Distiller's grain-based reinforcing material for wood-based panels and distiller's grain-based formaldehyde-free glue prepared from it

A reinforcing material and distiller's grain-based technology, which is applied to the preparation of adhesives, animal glue or gelatin, and the types of adhesives, can solve the problems of increased production costs, high prices, and low bonding strength, and achieve easy preservation, rich sources, and Ease of preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

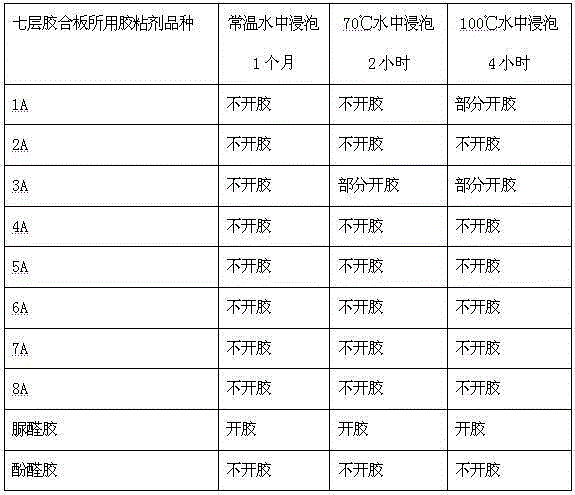

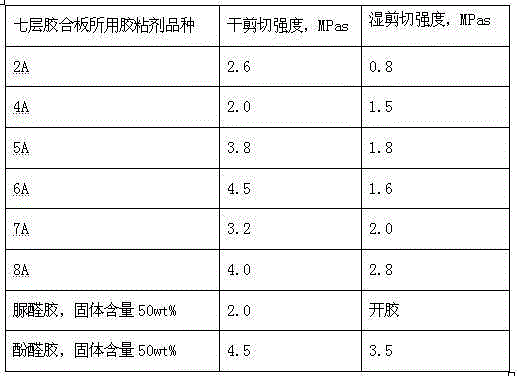

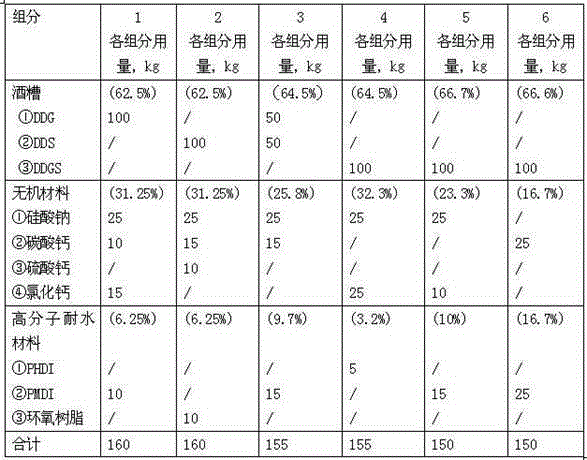

[0016] Example 1 Preparation of distiller's grains-based reinforcing materials 1-6 for wood-based panels

[0017] ① Formula

[0018] The percentage by weight of each component of the distiller's grains-based reinforcing material for wood-based panels in the present invention is as follows: 50-90% of distiller's grains, 10-35% of inorganic materials, 1-20% of polymer water-resistant materials, and the weight percentages of the above-mentioned components The sum is 100%; the inorganic material is calcium compound and / or silicate, and the weight ratio of calcium compound to silicate is 1:0-4; the specific formula is shown in Table 1.

[0019] Table 1

[0020]

[0021] Note 1: The data in brackets is the weight percentage of this component in the distiller's grain-based reinforcing material.

[0022] Note 2: Dried whole distiller's grains DDGS, dried distiller's grains DDG, and dried distiller's grains solubles DDS are all by-products of corn starch fermentation to produce al...

Embodiment 2

[0025] Example 2 Preparation of distiller's grains-based formaldehyde-free glue

[0026] The distiller's grains-based formaldehyde-free glue of the present invention is prepared by stirring and mixing 20-50 wt % of distiller's grains-based reinforcing material for wood-based panels, 0.1-5 wt % of additives, and the balance of water; One or more of foaming agent, wet strength agent and curing agent.

[0027] ①Preparation of distiller's grains-based formaldehyde-free glue 1A~6A

[0028] Weigh 35 kg of distiller's grains-based reinforcing materials 1 to 6 prepared in Example 1, add them to 64.9 kg of water, stir in a shearing machine in the coating industry, and stir at a speed of 300 rpm for 1 hour, then add 0.1kg of silicone oil defoamer (brand FAG470, product of Union Carbide Corporation), stirred at a speed of 100 rpm for 1 hour and then left to stand to prepare distiller's grains-based formaldehyde-free glues 1A to 6A respectively

[0029] ②Preparation of distiller's grain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com