Mixed-flow type water pump turbine

A pump-turbine, mixed-flow technology, applied in the field of mixed-flow pump-turbine, can solve problems such as instability, de-flow, hydraulic loss, and large secondary flow loss, and achieve the possibility of reducing vibration, improving flow performance, and secondary flow. The effect of small flow loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

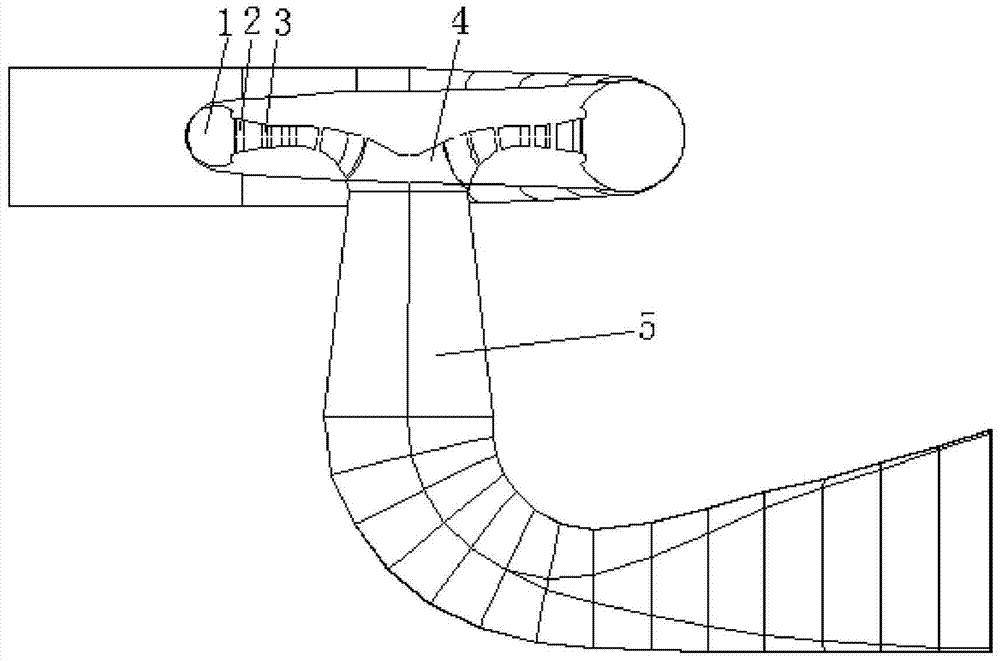

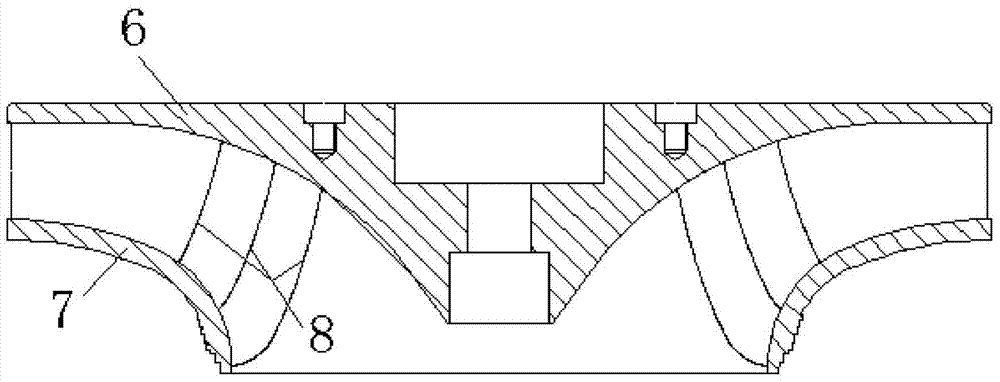

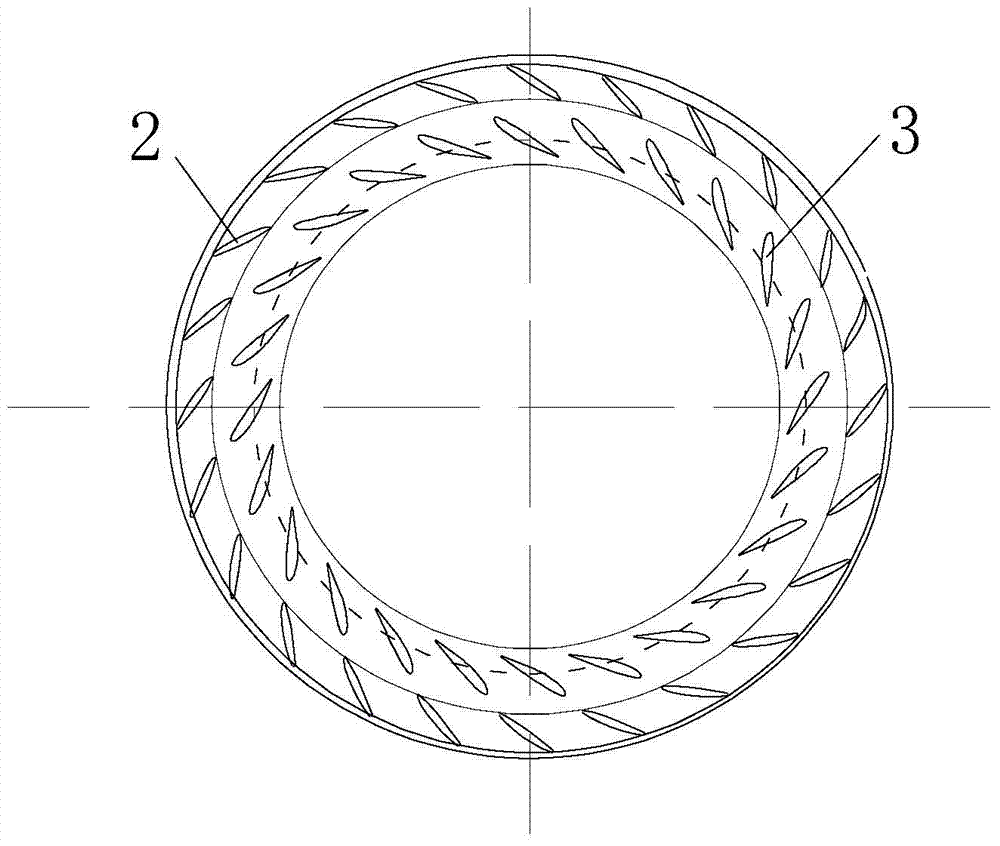

[0036] Such as Figure 1-8 As shown, it is a Francis water pump turbine of the present invention, including a volute 1, a fixed guide vane 2, a movable guide vane 3, a runner 4 and a draft tube 5, the runner 4 is located in the middle of the volute 1, and the fixed guide vane 2 and movable guide vanes 3 are distributed in the volute 1 close to the runner 4, the draft tube 5 is connected to the middle of the bottom surface of the volute 1, the runner 5 is mainly composed of the upper crown 6, the lower ring 7 and the blade 8, and the blade 8 is located on the upper crown Between 6 and the lower ring 7, the blades 8 are distributed in groups along the circumference of the lower ring 7. In this embodiment, there are 5 groups of blades, and each group of blades consists of a long blade 9, a medium-long blade 10 and two short blades 11. , one of the short blades is located between the long blades 9 and the middle and long blades 10 as the first short blade 12 , and the other short ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com