Method for preparing and extracting theabrownin by using tea leaves as raw material

A technology for theabrownin and tea leaves, applied in the field of preparation and extraction of theabrownin, can solve the problems of high energy consumption cost, less theabrownin, complex components, etc., and achieves overcoming the variety of organic solvents, reducing the production cost, and improving the recovery rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

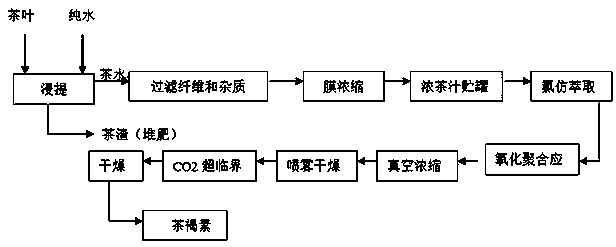

Method used

Image

Examples

Embodiment 1

[0023] A method for preparing and extracting theabrownin from tea leaves, comprising the following steps:

[0024] (1) Take 20g of ordinary green tea (or other tea varieties), grind it into flakes, put it into a beaker, pour 200ml of 90-100% pure water into it, and heat it to maintain a constant temperature for 60 minutes, then extract the liquid, and repeat the extraction once under the same conditions;

[0025] (2) heating and concentrating the above-mentioned 400ml extract to 150ml;

[0026] (3) Add 150ml of concentrated solution from the previous step to 150ml of chloroform solution for extraction, leaving 150ml of the lower aqueous layer;

[0027] (4) inject 150ml of the water layer in the previous step into the airtight melting vessel and carry out the oxidative polymerization reaction for 60min;

[0028] (5) After the oxidative polymerization reaction is completed, distill and dry to obtain 5.35 g of fine theabrownin in a solid state of more than 80%.

Embodiment 2

[0030] A method for preparing and extracting theabrownin from tea leaves, comprising the following steps:

[0031] (1) Take 20g of ordinary green tea (or other tea varieties), grind it into flakes, put it into a beaker, pour 100ml of 70-80% pure water into it, and keep it at a constant temperature for 40 minutes with heating, then extract the liquid, and repeat the extraction once under the same conditions;

[0032] (2) Heat and concentrate the above-mentioned 200ml extract to 150ml;

[0033] (3) Add 150ml of the concentrate from the previous step to 150ml of chloroform solution for extraction, leaving 150ml of the lower aqueous layer;

[0034] (4) Inject 150ml of the water layer in the previous step into a closed melting vessel for oxidative polymerization for 30min;

[0035] (5) After the oxidative polymerization reaction is completed, distill and dry to obtain 4.45 g of solid theabrownin fine product with a theabrownin content of more than 80%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com