Milk thistle seed hulling and hull and kernel separating method

A technology of milk thistle and raw water, which is applied in solid separation, chemical instruments and methods, and separation of solids from solids by air flow, etc., can solve the problem of difficult separation and recovery of milk thistle shells and kernels, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

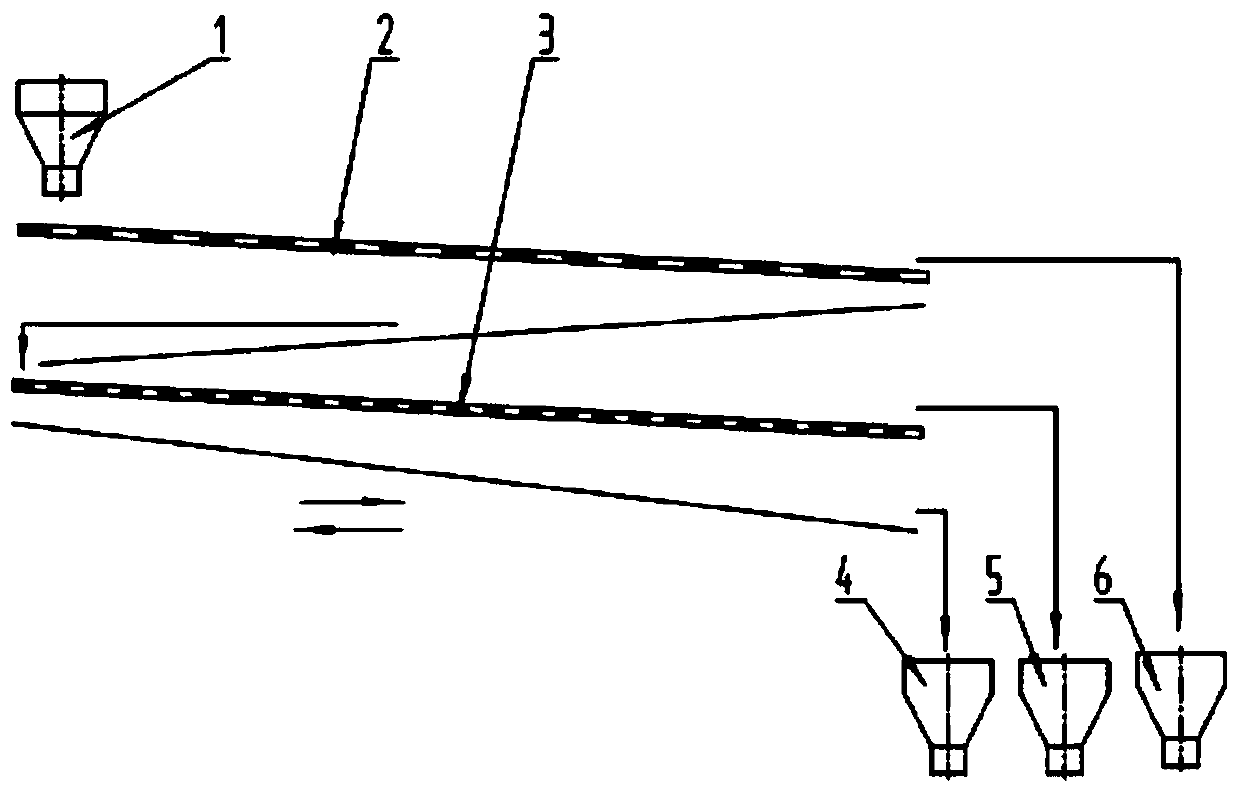

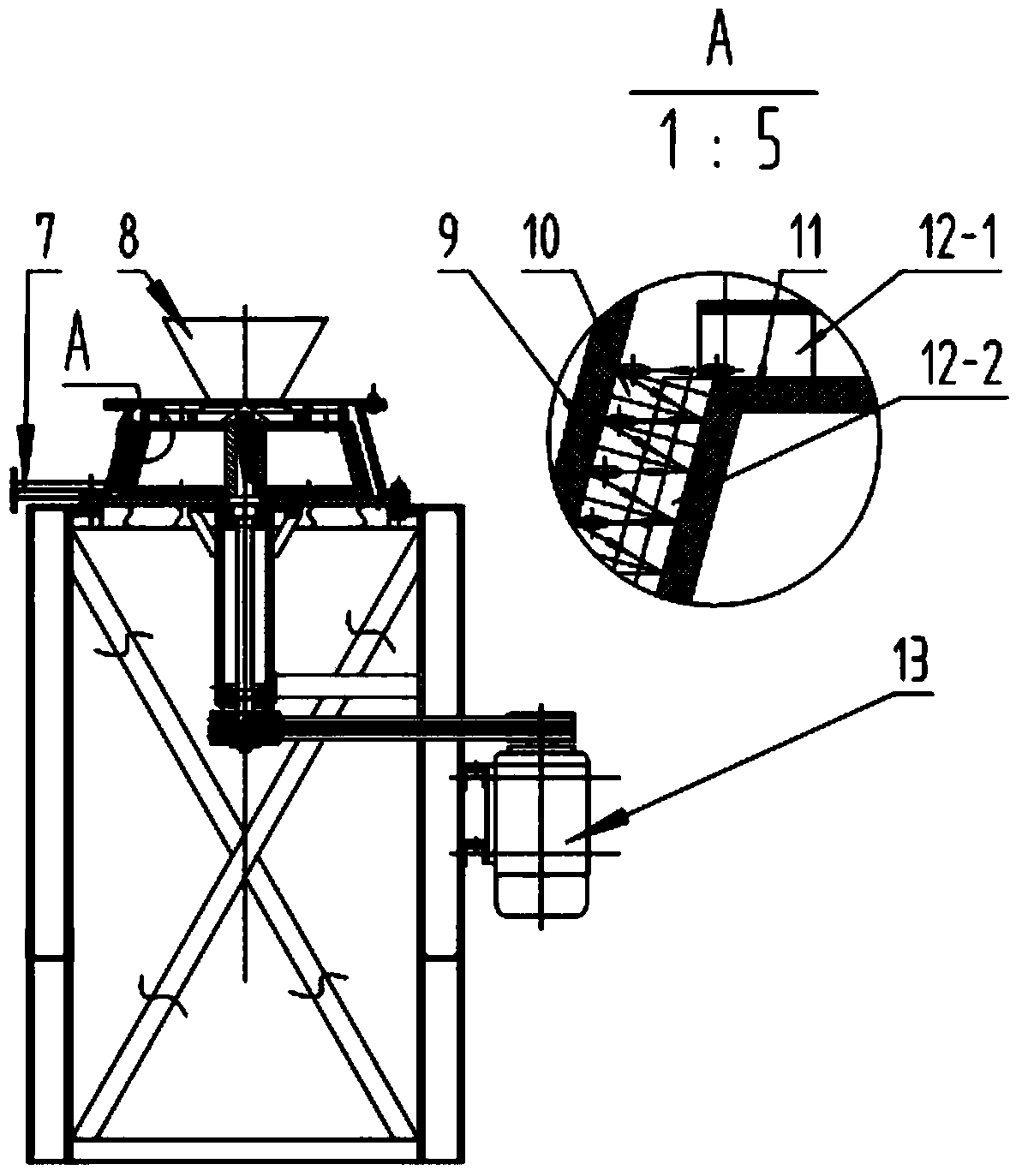

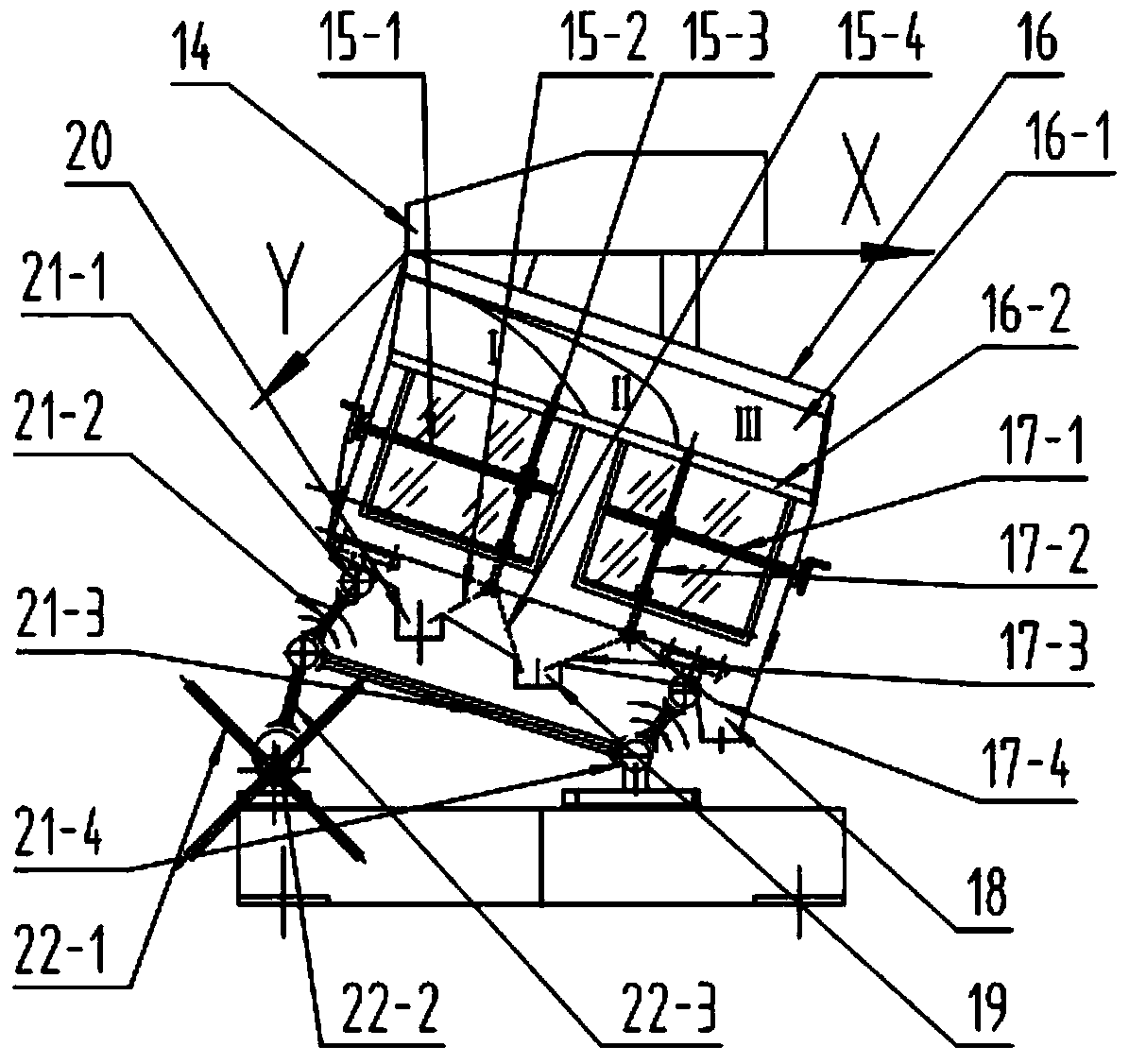

[0060] Image 6 It is the process flow diagram of milk thistle seed shelling and shell kernel separation technology embodiment 1, Figure 7 Is the process flow chart of the production line. like Figure 7 As shown, the production line main equipment of the present invention includes such as figure 1 One set of 49 cleaning sieves shown, such as figure 2 50 shelling machines are shown, such as image 3 One set of gravity screen 51 shown, such as Figure 4 Shown high-efficiency wind separator 52A and high-efficiency wind separator 52B, and as Figure 5 One set of 53 bag-pit drum separators shown; figure 1 Shown cleaning sieve 49 adopts standard equipment MMJP type grading and selection sieve, image 3 Shown gravity screen 51 adopts standard equipment MGCZ type gravity paddy separator, Figure 5 Shown bag pit type drum separator 53 adopts standard equipment Φ6 bag pit type MJXT type drum sorting machine. figure 2 The shelling machine 50 shown adopts the applicant's au...

Embodiment 2

[0069] Figure 8 It is the process flow diagram of milk thistle seed shelling and shell kernel separation technology embodiment 2, in its corresponding production line, different from embodiment 1, as Figure 4 The shown high-efficiency wind separator only needs to be used with one, and the following is described in accordance with the use of high-efficiency wind separator 52A; meanwhile, in this production line, if Figure 5 The type selection of the shown bag pit type drum concentrator 53 adopts standard equipment Φ5.5 bag pit type MJXT type drum concentrator; the selection of all the other standard equipment is the same as in embodiment 1; as figure 2 Shown dehuller 50 and as Figure 4 The high-efficiency wind separator 52A shown adopts the patented technology described in Embodiment 1. Compared with the process of Example 1, Example 2 adjusted the sequence of each process. follow below Figure 8 Shown process sequence, emphatically narrates the place that is different f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com