Laser additive manufacturing method and equipment for metal parts

A metal parts, laser additive technology, applied in the direction of metal material coating process, coating, etc., can solve the problems of heavy load, overweight machine tool, increased manufacturing cost and difficulty coefficient, etc., to reduce the complexity of the device, spare metal powder The effect of reduced weight and high forming accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

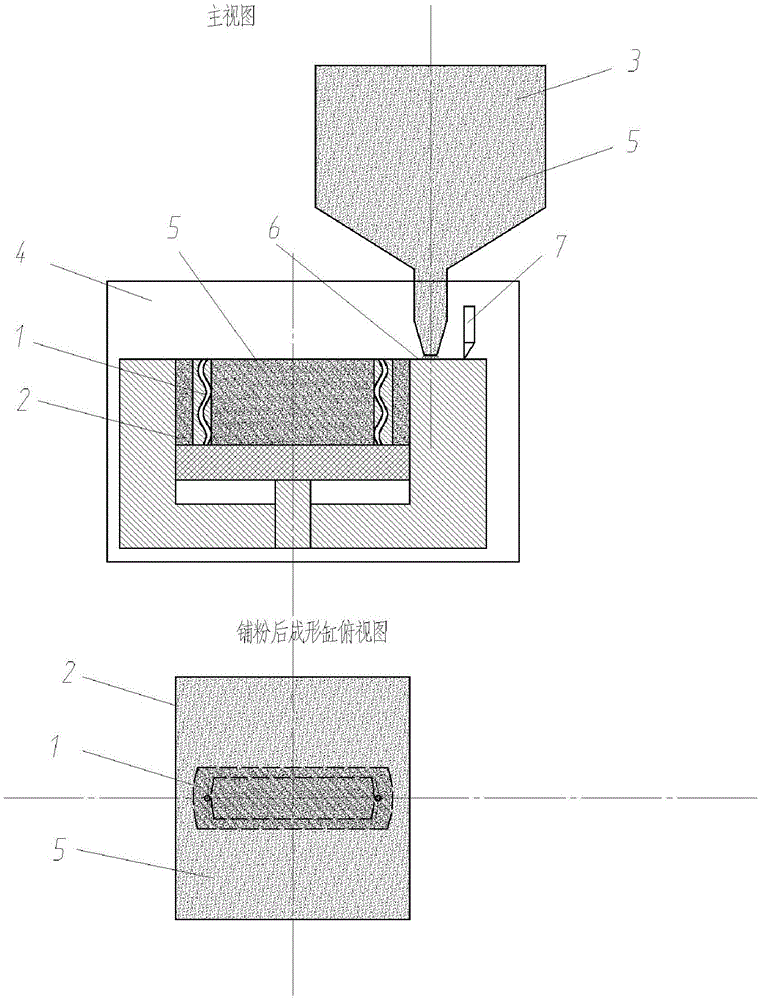

[0085] Examples 1 to 4 use Figure 4 The structure shown is realized.

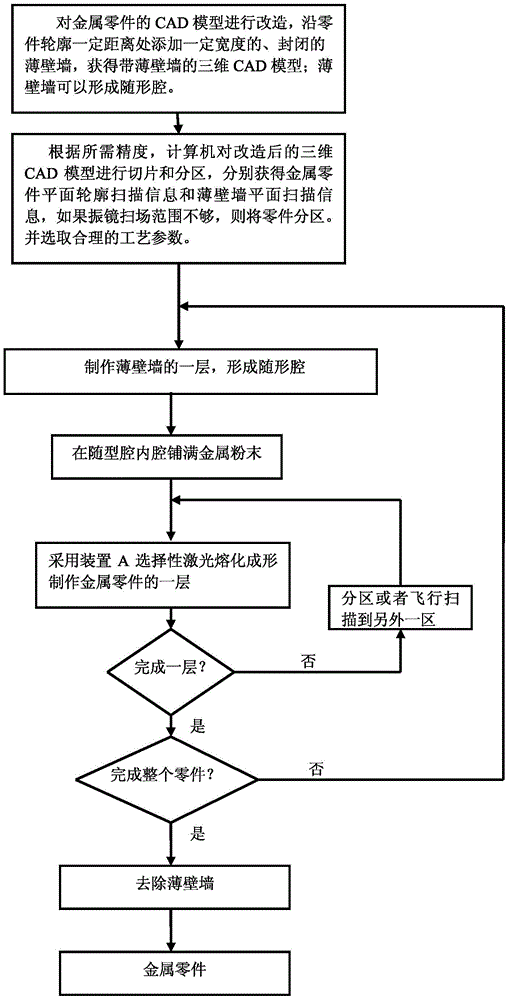

[0086] (1) Transform the CAD model of the metal part 1 to obtain the layered contour information of the metal part 1 and the thin wall 8: add a 4mm wide thin wall 8 and thin wall 8 at a place 1mm away from the periphery of the metal part contour Close to form a "conformal cylinder" 9; according to the required accuracy, use a computer to slice the transformed 3D CAD model in layers, and obtain the scanned contour information of each layer of the thin wall 8 and the metal part 1 respectively;

[0087] (2) Using LMD technology to manufacture a layer of thin wall 8: the laser is converted to the light guide system 23 through the beam converter 27, reaches the optical focusing system 22, and then focuses on the working surface to form a suitable spot, and the control system controls the machine tool to drive the laser and the optical focusing system to scan along the outline and path planning of the thin-wall...

example 2-4

[0095] The process is as in Example 1, and the process parameters are shown in Table 1 below.

example 5

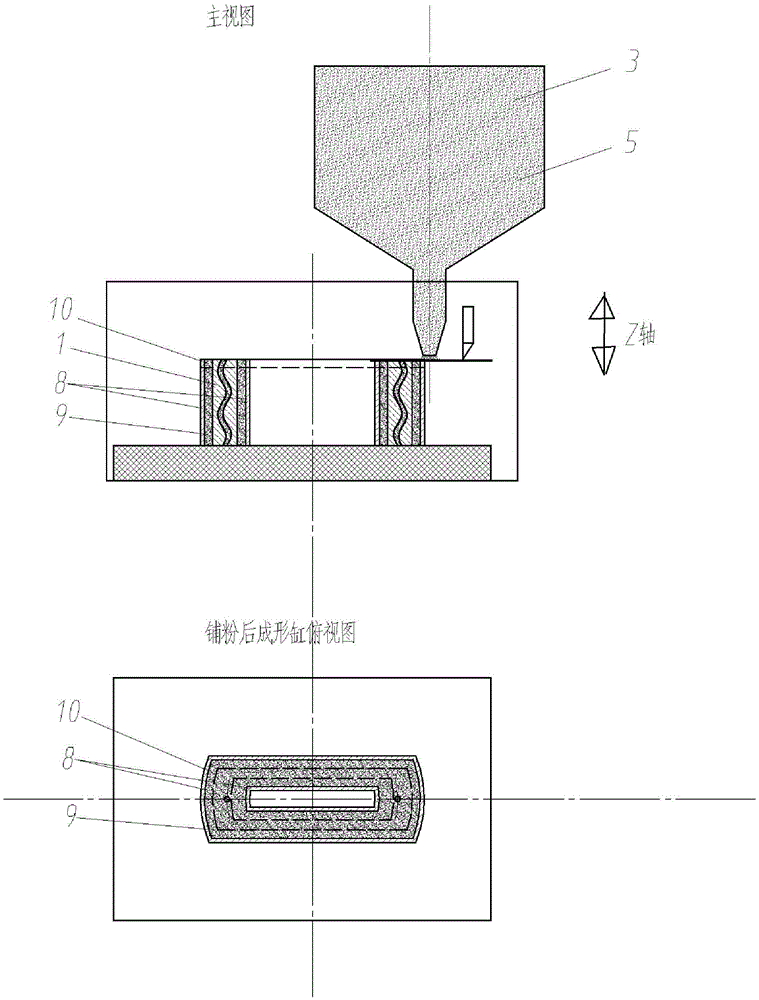

[0097] This example adopts the method for welding to prepare thin-walled wall 8, and its steps are as follows:

[0098] (1) Transform the 3D CAD model of the metal part to obtain the layered contour information of the metal part 1 and the thin wall 8 . Transform the three-dimensional CAD model of the metal part 1 in the computer control system software: add a closed outer edge (i.e. thin-walled wall 8) with a width of 1 mm at a place 25 mm away from the edge contour of the metal part 1, and the thin-walled wall 8 can be Form follow-up cylinder 9. According to the shape of the part, the conformal cylinder 9 can be a cavity that surrounds the entire part, or it can be divided into multiple cavities that can form a closed area according to the characteristics of the part; according to the required dimensional accuracy of the manufactured part, Using a computer to carry out layered slices on the modified CAD model with thin-walled walls to obtain the laser plane scanning profile ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com