Single-substrate white-light fluorescent powder for white-light LEDs (light-emitting diodes) and preparation method thereof

A fluorescent powder and white light technology, which is applied in the field of single-matrix white light fluorescent powder and its preparation, can solve the problem of low luminous efficiency, and achieve the effects of uniform particle size, environmental friendliness, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A single-matrix white light phosphor for white light LEDs and a preparation method thereof, comprising the following steps:

[0029] 1) Weigh Na 2 CO 3 , La 2 o 3 , Mg(NO 3 ) 2 ·6H2 O. WO 3 、Tm 2 o 3 、Dy 2 o 3 and Eu 2 o 3 , and the above raw materials are mixed and ground to obtain a mixed powder;

[0030] 2) Put the mixed powder in an alumina crucible and sinter in a resistance furnace. The sintering system in the resistance furnace is to raise the temperature to 200°C at a rate of 1°C / min, then raise the temperature to 500°C at a rate of 3°C / min, then raise the temperature to 1000°C at a rate of 5°C / min, keep the temperature for 3 hours, and finally cool with the furnace , to get NaLaMgWO 6 :xTm 3+ ,yDy 3+ , zEu 3+ White light phosphor, where x=0.07, y=0.01, z=0.01.

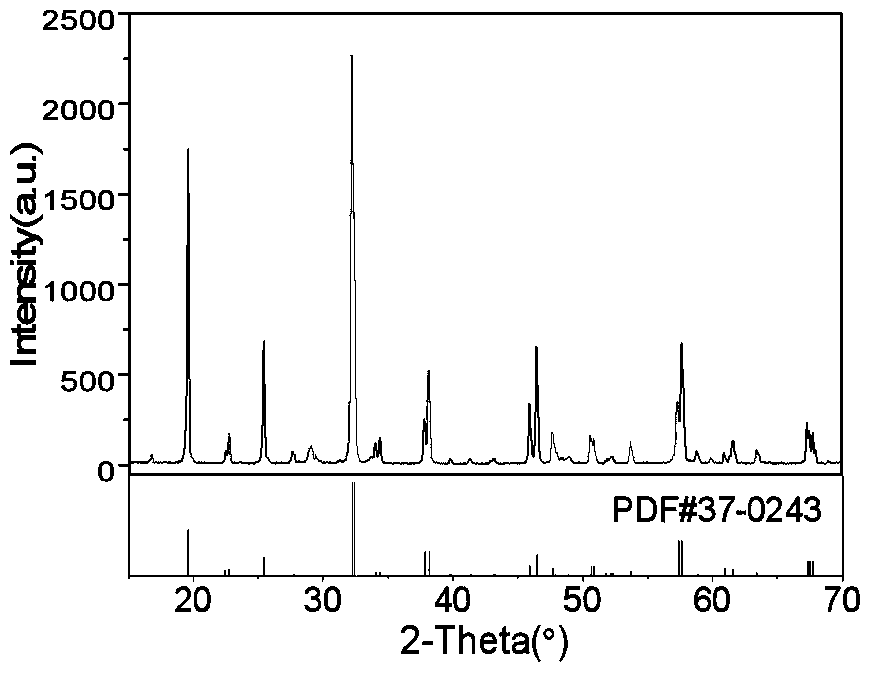

[0031] see figure 1 ,from figure 1 It can be seen that NaLaMgWO 6 :xTm 3+ ,yDy 3+ , zEu 3+ Powder and NaLaMgWO 6 The standard card JCPDS#37-0243 is completely consistent, and th...

Embodiment 2

[0033] A single-matrix white light phosphor for white light LEDs and a preparation method thereof, comprising the following steps:

[0034] 1) According to the molar ratio of 0.5:0.5:2:1:x / 2:y / 2:z / 2 (x=0.15, y=0.03, z=0.03), respectively weigh Na 2 CO 3 , La 2 o 3 , Mg(NO 3 ) 2 ·6H 2 O. WO 3 、Tm 2 o 3 、Dy 2 o 3 and Eu 2 o 3 , and the above raw materials are mixed and ground to obtain a mixed powder;

[0035] 2) Put the mixed powder in an alumina crucible and sinter in a resistance furnace. The sintering system in the resistance furnace is to heat up to 100°C at a rate of 1°C / min, then to 300°C at a rate of 2°C / min, and then to 1100°C at a rate of 7°C / min, hold for 3 hours, and finally cool with the furnace , to get NaLaMgWO 6 :xTm 3+ ,yDy 3+ , zEu 3+ White light phosphor, where x=0.15, y=0.03, z=0.03.

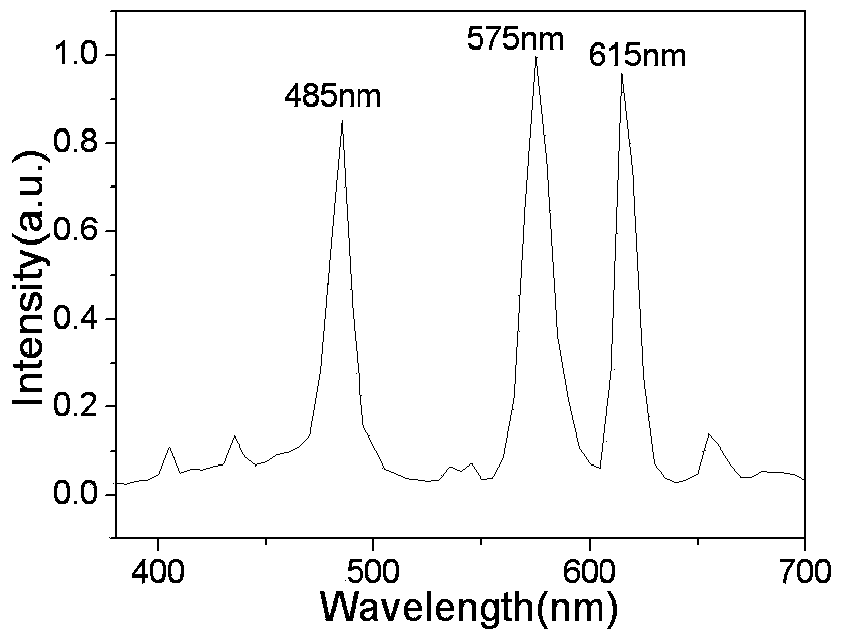

[0036] see figure 2 ,from figure 2 It can be seen that the emission bands of the phosphor are distributed in the range of 450nm to 650nm, and the emissio...

Embodiment 3

[0038] A single-matrix white light phosphor for white light LEDs and a preparation method thereof, comprising the following steps:

[0039] 1) According to the molar ratio of 1:2:0.5:1:x / 2:y / 2:z / 2 (x=0.2, y=0.05, z=0.05), respectively weigh Na 2 CO 3 , La 2 o 3 , Mg(NO 3 ) 2 ·6H 2 O. WO 3 、Tm 2 o 3 、Dy 2 o 3 and Eu 2 o 3 , and the above raw materials are mixed and ground to obtain a mixed powder;

[0040] 2) Put the mixed powder in an alumina crucible and sinter in a resistance furnace. The sintering system in the resistance furnace is to heat up to 300°C at a rate of 3°C / min, then to 600°C at a rate of 4°C / min, and then to 1100°C at a rate of 5°C / min, hold for 5 hours, and finally cool with the furnace , to get NaLaMgWO 6 :xTm 3+ ,yDy 3+ , zEu 3+ White light phosphor, where x=0.2, y=0.05, z=0.05.

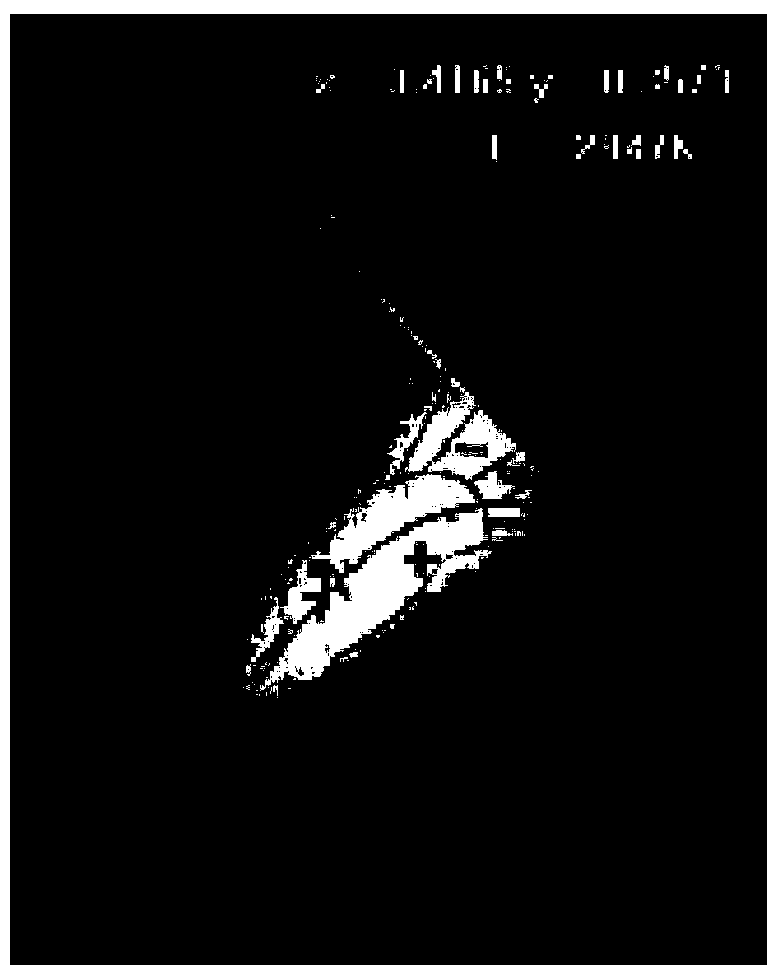

[0041] see image 3 ,from image 3 It can be seen that NaLaMgWO 6 :xTm 3+ ,yDy 3+ , zEu 3+ The phosphor powder emits white light under the excitation of ne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

| color rendering index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com