Production method of super-transparent soft PVC (polyvinyl chloride) film

A PVC film, transparent and soft technology, applied in the production field of ultra-transparent and soft PVC film, can solve the problems of not being able to control the degree of plasticization well, not being able to reuse and recycle, and the color of the product turning yellow, so as to save materials, Smooth heating and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

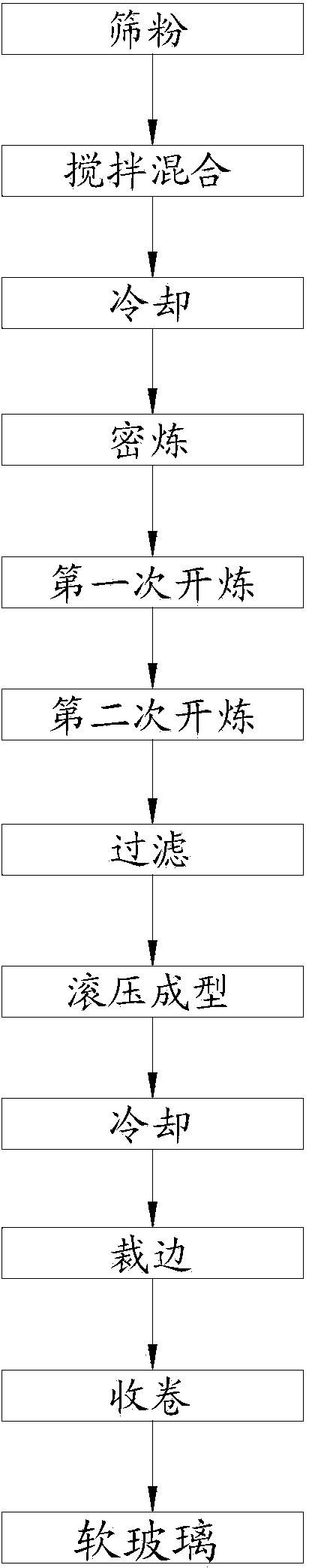

[0029] Such as figure 1 Shown, the production method of a kind of ultra-transparent flexible PVC film described in the present embodiment, comprises the steps:

[0030] 1) Powder sieving: put the PVC resin powder into a sieving machine for sieving, initially remove impurities, and obtain powder A; in step 1), cotton gauze gloves cannot be used, and at the same time, the sieve needs to be cleaned regularly; because once Cotton yarn falls into the raw material, which is difficult to remove in subsequent steps, resulting in residues on the product and becoming a defective product; in this step, impurities are initially removed through sieving to obtain a relatively pure powder A, which is then sent to the powder storage tank.

[0031] 2) Stirring and mixing: Put the powder A obtained in step 1) into the mixer together with the plasticizer, stabilizer, lubricant, and pigment for stirring to obtain the mixed powder B; wherein, the stirring speed is 696 rpm, and the stirring time is...

Embodiment 2

[0044] A kind of production method of ultra-transparent flexible PVC film is characterized in that comprising the steps:

[0045]1) Powder sieving: put the PVC resin powder into a sieving machine for sieving, initially remove impurities, and obtain powder A;

[0046] 2) Stirring and mixing: discharge powder A together with plasticizer, stabilizer, lubricant, and pigment into the mixer for stirring to obtain mixed powder B; wherein, the stirring speed is 696 rpm, and the stirring time is 230 seconds. The temperature is 150°C;

[0047] 3) Cooling: Cooling by stirring at a low speed, the stirring speed is 348 rpm, the stirring time is 40 seconds, and the temperature is controlled below 90°C to obtain a dry mixed powder C (white powder);

[0048] 4) Internal mixing: discharge the mixed powder C into the internal mixer, pressurize the internal mixer for internal mixing, the internal mixer is equipped with two rollers, and use the shear pressure between the rollers to process the m...

Embodiment 3

[0055] The characteristics of this embodiment are: in step 4), after adding the mixed powder C, at the same time add the recycled side material (the side material cut in the previous production process) and pressurize banburying, and the weight of the recovered side material is the mixed powder 10%-15% of the weight of body C, too much will affect the degree of plasticization of the product, which can save materials, reduce costs, and improve plasticization efficiency. Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com