Mechanical vapor recompression heat pump mvr sludge drying system

A technology of sludge drying and mechanical steam, applied in the direction of dewatering/drying/concentrating sludge treatment, etc., can solve the problems of high investment cost and complicated additional equipment, achieve stable system operation, save primary energy, and eliminate steam superheat. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

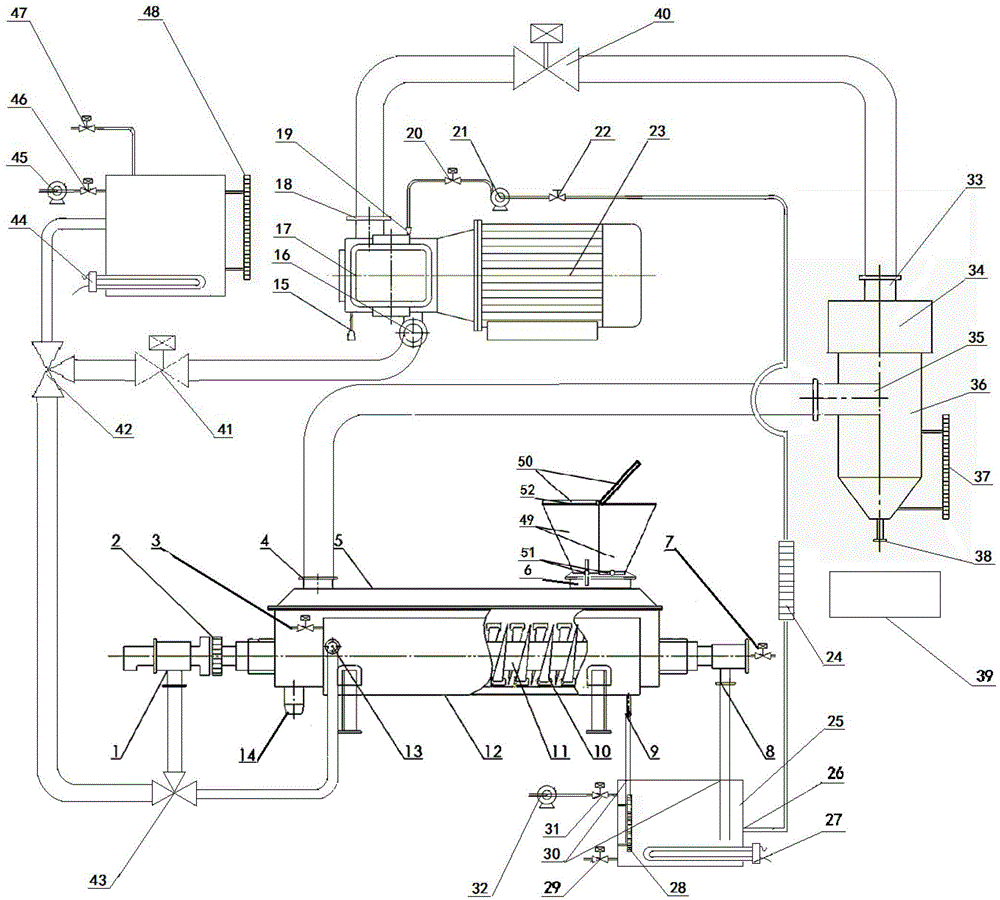

[0054] Such as figure 1 The sludge drying system using MVR technology shown mainly includes a water vapor compressor system, a hollow paddle dryer, and a secondary steam separator, steam compensation water tank and condensation Water tank 25.

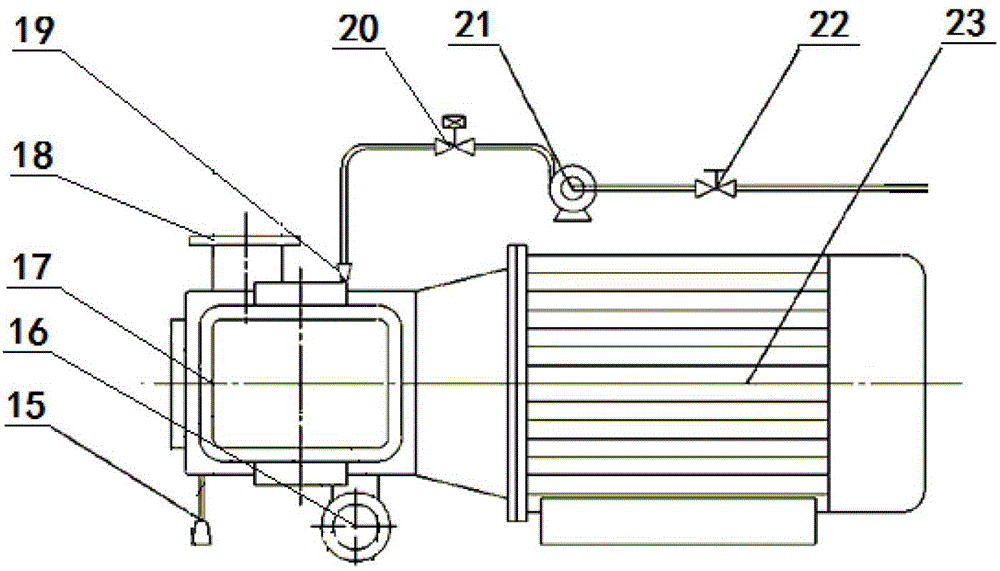

[0055] Such as figure 2 Shown, described water vapor compressor system mainly is made up of water vapor compressor, but preferred single-screw water vapor compressor 17 also includes shock absorber 15, driving motor 23 and compressor cooling water system; The upper part of the body of machine 17 is provided with secondary steam inlet 18 and is provided with recompression steam outlet 16 at the bottom of the compressor body, and rubber shock absorber 15 is also arranged at the bottom of the body; Further reduce mechanical vibration during operation. The single-screw water vapor compres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com