Black bone chicken powder and preparation method thereof

A technology of black-bone chicken powder and black-bone chicken, which is applied in the food field, can solve the problems of aroma intensity, fullness and weak cooking feeling, high price of pure black-bone chicken powder, loss of flavor components, etc., achieve recovery and aroma intensity and fullness, and enhance flavor Stability, aroma-intensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

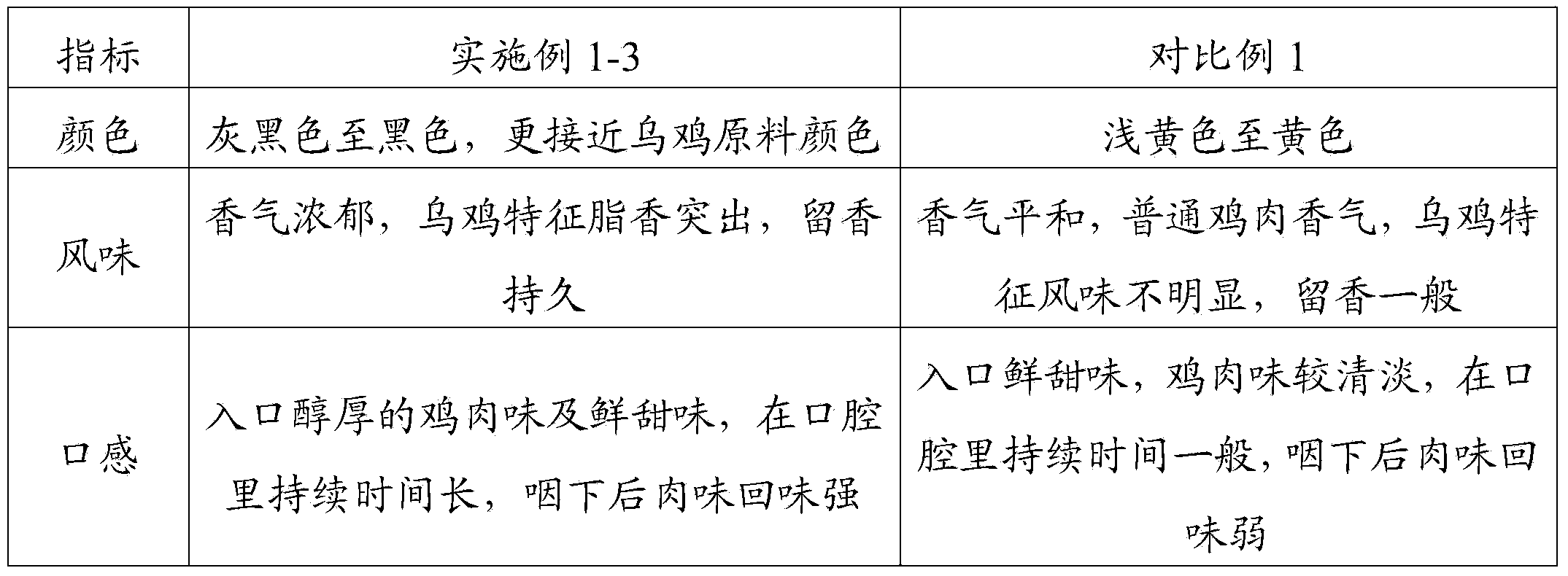

Examples

Embodiment 1

[0036] A kind of black-bone chicken powder is mainly prepared from the raw materials of following weight:

[0037] The first part: black chicken 352g, water 47g, Novozymes protease 1g;

[0038] The second part: edible glucose 23g, D-xylose 1.5g, glycine 3.5g, L-cysteine 4.5g, DL-methionine 1.8g, chicken oil 75g, salt 28g;

[0039] The third part: 77g of table salt, 27.5g of white sugar, 62g of monosodium glutamate, 3.1g of I+G, 1.5g of disodium succinate, 62.5g of maltodextrin, 62.5g of sodium starch octenyl succinate, glyceryl monostearate 1g, water 100g.

[0040] The preparation method of above-mentioned black-bone chicken powder, comprises the steps:

[0041] (1) Weigh raw materials according to the above mass: 352g of black-bone chicken meat, 47g of water, put them into the reaction tank and cook for 120 minutes at a temperature of 122°C, cool and beat, add Novozymes protease 1g, keep warm for 60 minutes at 55°C for enzymatic hydrolysis . After enzymatic hydrolysis, ...

Embodiment 2

[0045] A kind of black-bone chicken powder is mainly prepared from the raw materials of following weight:

[0046] The first part: 340g of black-bone chicken meat, 40g of water, 0.9g of proteolytic enzyme;

[0047] The second part: edible glucose 20g, D-xylose 1.6g, glycine 3g, L-cysteine 4g, DL-methionine 1.5g, chicken oil 70g, salt 20g;

[0048] The third part: 70g of table salt, 23g of white sugar, 55g of monosodium glutamate, 2.5g of I+G, 1.3g of disodium succinate, 70g of maltodextrin, 55g of sodium starch octenyl succinate, 1g of glyceryl monostearate, water 90g,

[0049] The preparation method of above-mentioned black-bone chicken powder, comprises the steps:

[0050] (1) Weigh the raw materials according to the above mass: 340g of black-bone chicken meat, 40g of water, put them into the reaction tank and cook for 110 minutes at 120°C, cool and beat, add 0.9g of Novozymes protease, and keep warm at 54°C for enzymatic hydrolysis for 60 minute. After enzymatic hydro...

Embodiment 3

[0054] A kind of black-bone chicken powder is mainly prepared from the raw materials of following weight:

[0055] The first part: 365g of black-bone chicken meat, 50 parts of water, 1.1g of proteolytic enzyme;

[0056] The second part: edible glucose 25g, D-xylose 1.4g, glycine 4g, L-cysteine 5g, DL-methionine 2g, chicken oil 80g, salt 36g;

[0057] The third part: 84g of table salt, 32g of white sugar, 69g of monosodium glutamate, 3.5g of I+G, 1.7g of disodium succinate, 70g of maltodextrin, 70g of sodium starch octenyl succinate, 1g of glyceryl monostearate, 110g of water.

[0058] The preparation method of above-mentioned black-bone chicken powder, comprises the steps:

[0059] (1) Weigh the raw materials according to the above mass: 365g of black-bone chicken meat, 50g of water, put them into the reaction tank and cook for 130 minutes at 125°C, cool and beat, add Novozymes protease 1.1g, keep warm and enzymatically hydrolyze at 57°C for 60 minute. After enzymatic hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com