Aluminum-plastic composite panel with high rigidity and high bending strength and preparation method of aluminum-plastic composite panel

A bending strength, aluminum-plastic composite technology, applied in the field of aluminum-plastic composite panels, can solve the problems of aluminum-plastic composite panel strength, time-consuming and labor-intensive, aluminum-plastic composite panel shelling, etc., to achieve convenient manufacturing, cost reduction, and environmental friendliness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

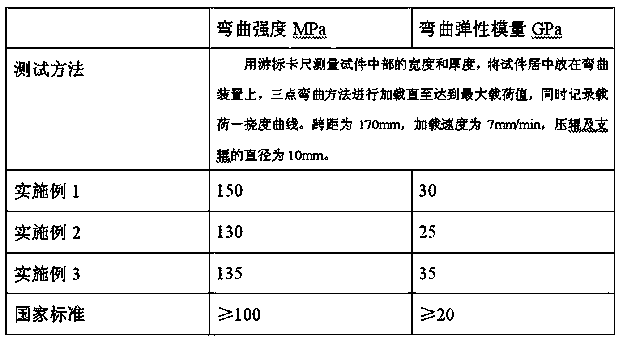

Examples

example 1

[0036] PE 80Kg

[0037] PP 28Kg

[0038] Modified Nano Calcium Carbonate 8Kg

[0039] Dicumyl peroxide 0.5Kg

[0040] Triallyl isocyanurate 1Kg

[0041] Tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythritol ester 0.15Kg

[0042] (1) Mix the silane coupling agent with the solution (water / ethanol volume ratio is 1:5);

[0043] (2) Mix calcium carbonate with 6% by mass silane coupling agent solution evenly, and dry in vacuum for 15 hours at 80°C to obtain modified nano-calcium carbonate;

[0044] (3) Weigh the required mass according to the formula;

[0045] (4), PE / PP, dicumyl peroxide, triallyl isocyanurate, [β-tetrakis (3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid] The pentaerythritol ester is placed in a mechanical stirring tank and stirred for 7 minutes, and the temperature is controlled at 120°C, and stirred at a speed of 220r / min for 8 minutes. The evenly stirred plastic particles are sucked into the hopper of the single-screw extruder by ...

example 2

[0047] PE 80Kg

[0048] PP 25Kg

[0049] Modified Nano Calcium Carbonate 6Kg

[0050]Dicumyl peroxide 0.6Kg

[0051] Triallyl isocyanurate 1Kg

[0052] Tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythritol ester 0.15Kg

[0053] (1) Mix the silane coupling agent with the solution (water / ethanol volume ratio is 1:5);

[0054] (2) Mix calcium carbonate with a 7% mass ratio silane coupling agent solution evenly, and dry in vacuum for 13 hours at 80°C to obtain modified nano-calcium carbonate;

[0055] (3) Weigh the required mass according to the formula;

[0056] (4) Place PE / PP, dicumyl peroxide, triallyl isocyanurate, tetrakis(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol Stir in a mechanical stirring tank for 6 minutes, and control the temperature at 150°C, and stir for 9 minutes at a speed of 250r / min. The evenly stirred plastic particles are sucked into the hopper of the single-screw extruder by a vacuum suction machine, and the p...

example 3

[0058] PE 80Kg

[0059] PP 27Kg

[0060] Modified Nano Calcium Carbonate 6Kg

[0061] Dicumyl peroxide 0.7Kg

[0062] Triallyl isocyanurate 1.2Kg

[0063] Tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythritol ester 0.25Kg

[0064] (1) Mix the silane coupling agent with the solution (water / ethanol volume ratio is 1:5);

[0065] (2) Mix calcium carbonate with 8% by mass silane coupling agent solution evenly, and dry in vacuum for 15 hours at 80°C to obtain modified nano-calcium carbonate;

[0066] (3) Weigh the required mass according to the formula;

[0067] (4) Place PE / PP, dicumyl peroxide, triallyl isocyanurate, tetrakis(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol Stir in a mechanical stirring tank for 6 minutes, and control the temperature at 160°C, and stir at a speed of 300r / min for 10 minutes. The evenly stirred plastic particles are sucked into the hopper of the single-screw extruder by a vacuum suction machine. After the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com