Method and experimental device suitable for measuring heat conductivity coefficient of flowing high-temperature high-pressure fluid

A technology of thermal conductivity, high temperature and high pressure, applied in the field of thermal conductivity measurement of high temperature and high pressure fluid, can solve the problems of lack of experimental data on thermal conductivity of aviation kerosene, unfavorable research and application of new cooling methods, increased testing difficulty and development cost, etc., to achieve the goal of developing And the effect of short production cycle, reducing heat loss in natural convection heat exchange, and improving the measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

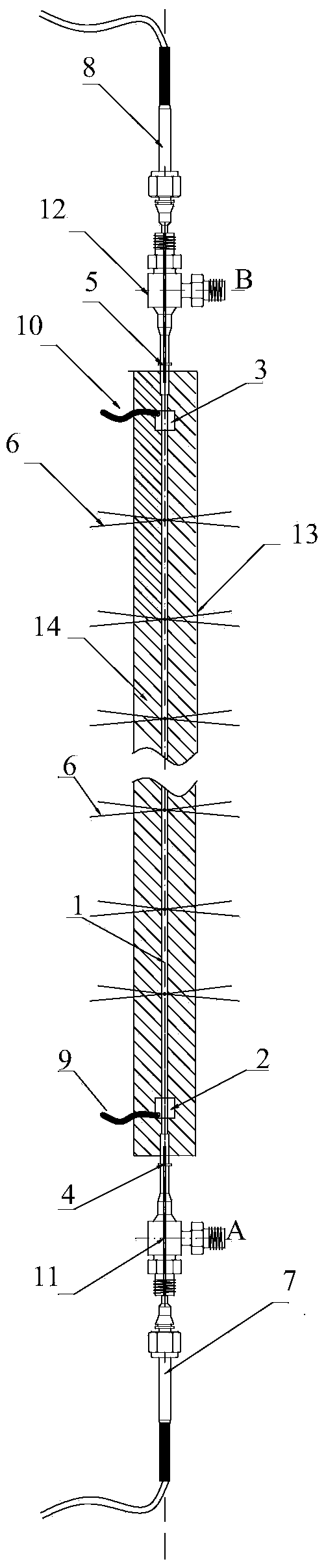

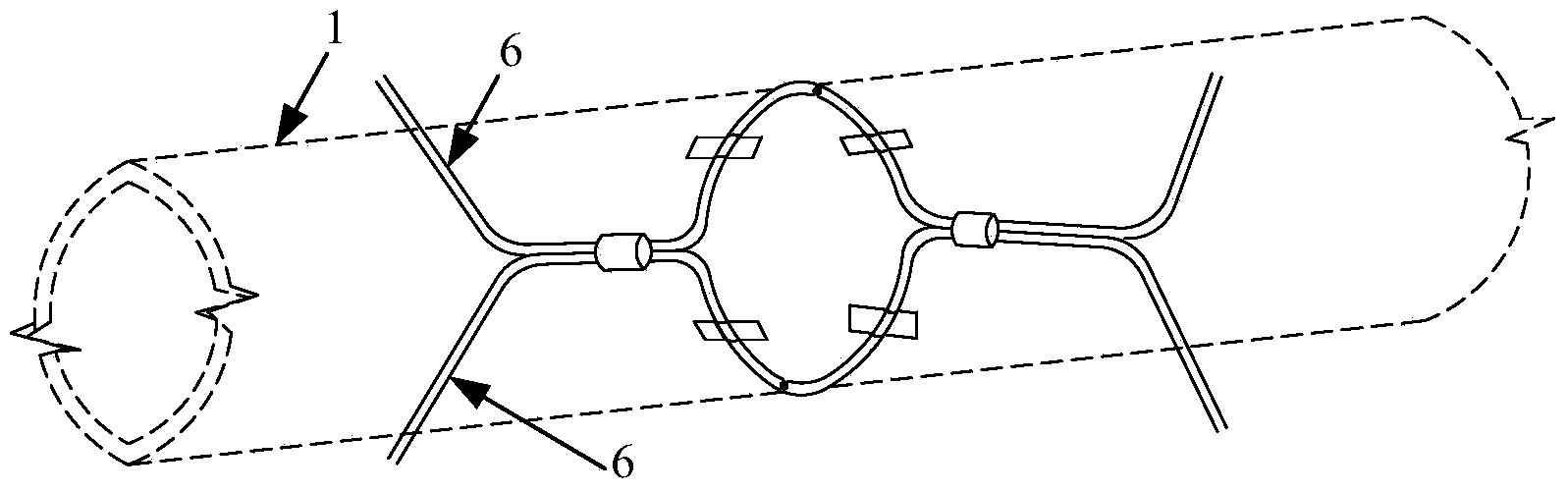

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings.

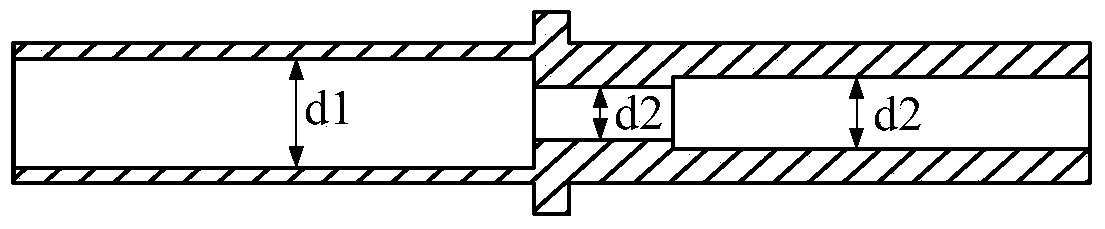

[0031] The method suitable for measuring fluid thermal conductivity provided by the present invention is based on the condition that laminar flow, constant heat flow boundary, flow and thermal boundary layer are fully developed simultaneously, and the convective heat transfer of fluid in a circular channel is mainly a diffusion process, only with The thermal conductivity of the fluid is related to the pipe diameter. Therefore, the present invention provides a method and an experimental device suitable for measuring the thermal conductivity of a flowing high-temperature and high-pressure fluid. By accurately measuring the convective heat transfer coefficient between the pipe wall and the fluid in the pipe, it can be obtained that The thermal conductivity of the fluid. The theoretical derivation process is as follows:

[0032] The momentum conservation equation of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com