NaInO2 photocatalyst and preparation method thereof

A technology of photocatalyst and sodium acetate, which is applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of low quantum efficiency and large band gap, To achieve the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

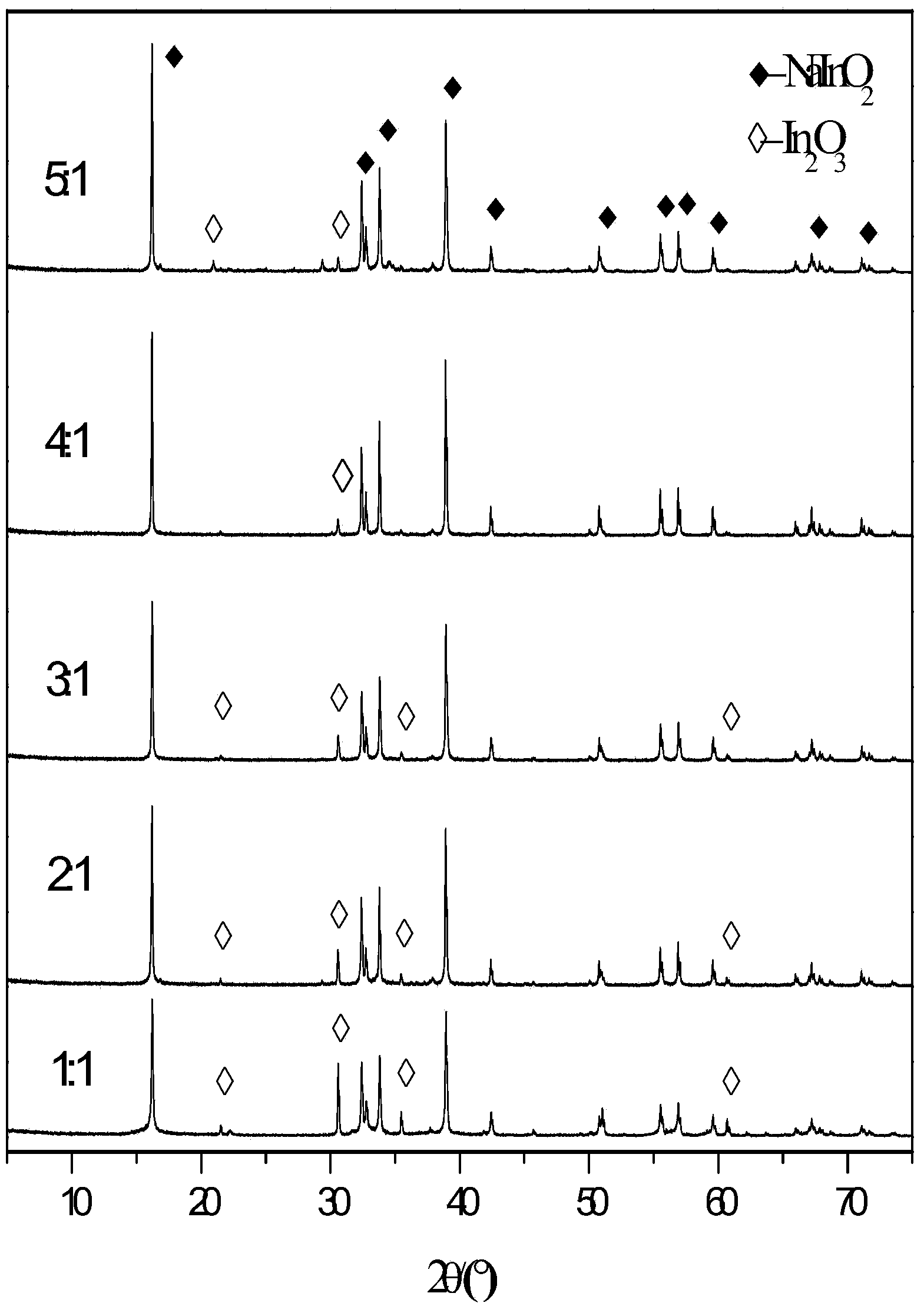

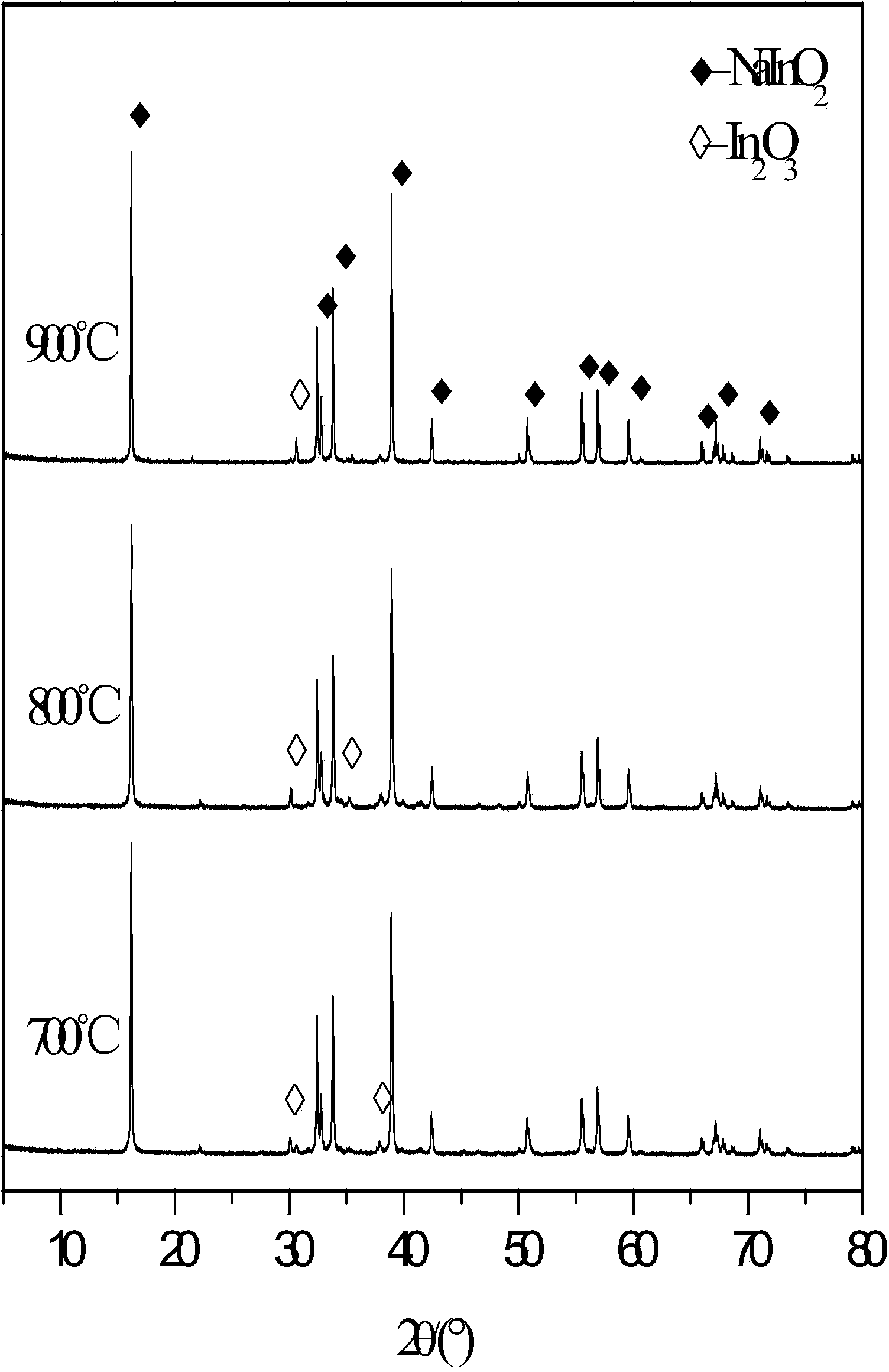

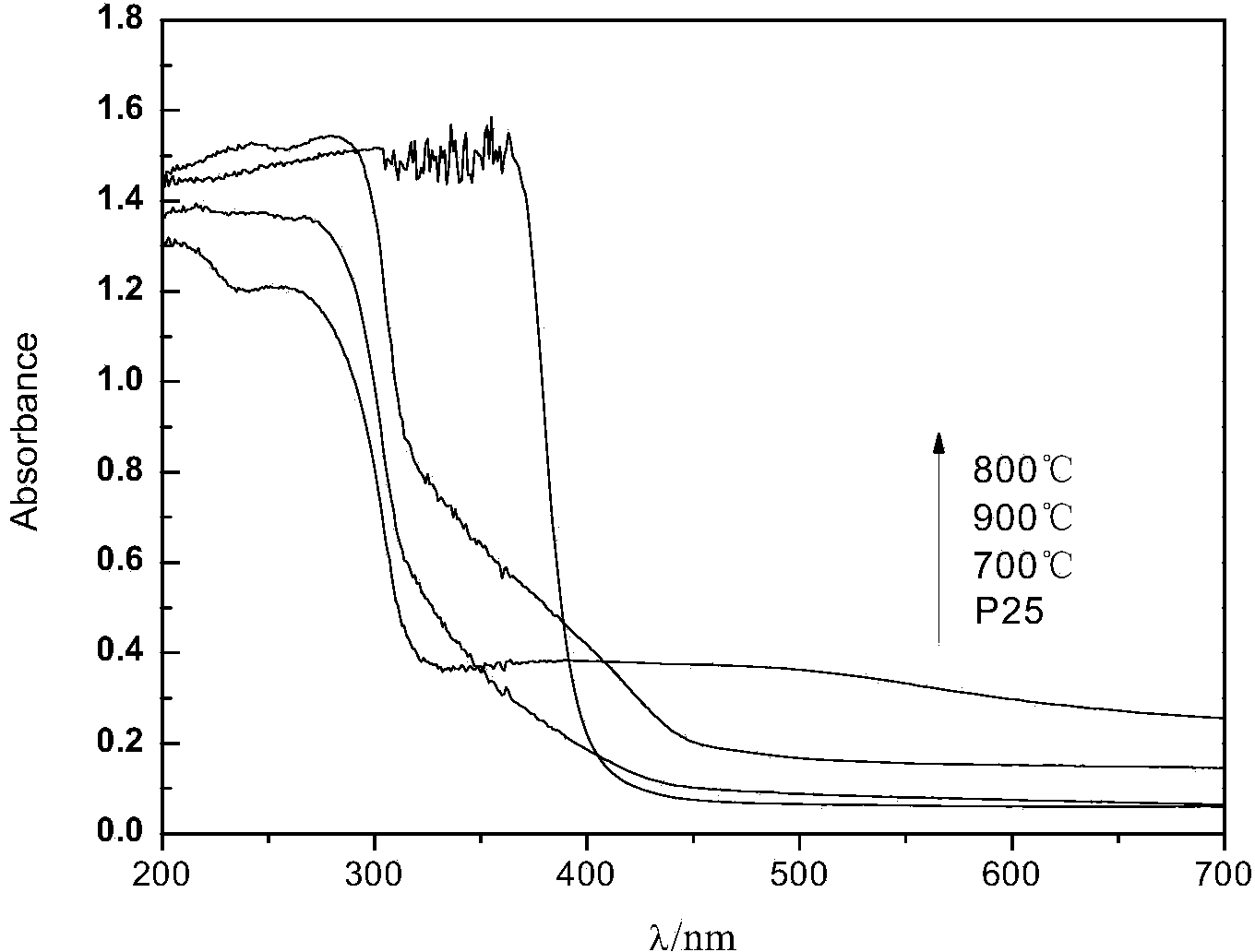

Embodiment 1

[0027] Accurately weigh 4.0832g CH 3 COONa·3H 2 O and 11.4556g In(NO 3 ) 3 4.5H 2 O mixed in a 300mL beaker (CH 3 COONa·3H 2 O and In(NO 3 ) 3 4.5H 2 O molar ratio is 1:1), add 60mL ethylene glycol as a solvent, and stir electrically for 8 hours in a water bath at 60-70°C to form a sol-gel system; place the sol-gel in a constant temperature drying oven at 150°C The precursor was dried at lower temperature to obtain the precursor; the precursor was calcined in a muffle furnace at 900°C for 8 hours, cooled naturally and ground into powder to obtain NaInO 2 catalyst of light.

Embodiment 2

[0029] Accurately weigh 8.1690g CH 3 COONa·3H 2 O and 11.4525g In(NO 3 ) 3 4.5H 2 O mixed in a 300mL beaker (CH 3 COONa·3H 2 O and In(NO 3 ) 3 4.5H 2 O molar ratio is 1:2), add 60mL ethylene glycol as a solvent, and stir electrically for 8 hours in a water bath at 60-70°C to form a sol-gel system; place the sol-gel in a constant temperature drying oven, The precursor was dried at lower temperature to obtain the precursor; the precursor was calcined in a muffle furnace at 900°C for 8 hours, cooled naturally and ground into powder to obtain NaInO 2 catalyst of light.

Embodiment 3

[0031] Accurately weigh 6.1235g CH 3 COONa·3H 2 O and 5.7260g In(NO 3 ) 3 4.5H 2 O mixed in a 300mL beaker (CH 3 COONa·3H 2 O and In(NO 3 ) 3 4.5H 2 O molar ratio is 1:3), add 60mL of ethylene glycol as solvent, electric stirring in a water bath at 60-70°C for 8h to form a sol-gel system; put the sol-gel in a constant temperature drying oven, The precursor was dried at lower temperature to obtain the precursor; the precursor was calcined in a muffle furnace at 900°C for 8 hours, cooled naturally and ground into powder to obtain NaInO 2 catalyst of light.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com