Metal nanoparticle-PCP complex and manufacturing method therefor

A technology of metal nanoparticles and manufacturing methods, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of limited composite effect of metal nanoparticles and PCP, and achieve the effect of high degree of freedom and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

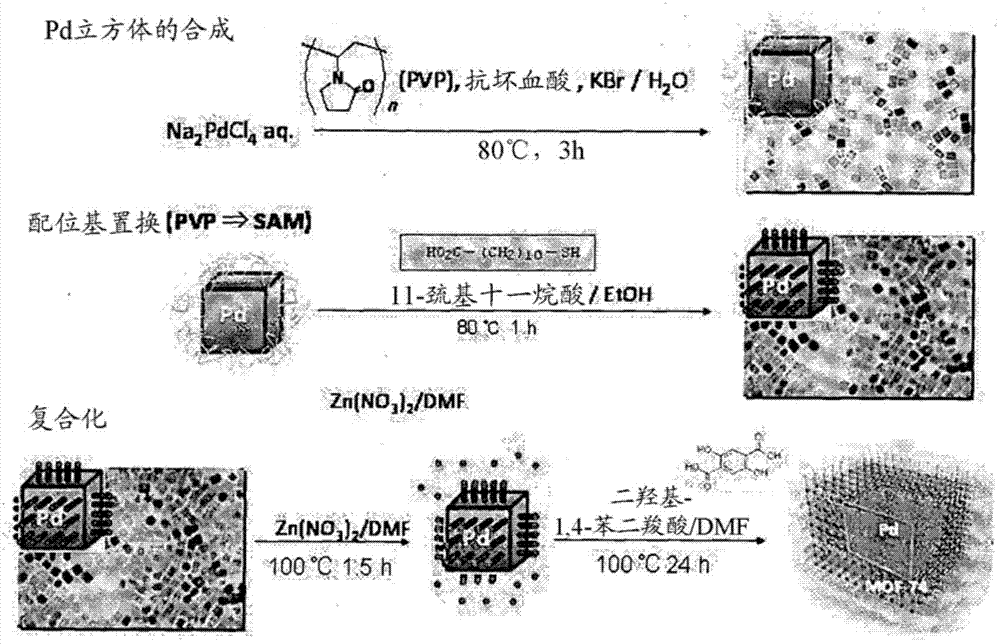

[0082] (1) Synthesis of Pd cubes ( figure 1 )

[0083] Combination with PCP was studied using cubic active metal species (Pd).

[0084] Cubic Pd is obtained by adding polyvinylpyrrolidone (PVP; 105mg), ascorbic acid (60mg) and KBr (300mg) to Na2PdCl4 aqueous solution (17.4mM), and reducing at 80°C for 3 hours to obtain Pd nanoparticles with PVP attached to the surface (10nm).

[0085] (2) Ligand replacement (PVP→SAM)

[0086] Add HOOC-(CH 2 ) 10 -SH (70mg) in ethanol, reacted at 80°C for 1 hour, so that HOOC-(CH 2 ) 10 -SH is bonded to the Pd particle via the SH group.

[0087] HOOC-(CH 2 ) 10 -SH accumulates PCP from the surface of the active metal species, so it replaces the metal (Pd) surface with a self-assembled monomolecular film (SAM) having the same functional group (COOH) as the ligand component of PCP at the end And used.

[0088] (3) Composite

[0089] Add Zn(NO 3 ) 2 / DMF (40mg), reacted at 100°C for 1.5 hours, and bonded Zn ions to HOOC-(CH 2 ) 10 ...

Embodiment 2

[0094] The composite obtained in Example 1 was used as an electrode catalyst to carry out formic acid oxidation reaction. Add 2.5 mg of cubic active metal species and 2.5 mg of carbon paste (CPO) to the composite to 11.5 μl of ethanol and 11.5 μl of “Nafion (registered trademark)” [manufactured by DuPont, 10 times the solid content concentration of 5% by mass] Diluted sample] in a mixed solvent, irradiated with ultrasonic waves to make a suspension. Apply 23 μL of the suspension to a glassy carbon electrode [diameter 3 mm, electrode area 7.1 mm 2 ], dried to obtain a modified electrode. The modified electrode is immersed in a mixed solution of sulfuric acid with a concentration of 0.5M and 1.0M formic acid, and at room temperature, atmospheric pressure, and argon atmosphere, the potential of the silver-silver chloride electrode is scanned in the range of -0.1 to 1.00V, A scan rate of 10 mV / s cycles the potential. The results are shown in Figure 6 .

[0095] Similar to Do...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com