Copolymerization modified ordered mesoporous carbon nitride photocatalyst

A technology of porous carbon nitride light and porous carbon nitride is applied in the field of copolymerization modified ordered mesoporous carbon nitride photocatalyst and its preparation, which can solve the problem of reducing the visible spectrum response and utilization, and the forbidden band of carbon nitride semiconductor. The width becomes larger and other problems, to achieve the effect of expanding the light absorption range, accelerating the mass transfer and diffusion process, and the preparation method is simple and feasible

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

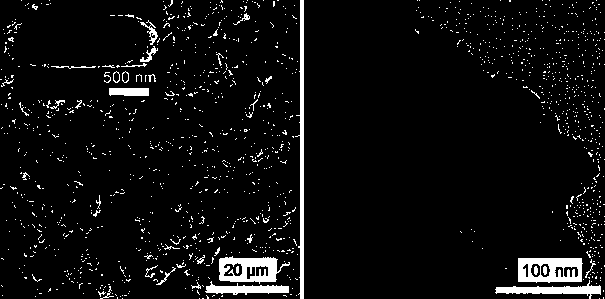

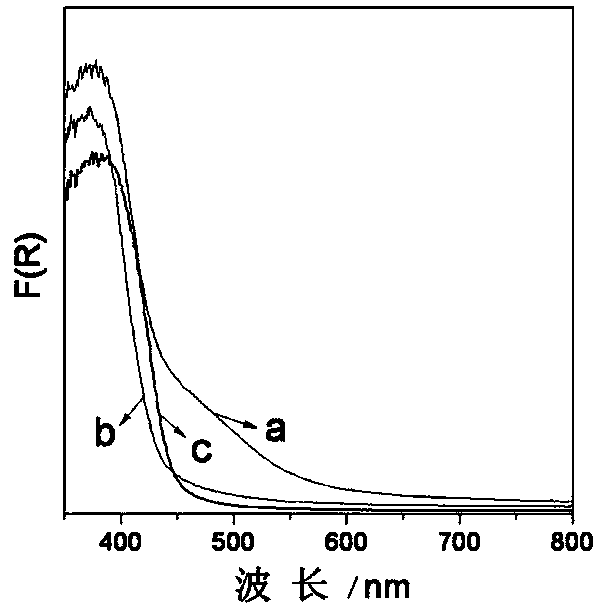

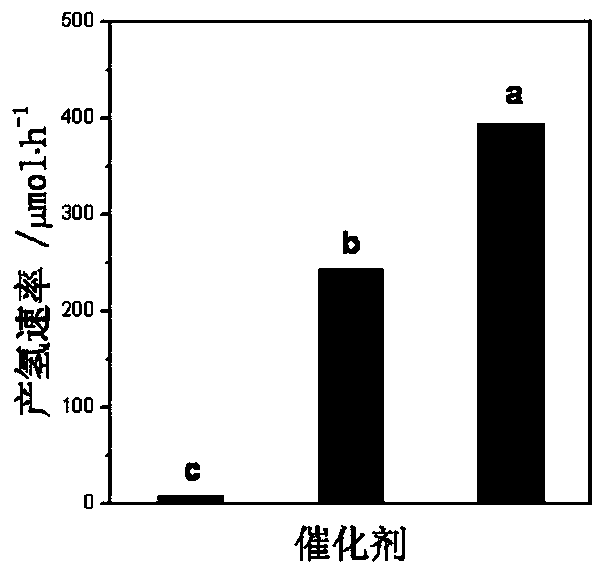

Image

Examples

Embodiment 1

[0025] Stir the mixture of soft template agent and hydrochloric acid solution (concentration: 1.6 mol / L) at a ratio of 1g:8mL at 45°C until the solution is clear and transparent, add silicon source (P123:TEOS=1g:1.9g), and continue stirring 18h, hydrothermal crystallization at 140°C for 24h, washing and drying, calcination at 450°C for 8h to remove organic matter, and obtain SBA-15 ordered mesoporous silica.

[0026] Add 10 times the amount of the silicon dioxide obtained above to a hydrochloric acid solution with a concentration of 2.0 mol / L, heat and stir at 80° C. for 24 hours, centrifuge, and dry to obtain an acidified silicon dioxide hard template.

[0027] Put the mixture of the precursor step and the above-mentioned acidified silica in a flask (the mass ratio of cyanamide, 3-aminothiophene-2-carbonitrile, and silica template is 10: 0.1: 1), at 50 Under the condition of heating at ℃, ultrasonically and vacuumize the mixture (vacuum degree <1kPa) for 6h, add 20mL of water...

Embodiment 2

[0029] Stir the mixture of 1g:5mL soft template agent and hydrochloric acid solution (concentration: 1.6 mol / L) at 35°C until the solution is clear and transparent, add silicon source (P123:TEOS=1g:1.1g), and continue stirring 12h, hydrothermal crystallization at 120°C for 24h, washing and drying, calcination at 450°C for 6h to remove organic matter, and obtain SBA-15 ordered mesoporous silica.

[0030] Add 25 times the amount of the silicon dioxide obtained above to a hydrochloric acid solution with a concentration of 1.0 mol / L, heat and stir at 80° C. for 16 hours, centrifuge, and dry to obtain an acidified silicon dioxide hard template.

[0031] Put the mixture of the precursor step and the above-mentioned acidified silica in a flask (the mass ratio of cyanamide, 3-aminothiophene-2-carbonitrile, and silica template is 4: 0.0013: 1), at 55 Under the condition of heating at ℃, ultrasonically and vacuumize the mixture (vacuum degree <1kPa) for 4h, add 15mL water to wash and ce...

Embodiment 3

[0033]Stir the mixture of soft template agent and hydrochloric acid solution (concentration: 1.6 mol / L) at a ratio of 1g: 11mL at 35°C until the solution is clear and transparent, add silicon source (P123: TEOS = 1g: 1.6g), and continue stirring 24h, at 150 o C for hydrothermal crystallization for 24 hours, washed and dried, and calcined at 550°C for 4 hours to remove organic matter to obtain SBA-15 ordered mesoporous silica.

[0034] Add 20 times the amount of the silicon dioxide obtained above to a hydrochloric acid solution with a concentration of 1.0 mol / L, heat and stir at 80° C. for 12 hours, centrifuge, and dry to obtain an acidified silicon dioxide hard template.

[0035] Place the mixture of the precursor step and the above-mentioned acidified silica in a flask (the mass ratio of cyanamide, 3-aminothiophene-2-carbonitrile, and silica template is 8: 0.005: 1), at 55 Under the condition of heating at ℃, ultrasonically and vacuumize the mixture (vacuum degree <1kPa) for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com