Cell culture apparatus

A cell culture and cell technology, applied in the fields of biology and medicine, can solve the problems of cumbersome operation, high consumption of reagents and manpower, and inability to realize the direct co-culture of two kinds of adherent cells, so as to achieve high design flexibility and promote growth. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

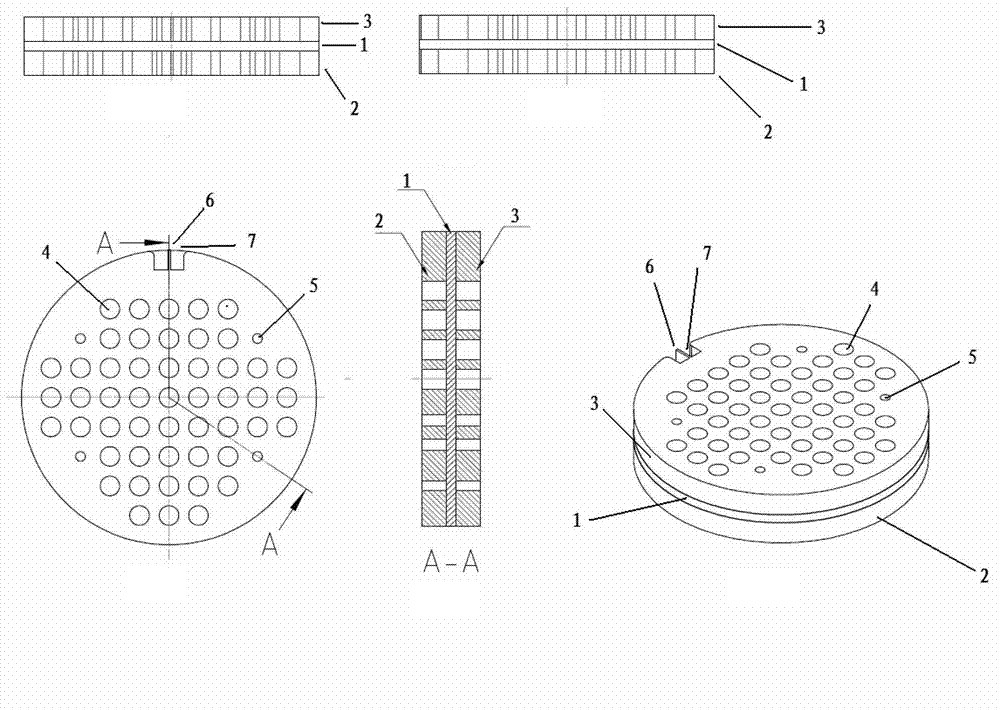

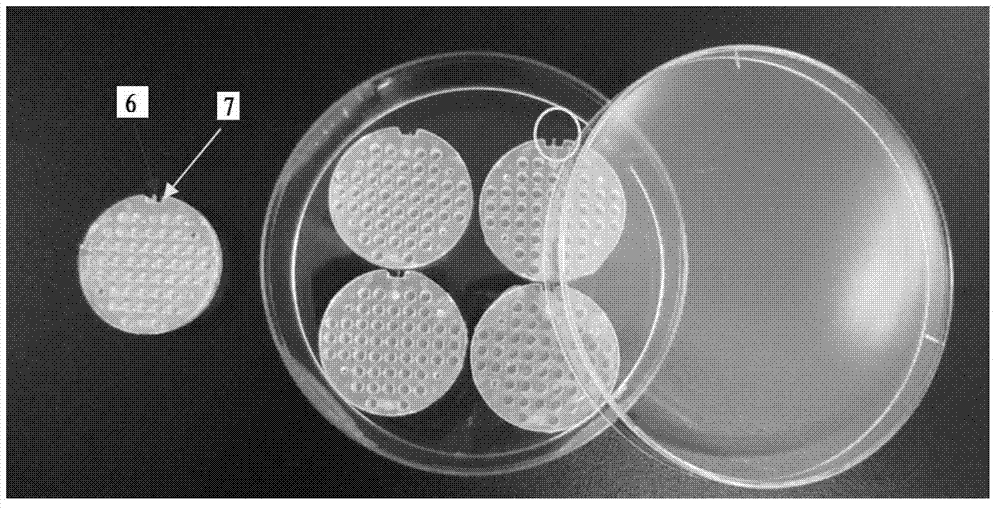

[0050] Embodiment 1: Preparation of the cell culture device of the present invention

[0051] The cell culture device used is composed of an upper substrate, a thin film and a lower substrate, forming a "sandwich" structure between the three. The upper base plate and the lower base plate are made of polystyrene material, and the appearance is a circular plate with a diameter of 3.3 cm. There are 120 connected cylindrical through holes on the upper substrate and the lower substrate respectively, the depth of the holes is 2 mm, and the diameter of the holes is 2 mm. There are four small cylinders on the lower surface of the upper substrate and the lower substrate respectively, with a height of 2mm and a diameter of 1.5mm. The upper surfaces of the upper substrate and the lower substrate each have four holes corresponding to the size and height of the small cylinders, so as to clamp the film . The film is a polyethylene terephthalate film (PET) with a pore size of 8 μm. The de...

Embodiment 2

[0052] Embodiment 2: Inoculation of NIH-3T3 cells

[0053] 1. Vaccination

[0054] Place the cell culture device prepared in Example 1 in a petri dish with a diameter of 35mm, and add a concentration of 2×10 6 NIH-3T3 cell suspension per mL, after the cell suspension penetrates into the well, add fresh medium from the side channel. The medium is flush with, but does not cover, the top surface of the device. After the cells attach to the wall, fresh medium is slightly added to cover the entire cell culture device for culture.

[0055] 2. Detachment

[0056] Place the culture dish equipped with the cell culture device at an ambient temperature of about 20 degrees Celsius for 10 minutes, and then observe the detached cell mass under a microscope ( Image 6 ), the cells in each well are aspirated and mechanically blown gently, which can be used for subsequent detection or expanded culture.

Embodiment 3

[0057] Example 3: Co-cultivation of adherent cell NIH-3T3 and cell HL-60

[0058] The size of the cell culture device used was the same as in Example 1, except that the middle membrane was replaced by a polycarbonate membrane with a pore size of 5 μm. The surface of the film was not treated, and the upper substrate, film and lower substrate were assembled together, soaked in 75% ethanol for sterilization, and air-dried in an ultra-clean bench.

[0059] Set the concentration to 2 x 10 6 NIH-3T3 cells / mL were inoculated on the bottom of a 35 mm-diameter petri dish. After 24 hours, the medium was removed and the surface was rinsed with PBS. Then put the sterilized and air-dried above-mentioned cell culture device into it, and put the concentration of 2×10 5 Each / mL HL-60 cell suspension was dropped on the surface of the device, and after the cell suspension completely penetrated into the well, fresh medium was added from the side channel. The total volume of medium is flush wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com