Method for modifying tung oil methyl esters by utilizing ultrasonic wave

A biodiesel and ultrasonic technology, applied in the chemical/physical/physicochemical process of energy application, biofuel, petroleum industry, etc., to improve high dynamic viscosity, high iodine value, high oil content, reduce energy and time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

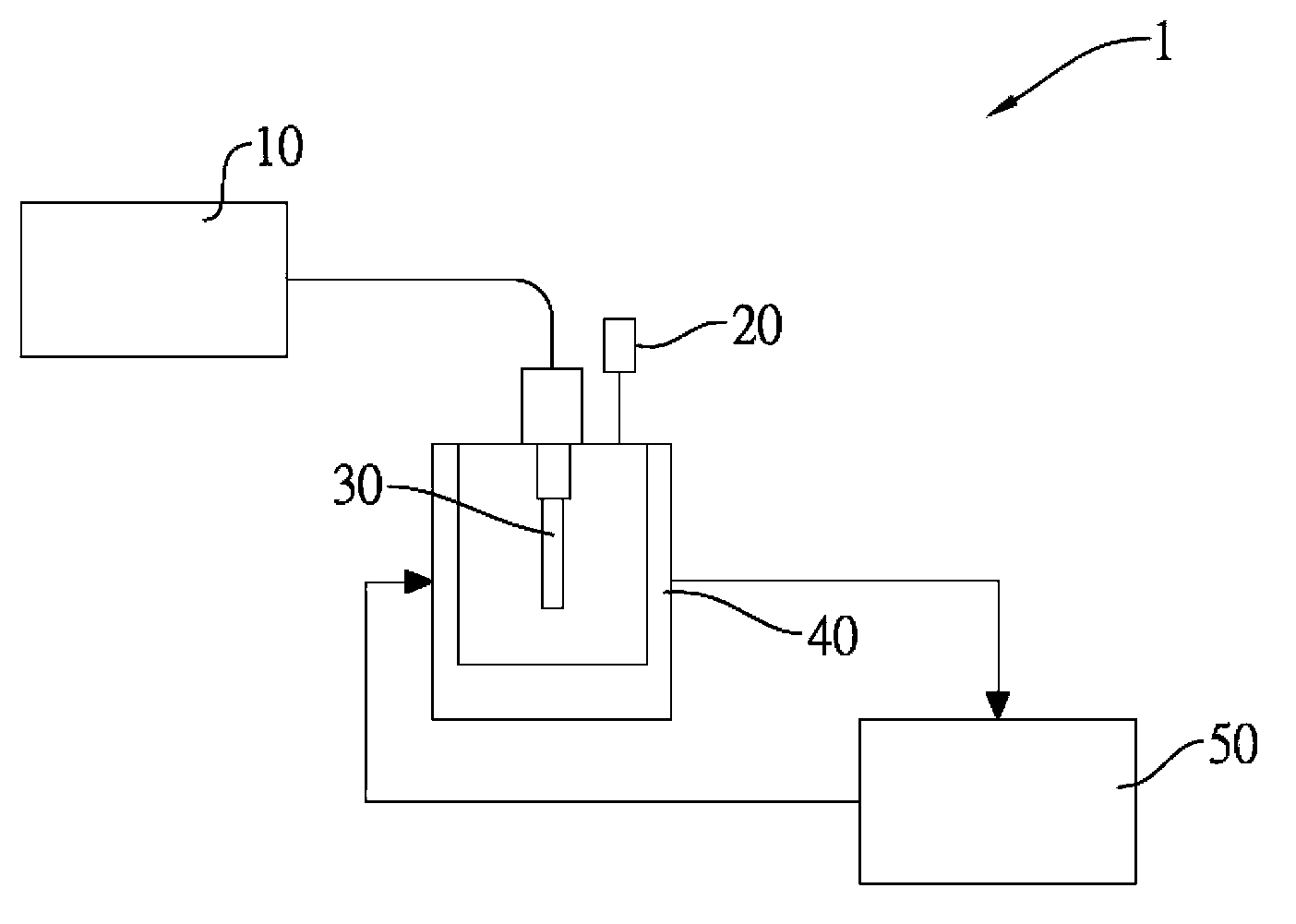

Method used

Image

Examples

Embodiment 1

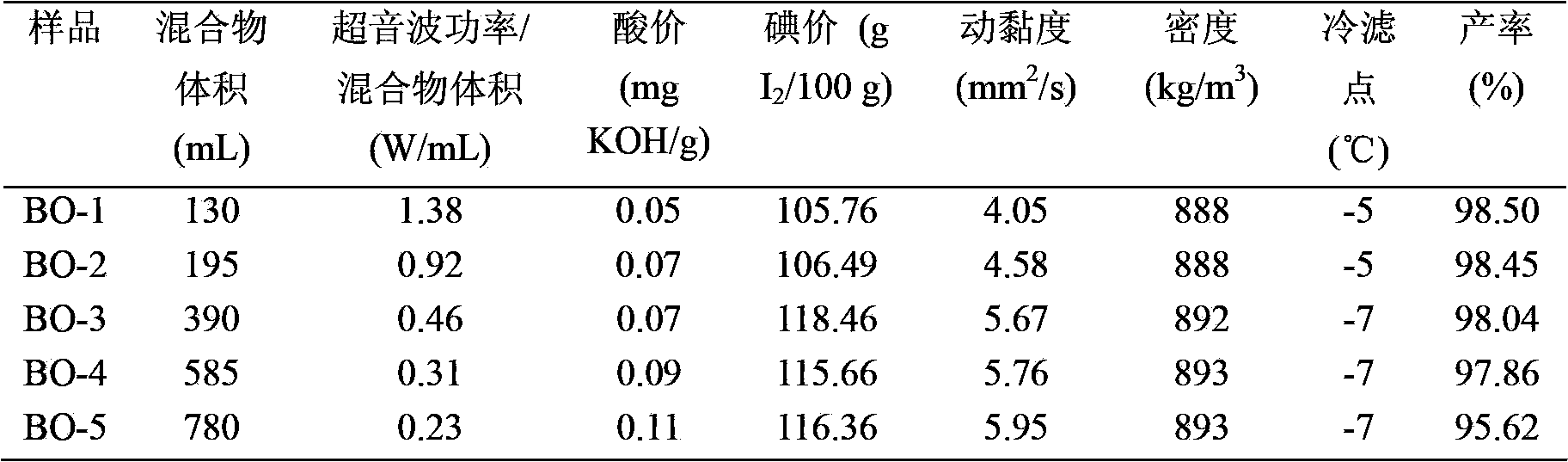

[0027] Embodiment 1. The fixed ultrasonic power is 180W

[0028] The blending ratio of the oil product in this embodiment is 60% tung oil, 30% canola oil and 10% palm oil, wherein the tung oil is extracted from the tung oil seeds produced by the tung oil tree in Miaoli County, Taiwan; the canola oil is purchased from Taiwan Flavor Co., Ltd., its main fatty acid component is oleic acid (oleic acid); palm oil is purchased from Taiwan Justice Co., Ltd., its main fatty acid component is palmitic acid (palmitic acid), and the molar ratio of methanol to oil is 6, and a mixture is formed by using potassium hydroxide (KOH) with a concentration of 2wt% as a transesterification catalyst, and then the volume of the mixture is adjusted to be between 130mL and 780mL. The mixture is placed in the reaction vessel 40, and the frequency of the ultrasonic controller 10 is set to 20 kilohertz (kHz), the mixture is vibrated ultrasonically for 5 minutes with the ultrasonic transmitter 30, and the ...

Embodiment 2

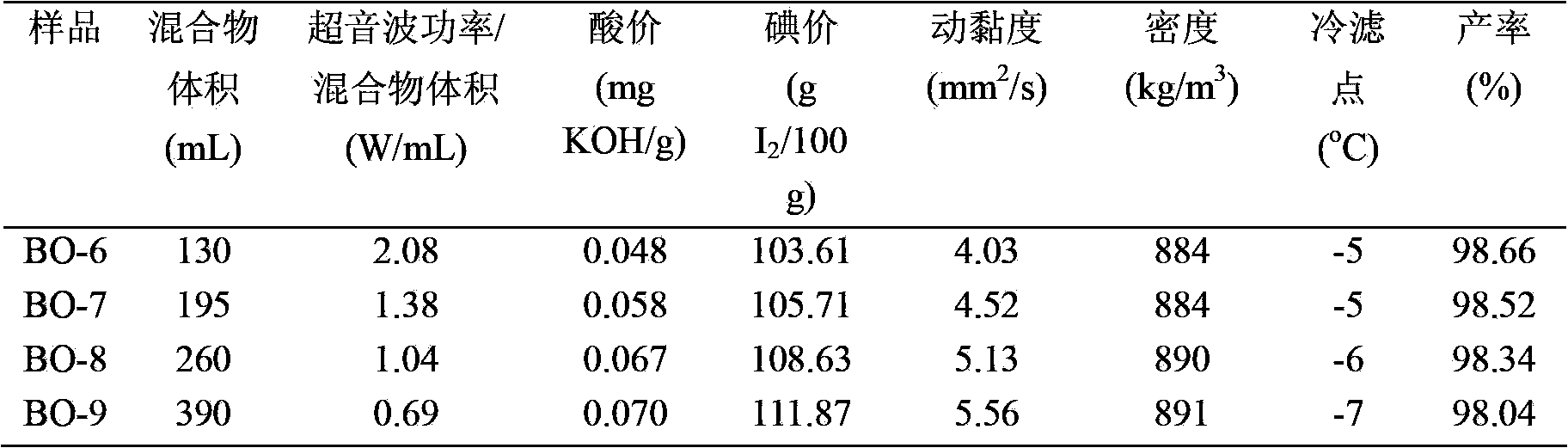

[0032] Embodiment 2. The fixed ultrasonic power is 270W

[0033] The blending ratio of the oil product of this embodiment is as described in Example 1, which is 60% tung oil, 30% canola oil and 10% palm oil, so that the molar ratio of methanol to oil product is 6, and the concentration is 2wt%. Potassium hydroxide (KOH) is used as a transesterification catalyst to form a mixture, and the volume of the mixture is adjusted to between 130mL and 390mL, then the mixture is placed in the reaction vessel 40, and the ultrasonic controller 10 The frequency of the mixture was set to 20 kHz, the mixture was oscillated by ultrasonic waves 30 for 5 minutes, and the thermometer 20 and the constant temperature water tank 50 were adjusted to make the reaction temperature 25°C.

[0034] The results are shown in Table 2. When the ultrasonic power is fixed at 270W, the acid value, iodine value and dynamic viscosity of each oil product also decrease with the decrease of the mixture volume, while ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com