Controllable vibration electrostatic spinning device

An electrospinning and controllable technology, applied in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve problems such as low production efficiency and uneven spinning fibers, so as to improve production efficiency and improve fiber quality. Quality, effect of improving liquidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

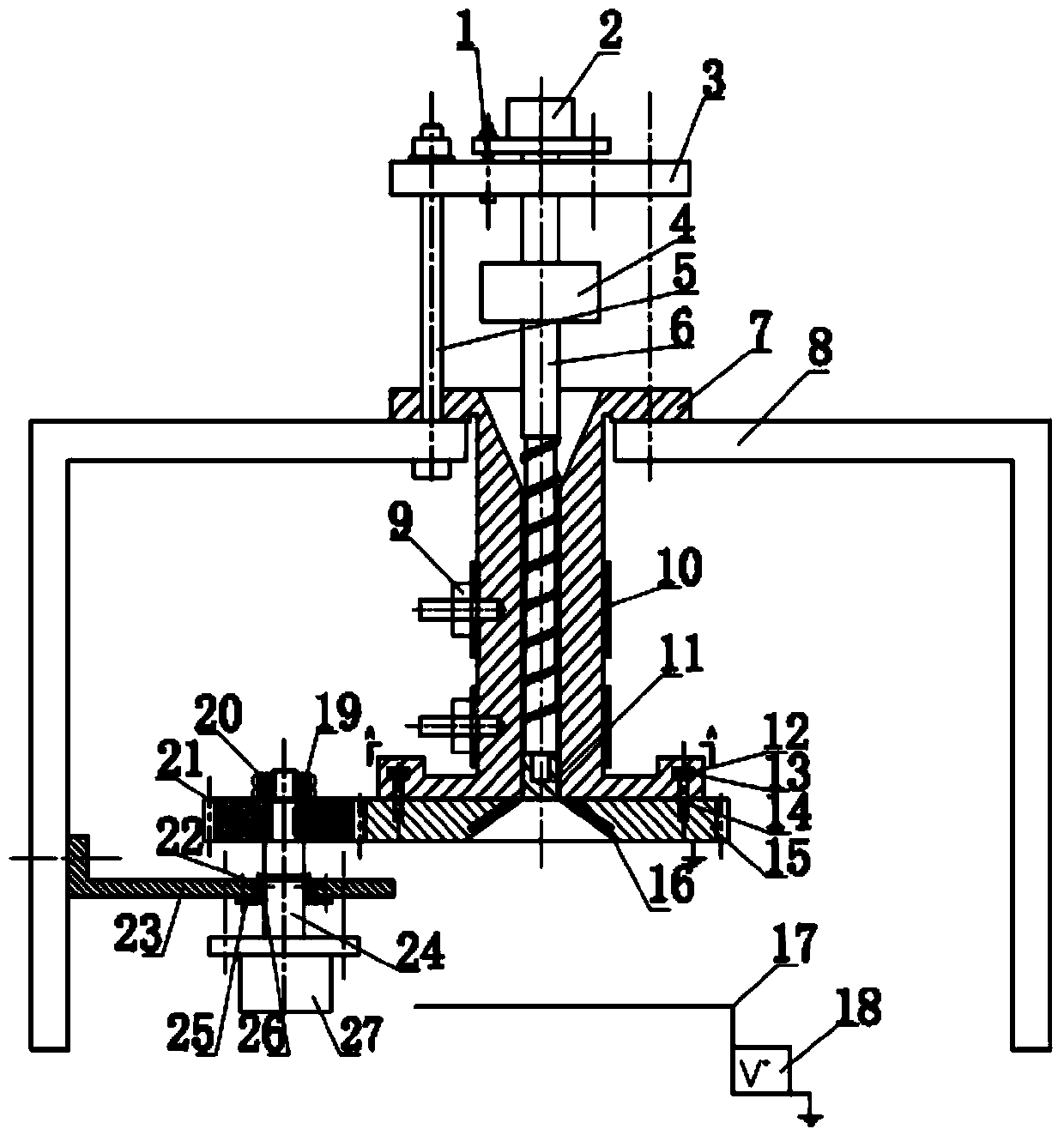

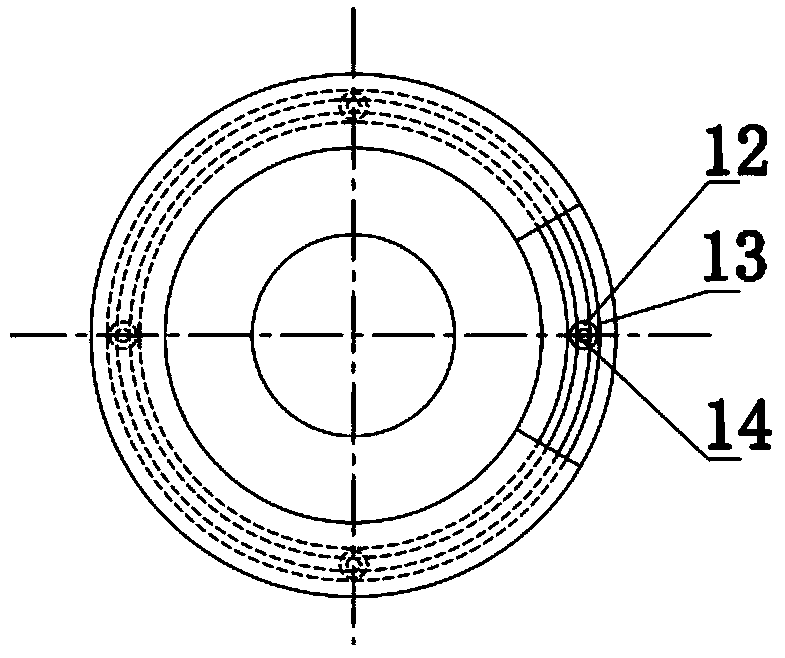

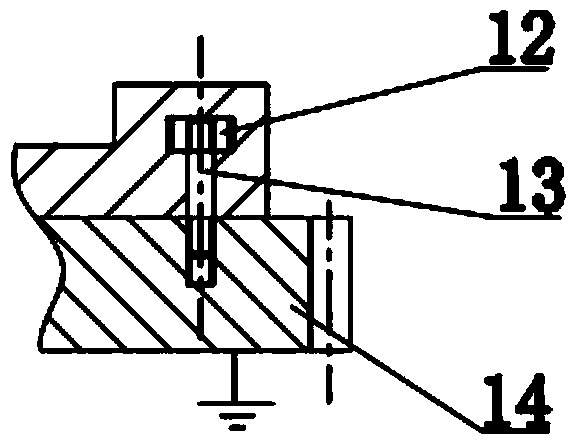

[0016] The present invention proposes a controllable vibration electrospinning device, such as figure 1 As shown, it includes a feeding motor 2, a coupling 4, a heating device 10, a temperature sensor 9, a barrel 7, a nozzle 15, a stepping motor 27, a meshing gear 21, a screw 6, a piezoelectric transducer 16, and a receiving device 17. High-voltage electrostatic generator 18 and support 8, the whole spinning device is fixed on the support 8.

[0017] The feeding motor 2 is fixed on the feeding motor fixing plate 3 by the charging motor connecting bolt 1, and is connected with the barrel 7 through the fixing plate bolt 5. First, the two heating devices 10 are respectively set at different temperature levels, heated to a preset temperature, the temperature sensor 9 detects the actual temperature, and the temperature control box adjusts the temperature. Then turn on the feeding motor 2, the feeding motor 2 drives the screw 6 through the coupling 4, and extrudes the polymer to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com