A kind of gold alloy material with high fineness and high hardness and preparation method thereof

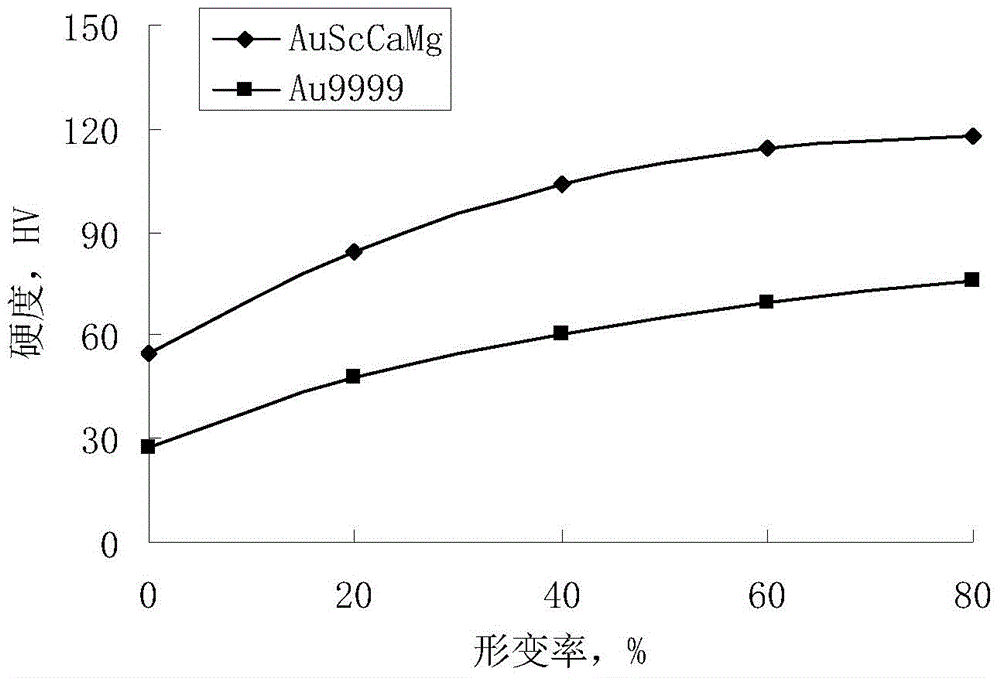

An alloy material and high hardness technology, applied in the field of high fineness and high hardness gold alloy material and its preparation, can solve the problems of natural aging softening, dullness, poor luster of modified pure gold, etc., and achieve the effect of fine grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

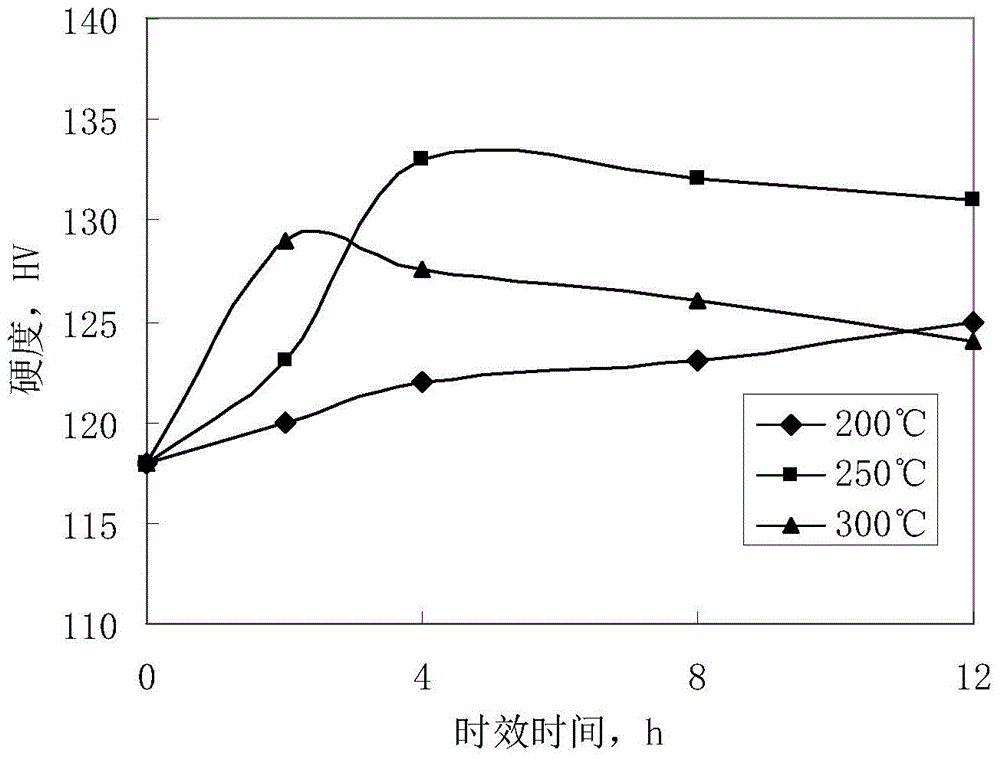

Examples

preparation example Construction

[0033] A method for preparing a high-color and high-hardness gold alloy material, comprising the following steps:

[0034] a. Preparation of gold-scandium master alloy: Au9999 pure gold and Sc9999 pure scandium are melted in a vacuum electric arc furnace according to the mass ratio of (89-91): 1 to prepare a gold-scandium master alloy;

[0035] b. Preparation of gold-calcium master alloy: according to the mass ratio (159-161): 1, Au9999 pure gold and Ca999 pure calcium are melted in a vacuum electric arc furnace to obtain a gold-calcium master alloy;

[0036] c. Preparation of gold-magnesium master alloy: according to the mass ratio (269-271): 1, Au9999 pure gold and Mg9999 pure magnesium are melted in a vacuum electric arc furnace to obtain a gold-magnesium master alloy;

[0037] d. Ingredients: the gold-scandium master alloy prepared in step a, the gold-calcium master alloy prepared in step b, the gold-magnesium master alloy prepared in step c, and Au9999 pure gold are cut i...

Embodiment 1

[0049] The preparation method of the high fineness and high hardness gold alloy of the present embodiment comprises the following steps:

[0050] a. Melt pure gold and pure scandium with a mass ratio of Au9999 pure gold: Sc9999 pure scandium = 90:1 in a vacuum electric arc furnace to obtain a gold-scandium master alloy.

[0051] b. Melting pure gold and pure calcium with a mass ratio of Au9999 pure gold: Ca999 pure calcium = 160:1 in a vacuum electric arc furnace to obtain a gold-calcium master alloy.

[0052] c. Melt pure gold and pure magnesium with a mass ratio of Au9999 pure gold: Mg9999 pure magnesium = 270:1 in a vacuum electric arc furnace to obtain a gold-magnesium master alloy.

[0053] d. According to the mass percentage of 27% gold-scandium master alloy, 18% gold-calcium master alloy, 13% gold-magnesium master alloy, and the rest are Au9999 pure gold ingredients, the raw materials are all in the form of small particles through cutting ( The particle size is 1-5mm)....

Embodiment 2

[0062] The preparation method of the high fineness and high hardness gold alloy of the present embodiment comprises the following steps:

[0063] a. Melt pure gold and pure scandium with a mass ratio of Au9999 pure gold: Sc9999 pure scandium = 90:1 in a vacuum electric arc furnace to obtain a gold-scandium master alloy.

[0064] b. Melting pure gold and pure calcium with a mass ratio of Au9999 pure gold: Ca999 pure calcium = 160:1 in a vacuum electric arc furnace to obtain a gold-calcium master alloy.

[0065] c. Melt pure gold and pure magnesium with a mass ratio of Au9999 pure gold: Mg9999 pure magnesium = 270:1 in a vacuum electric arc furnace to obtain a gold-magnesium master alloy.

[0066] d. According to the mass percentage, it is 37% gold-scandium master alloy, 25% gold-calcium master alloy, 26% gold-magnesium master alloy, and the rest are Au9999 pure gold ingredients, and the raw materials are all in the form of small particles through cutting ( The particle size is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com