Device for automatically detecting remainders in aerospace engine

An automatic detection device and aerospace engine technology, which is applied in the direction of analyzing materials and instruments, can solve the problems of unstable operation, mechanical impact interference, and low detection efficiency, so as to reduce labor intensity, avoid interference signals, and achieve stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

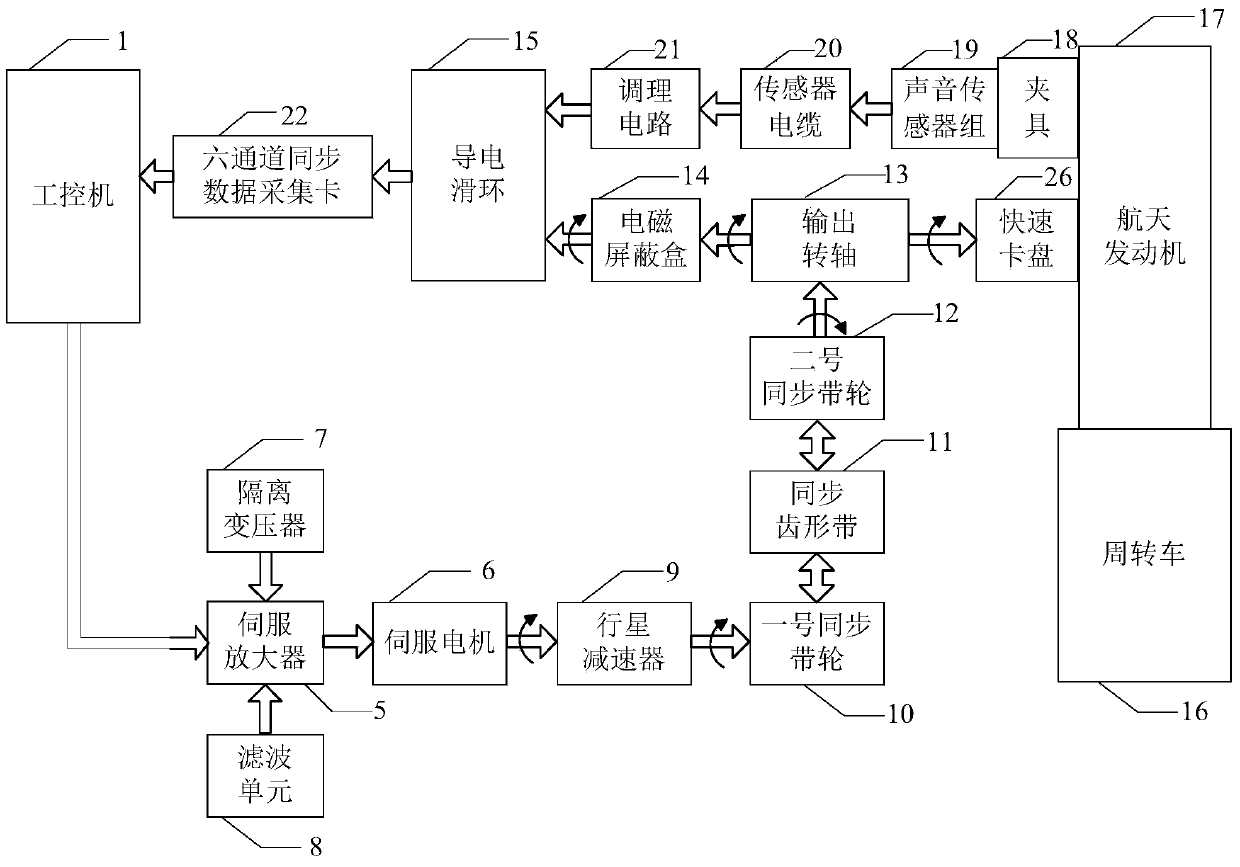

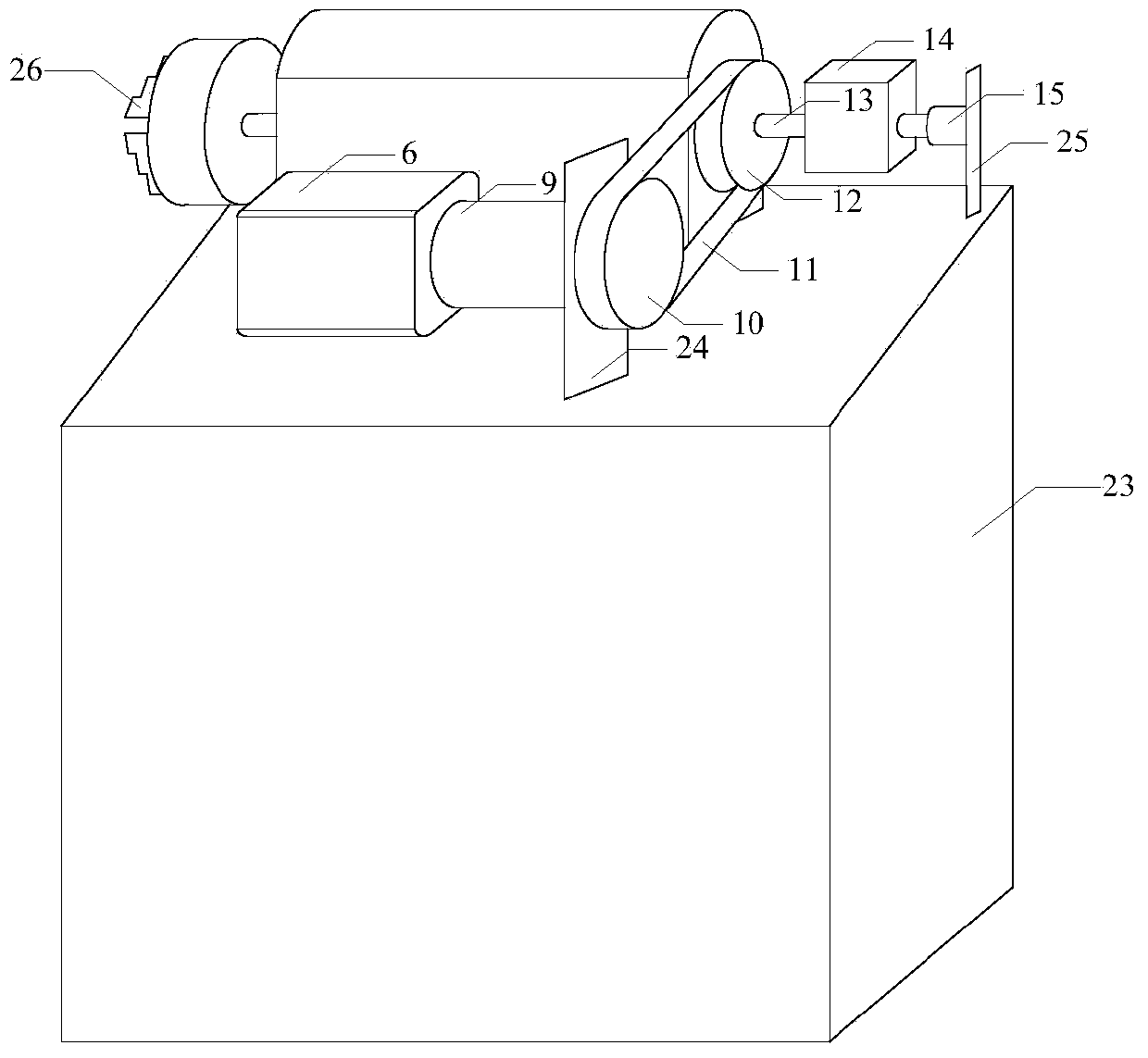

[0027] Specific implementation mode one: the following combination figure 1 , image 3 and Figure 10 Describe this embodiment, a kind of aerospace engine excess automatic detection device described in this embodiment, it comprises industrial computer 1, servo amplifier 5, servo motor 6, planetary reducer 9, No. 1 synchronous pulley 10, synchronous toothed belt 11. No. 2 synchronous pulley 12, output shaft 13, electromagnetic shielding box 14, conductive slip ring 15, turnover car 16, fixture 18, sound sensor group 19, sensor cable 20, conditioning circuit 21, six-channel synchronous data acquisition card 22 and quick chuck 26;

[0028] The control signal output terminal of the industrial computer 1 is connected with the input terminal of the servo amplifier 5;

[0029] The output end of the servo amplifier 5 is connected with the drive end of the servo motor 6;

[0030] The output shaft of the servo motor 6 is connected to the input shaft of the planetary reducer 9, and t...

specific Embodiment approach 2

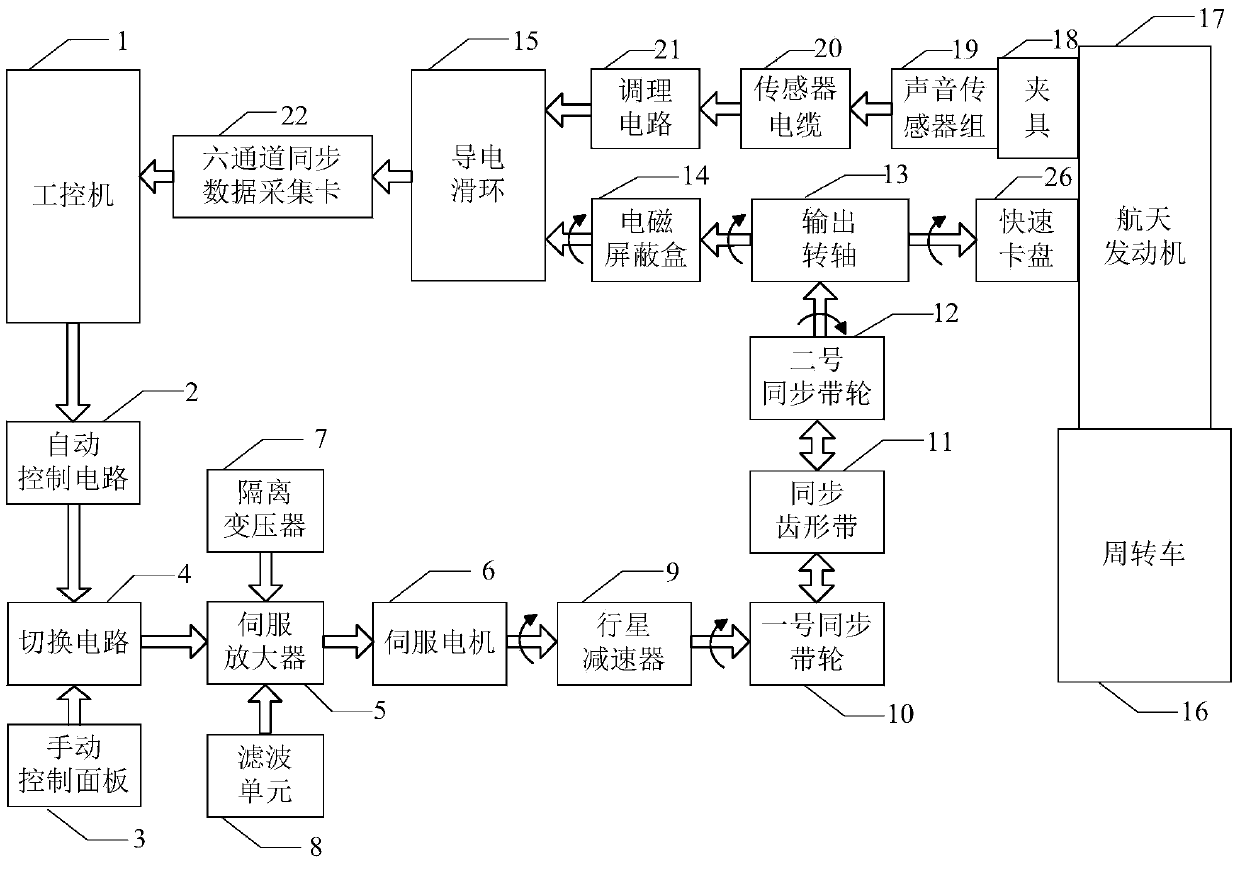

[0041] Specific implementation mode two: the following combination figure 2 and image 3 Describe this embodiment mode, this embodiment mode will further explain embodiment one, it also includes automatic control circuit 2, manual control panel 3 and switching circuit 4;

[0042] The control signal output end of the industrial computer 1 is connected with the input end of the automatic control circuit 2;

[0043] The output end of the automatic control circuit 2 is connected with the automatic control signal input end of the switching circuit 4;

[0044] The output terminal of the manual control panel 3 is connected with the manual control signal input terminal of the switching circuit 4;

[0045] The output terminal of the switching circuit 4 is connected with the input terminal of the servo amplifier 5 .

[0046]The servo system has two control modes: manual control and automatic control. When the servo system works in the automatic control mode, the industrial computer ...

specific Embodiment approach 3

[0052] Embodiment 3: This embodiment further describes Embodiment 1 or 2. It also includes an isolation transformer 7 , and the isolation transformer 7 is arranged between the output end of the power supply line and the input end of the servo amplifier 5 .

[0053] Isolation transformer 7: When the servo amplifier 5 and the servo motor 6 are working, a large amount of high-frequency electromagnetic interference will be generated. Since the servo system and the detection system are at the same grid point, the high-frequency interference of the servo system may flow back to the power supply and ground wire of the grid, causing interference to the detection equipment. The 380V power supply line is used to supply power to the servo system separately after passing through the three-phase isolation transformer, so that the servo system and the detection system do not have electrical contact, thereby effectively isolating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com