following components by weight:

[0039] Butyl Acrylate 100,

[0040] Benzoyl peroxide 0.6,

[0041] Isooctyl Acrylate 90,

[0042] Acrylic 2,

[0043] Methyl methacrylate 12,

[0044] Vinyl acetate 3,

[0045] 2-hydroxyethyl methacrylate 0.5;

[0046] The thickness ratio of the PET film, the thermally...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com