Total ultraviolet-proof automobile film and manufacturing method thereof

A technology of anti-ultraviolet and manufacturing method, applied in the field of optical film, can solve the problems of skin aging, skin light damage, weak long-wave blocking ability, etc., and achieve the effects of avoiding damage, long service life and good clarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

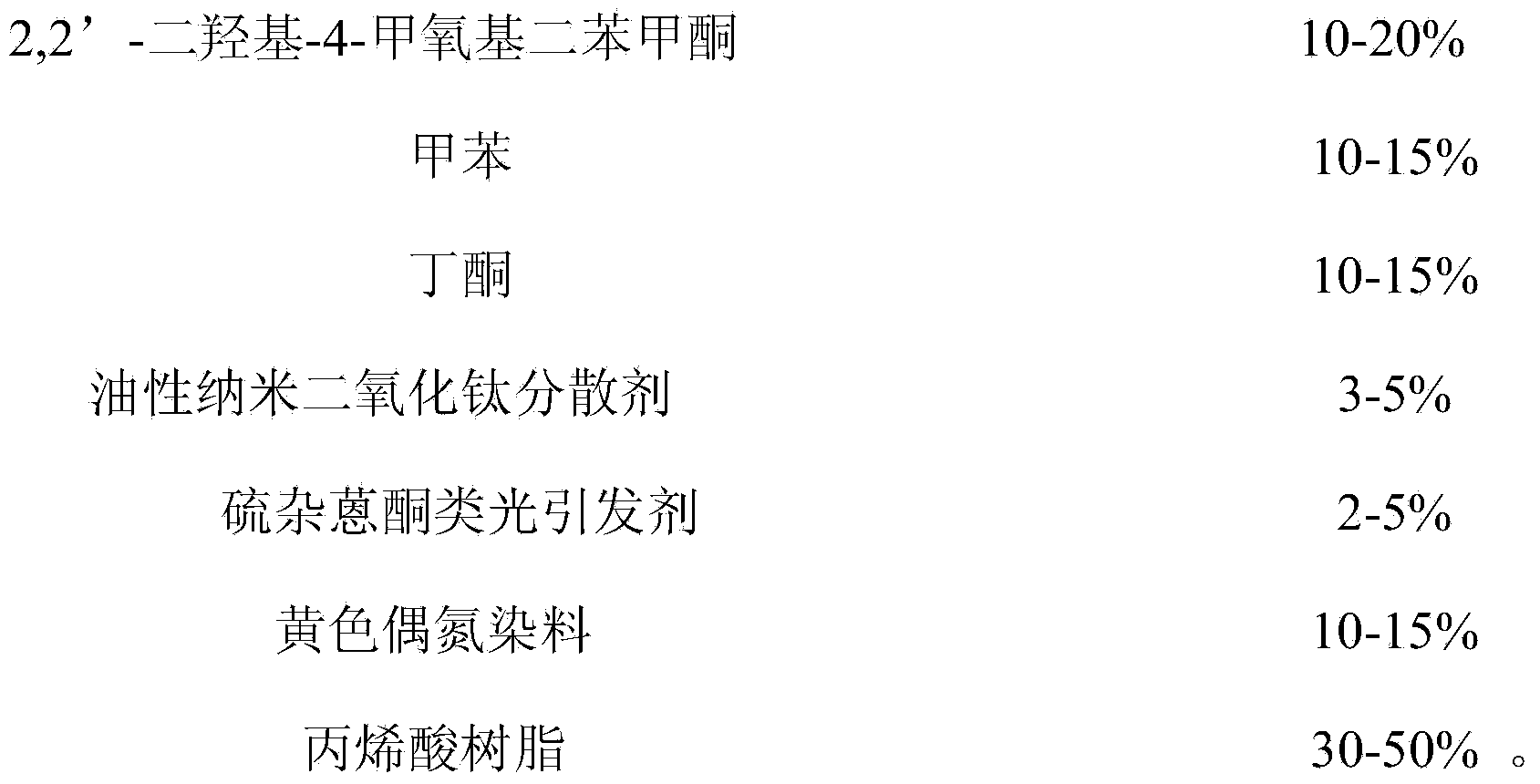

[0025] The full anti-ultraviolet automotive film includes a PET composite film, a PET protective film, a PET coating film between the PET composite film and the PET protective film, and the side of the PET coating film that is in contact with the PET composite film is coated with uv400 full anti-ultraviolet slurry, the side of the PET coating film in contact with the PET protective film is coated with adhesive, the uv400 full anti-ultraviolet slurry is composed of the following components and the mass fraction of each component is:

[0026]

[0027]

[0028] A kind of manufacture method of full anti-ultraviolet automobile film, comprises the following steps:

[0029] Step 1: mixing toluene and butanone;

[0030] Step 2: Dissolving 2,2'-dihydroxy-4-methoxybenzophenone in the mixed solution of step 1;

[0031] Step 3: Add oily nano-titanium dioxide dispersant and stir to disperse;

[0032] Step 4: adding a thioxanthone photoinitiator and a yellow azo dye and stirring;

...

Embodiment 2

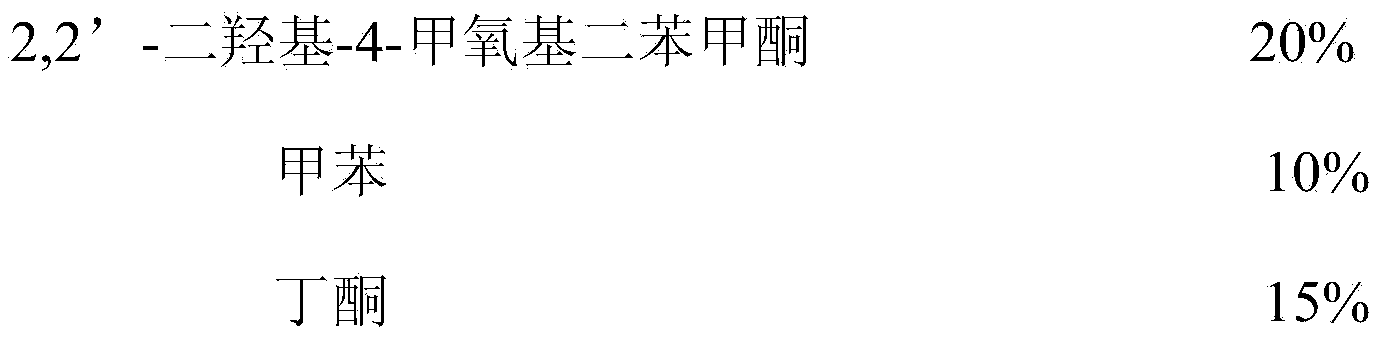

[0039] The full anti-ultraviolet automotive film includes a PET composite film, a PET protective film, a PET coating film between the PET composite film and the PET protective film, and the side of the PET coating film that is in contact with the PET composite film is coated with uv400 full anti-ultraviolet slurry, the side of the PET coating film in contact with the PET protective film is coated with adhesive, the uv400 full anti-ultraviolet slurry is composed of the following components and the mass fraction of each component is:

[0040]

[0041] Compared with Example 1, the consumption of ultraviolet absorber and photoinitiator is reduced, and the consumption of acrylic resin is increased, under the situation that guaranteed 100% absorptivity to ultraviolet rays, further improved the anti-explosion effect to automobile glass,

Embodiment 3

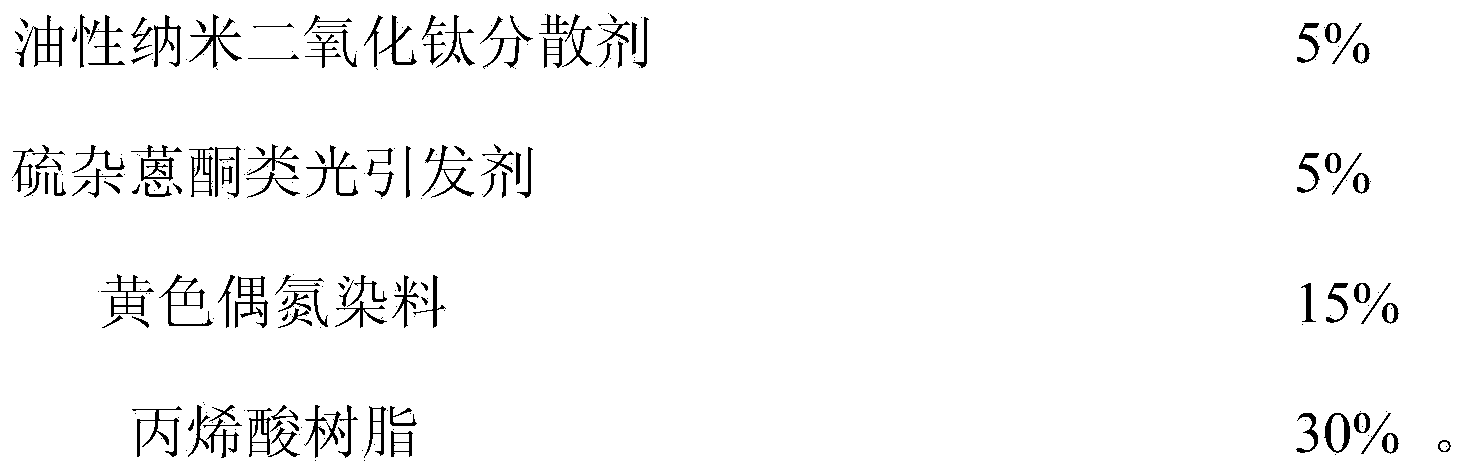

[0043] The full anti-ultraviolet automotive film includes a PET composite film, a PET protective film, a PET coating film between the PET composite film and the PET protective film, and the side of the PET coating film that is in contact with the PET composite film is coated with uv400 full anti-ultraviolet slurry, the side of the PET coating film in contact with the PET protective film is coated with adhesive, the uv400 full anti-ultraviolet slurry is composed of the following components and the mass fraction of each component is:

[0044]

[0045]

[0046] Compared with the above two embodiments, the amount of acrylic resin is the largest, the explosion-proof effect is the best, and the 100% absorption rate of ultraviolet rays is also realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com