Insulated wire and coil

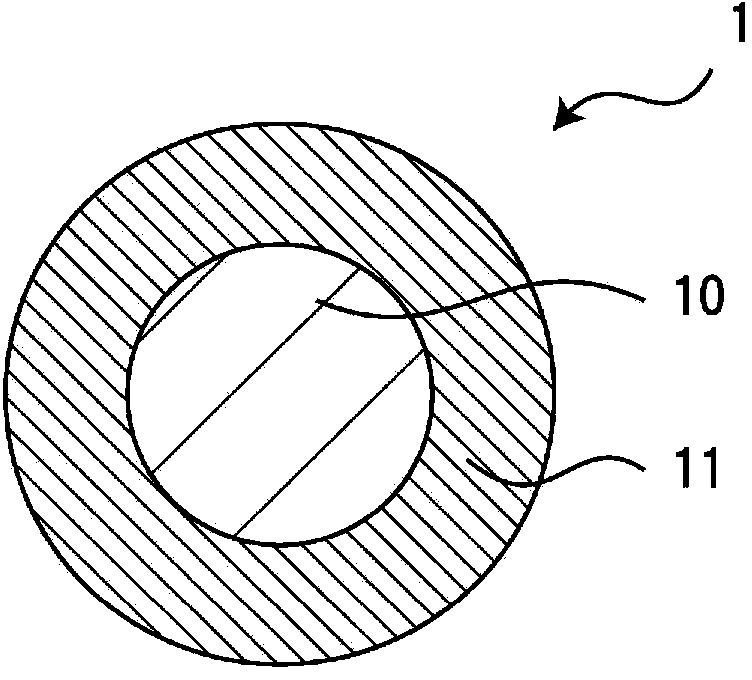

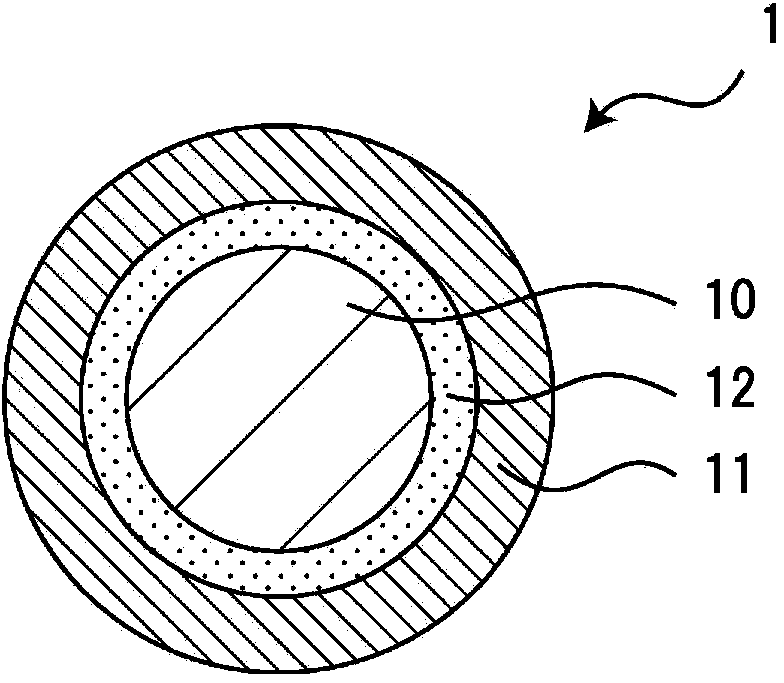

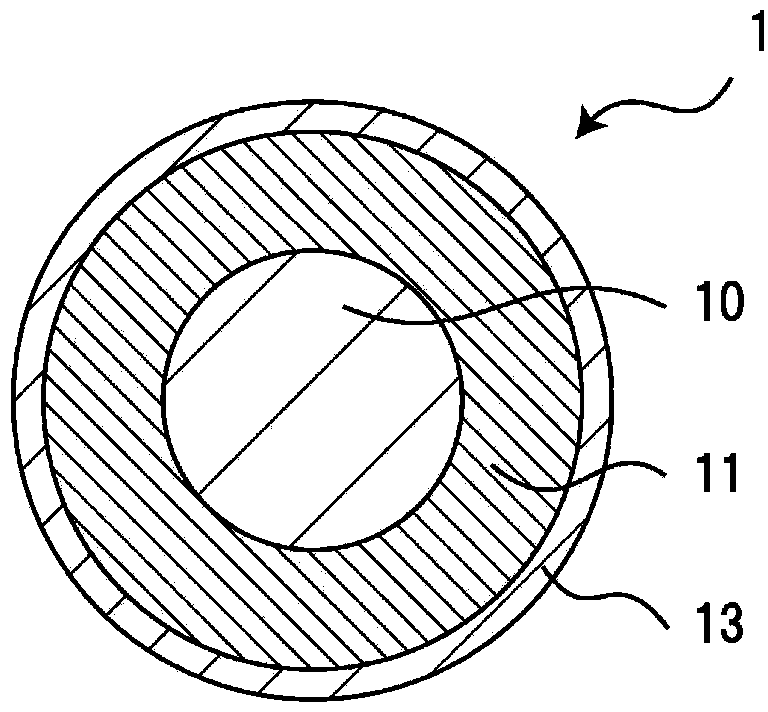

一种绝缘电线、线圈的技术,应用在绝缘电缆、绝缘体、绝缘导体等方向,能够解决绝缘不良、介质击穿、绝缘层侵蚀等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0035] One embodiment of the present invention will be described below.

[0036] First, the polyimide paint used for forming the polyimide resin constituting the insulating layer will be described.

[0038] Polyimide coatings contain polyamic acid. Polyamic acid is synthesized from carboxylic acid anhydride and diamine, and has an amide bond in the molecule. This polyamic acid is polymerized by heating to become a polyimide resin having a predetermined repeating unit.

[0039] In this embodiment, the polyimide resin which has the repeating unit A in a part of molecular structure is formed from the polyimide paint containing the polyamic acid which becomes the repeating unit A by heating. This polyimide resin has a water absorption rate of 2.8% or less after 24 hours under conditions of a temperature of 40° C. and a humidity of 95%, and therefore has a low relative dielectric constant and exhibits a high partial discharge inception voltage.

[0...

Embodiment 1)

[0107] When producing an insulated electric wire, the polyimide paint used for forming the insulating layer containing a polyimide resin was prepared by the method shown below.

[0108]

[0109] First, 437.5 g of 4,4'-diaminodiphenylether (ODA) as a diamine was dissolved in 3697.2 g of N-methyl-2-pyrrolidone (NMP) as a solvent. Next, 393.2 g of pyromellitic dianhydride (PMDA) and 93.6 g of 3,3′,4,4′-biphenyltetracarboxylic dianhydride (s-BPDA) were dissolved in NMP as a solvent. Then, the polyimide coating material containing the polyamic acid A and the polyamic acid B was prepared by synthesizing, stirring at room temperature under nitrogen atmosphere for 12 hours. In addition, in order to improve the coating workability|operativity of a polyimide paint, a solvent is added to a paint, and dilution is adjusted.

[0110] In Example 1, the molar ratio of PMDA, s-BPDA and ODA was set to 85:15:103, and the polyimide resin in which the molar ratio of repeating unit A and repeati...

Embodiment 2~5)

[0131] In Examples 2-5, as shown in Table 1, the addition amount of PMDA and s-BPDA which are carboxylic acid anhydrides was changed suitably, the polyimide coating material was prepared, and the insulated electric wire was manufactured similarly to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hygroscopic ratio | aaaaa | aaaaa |

| hygroscopic ratio | aaaaa | aaaaa |

| hygroscopic ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com