Leather coating composition and preparation method thereof

A technology of leather coatings and compositions, which is applied in lignin coatings, leather surface treatment, antifouling/underwater coatings, etc., can solve the problems of environmental protection, poor embossing and setting, and complicated operations, so as to reduce production costs and improve production efficiency. Adhesive force, easy operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

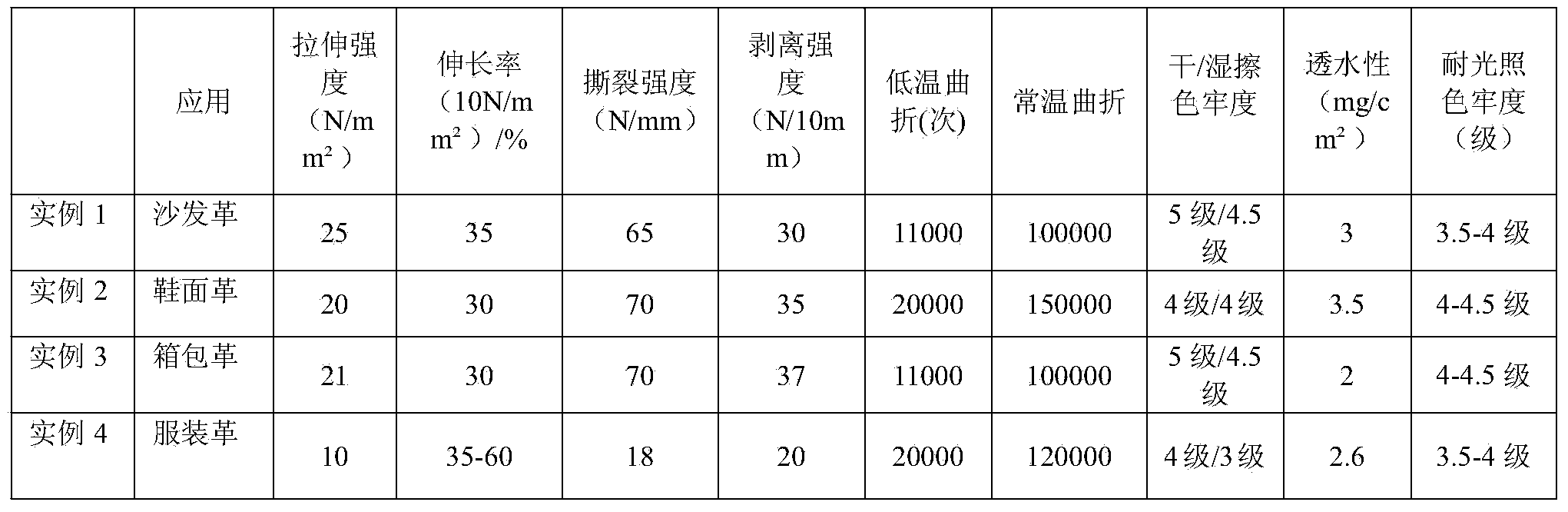

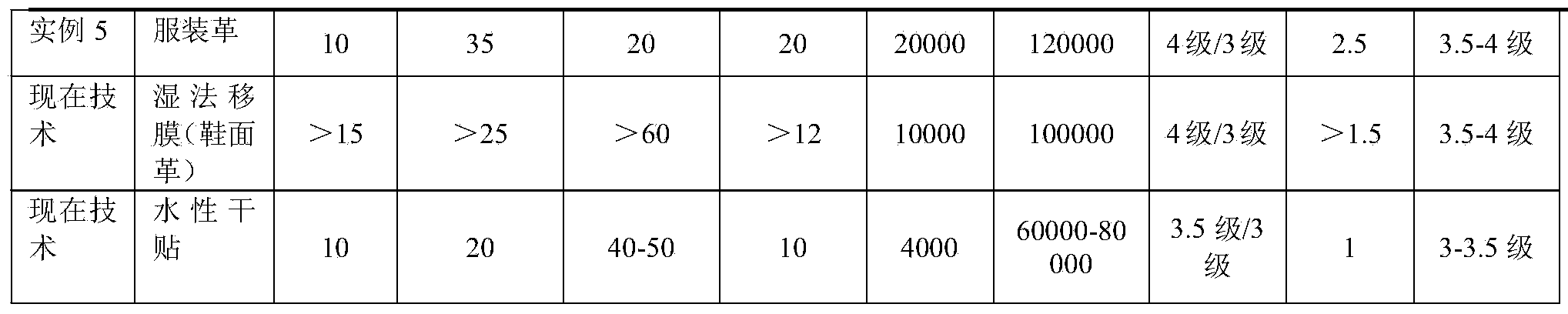

Examples

Embodiment 1

[0022] A kind of leather coating composition, this leather coating composition is directly used in two-layer leather leather sofa leather, comprises following component by weight percentage: acrylic resin 20%; Lignocellulose 10%; Silicon dioxide 5%; Feel 5% of wax; 8% of wax; 3% of foaming agent; 0.5% of antioxidant; 0.5% of curing agent; 1% of neutralizing agent; 2% of dispersant; 2% of wetting agent; %; essence 0.5%; hydroxyethyl cellulose 2%; water 38%.

[0023] This leather coating composition is directly used in two-layer leather embryo sofa leather, and its preparation method is:

[0024] ①Put water into the dispersion kettle, heat up to 50°C, then add bactericide, essence, leveling agent, wetting agent, dispersant and acrylic resin, and stir evenly;

[0025] ②Under continuous stirring, slowly add lignocellulose, silicon dioxide, wax, hand feeling agent and foaming agent, and keep stirring for 60 minutes to make them evenly dispersed in the system;

[0026] ③Under cont...

Embodiment 2

[0029] A kind of leather coating composition, the coating composition that is directly used in the coating composition of two-layer leather shoe upper leather, comprises the following components by weight percentage: acrylic resin 25%; Lignocellulose 10%; Silicon dioxide 10%; Hand feeling 2% wax; 12% wax; 1% foaming agent; 2% antioxidant; 3% curing agent; 2% neutralizing agent; 5% dispersant; 3% wetting agent; 1% leveling agent; defoamer 1%; fungicide 0.5%; essence 0.2%; hydroxyethyl cellulose 2%; water 20.3%.

[0030] The leather coating composition is directly used for two-layer leather shoe upper leather, and its preparation method is:

[0031] ①Put water into the dispersion kettle, heat up to 55°C, then add defoamer, bactericide, essence, leveling agent, wetting agent, dispersant and acrylic resin, and stir evenly;

[0032] ②Under continuous stirring, slowly add lignocellulose, silicon dioxide, wax, hand feeling agent and foaming agent, and keep stirring for 90 minutes to...

Embodiment 3

[0036] A leather coating composition, which is directly used for the first layer of poor leather embryo box leather, comprises the following components in weight percentage: 30% of acrylic resin; 8% of lignocellulose; 7% of silicon dioxide; 5% of hand feeling agent; Wax 15%; antioxidant 2%; curing agent 1%; neutralizer 1%; dispersant 2%; wetting agent 2%; leveling agent 2%; defoamer 1%; %; Hydroxyethylcellulose 0.5%; Water 22%.

[0037] The leather coating composition is directly used for the first layer of poor leather embryo luggage leather, and its preparation method:

[0038] ①Put water into the dispersion kettle, heat up to 52°C, then add defoamer, bactericide, flavor, leveling agent, wetting agent, dispersant and acrylic resin, and stir evenly;

[0039] ②Under continuous stirring, slowly add lignocellulose, silicon dioxide, wax and hand feeling agent, and keep stirring for 80 minutes to make them evenly dispersed in the system;

[0040] ③ Under continuous stirring, add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com