Automatic filtering device for low-temperature coal tar and working method of automatic filtering device

A low-temperature coal tar, automatic filtration technology, used in tar processing, filtration and separation, petroleum industry and other directions, can solve the problems of large solid particle content, sewage oil, inability to achieve continuous operation, increase the difficulty of post-processing, etc., and achieve service life. Long, reduce labor cost, shorten the effect of filtration cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with accompanying drawing.

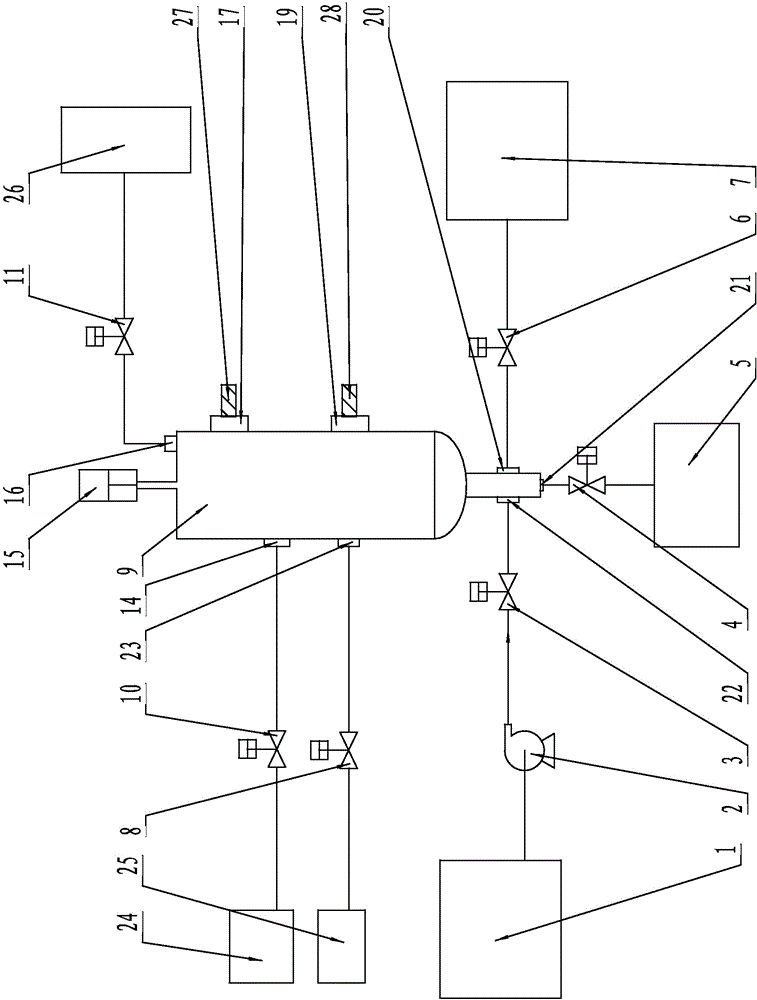

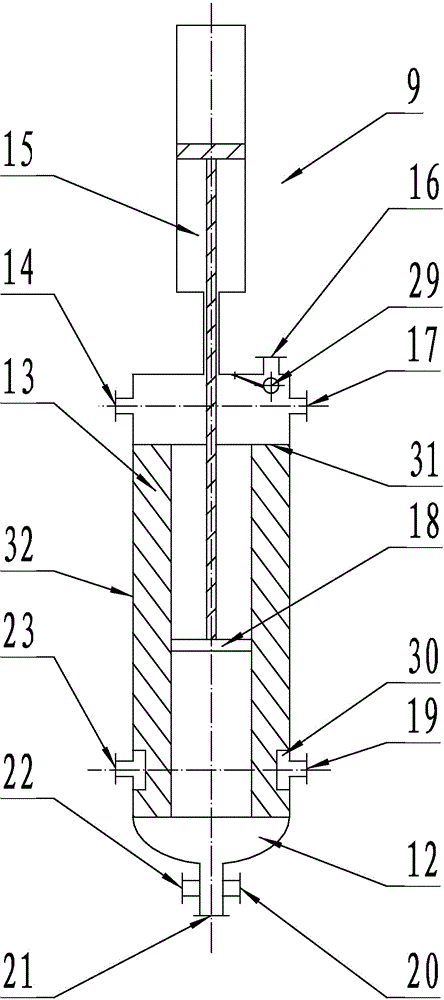

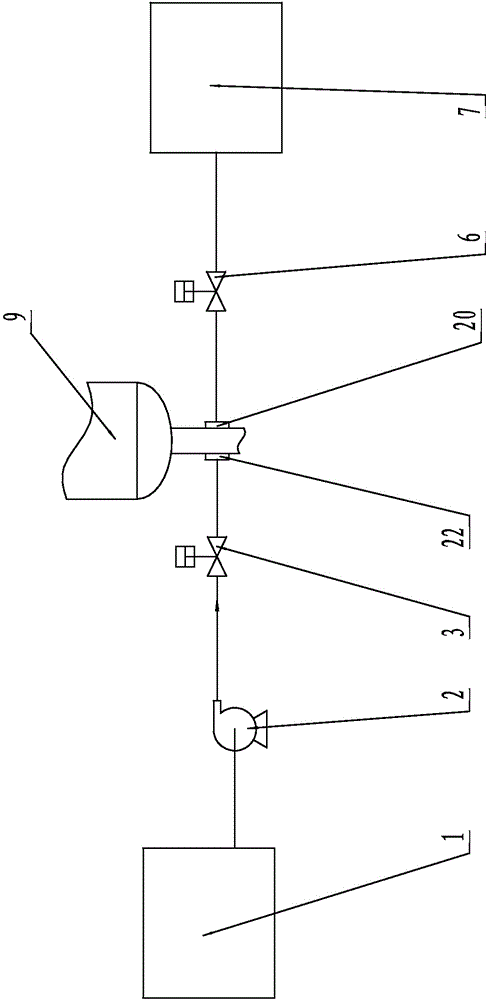

[0043] Such as Figure 1-9 As shown, an automatic filter device for low-temperature coal tar mainly includes a filter 9, a filter system, a cleaning system, a slag discharge system, and a control system;

[0044] The filter 9 includes a filter tank 12, a wedge wire wound filter element 13, a raw liquid inlet 14, a cylinder 15, an exhaust port 16, an upper pressure measuring port 17, a slag scraping piston 18, a lower pressure measuring port 19, a cleaning liquid Outlet 20, slag discharge port 21, cleaning liquid inlet 22, clear liquid outlet 23, ball float valve 29; described filter tank body 12 and wedge wire winding filter element 13, stock solution inlet 14, cylinder 15, exhaust port 16, The upper pressure measuring port 17, the lower pressure measuring port 19, the cleaning liquid outlet 20, the slag discharge port 21, the cleaning liquid inlet 22, the clear liquid out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com