Sn-Zn-Bi-base lead-free solder alloy for soft soldering of aluminum and copper

A lead-free solder and soldering technology, applied in welding/cutting media/materials, welding media, welding equipment, etc., can solve the problems of high melting point, poor wettability of aluminum substrates, and poor mechanical properties of brazing joints. Achieve the effect of increasing the degree of dissolution, improving the oxidation resistance, and reducing the effect of oxidation and ablation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

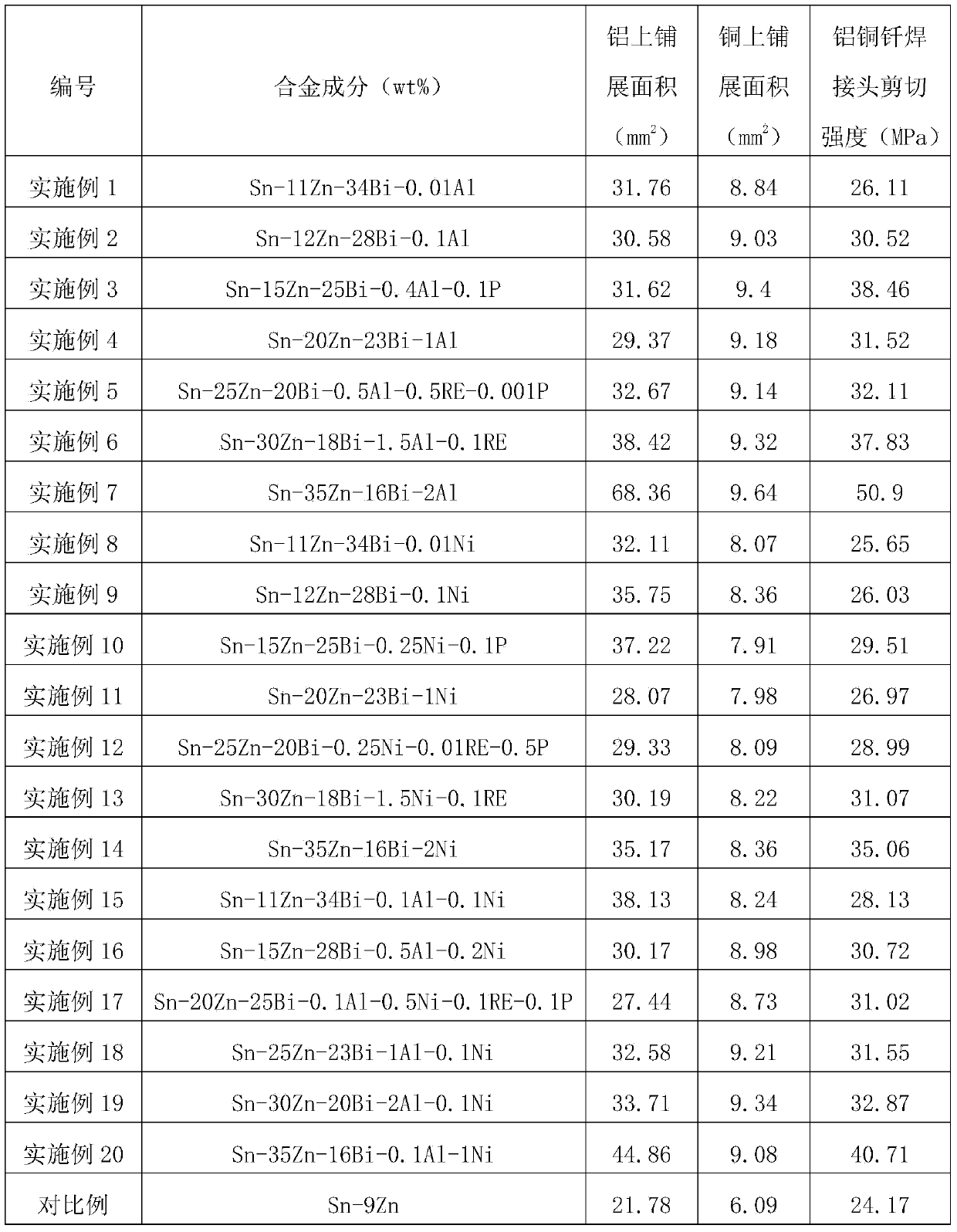

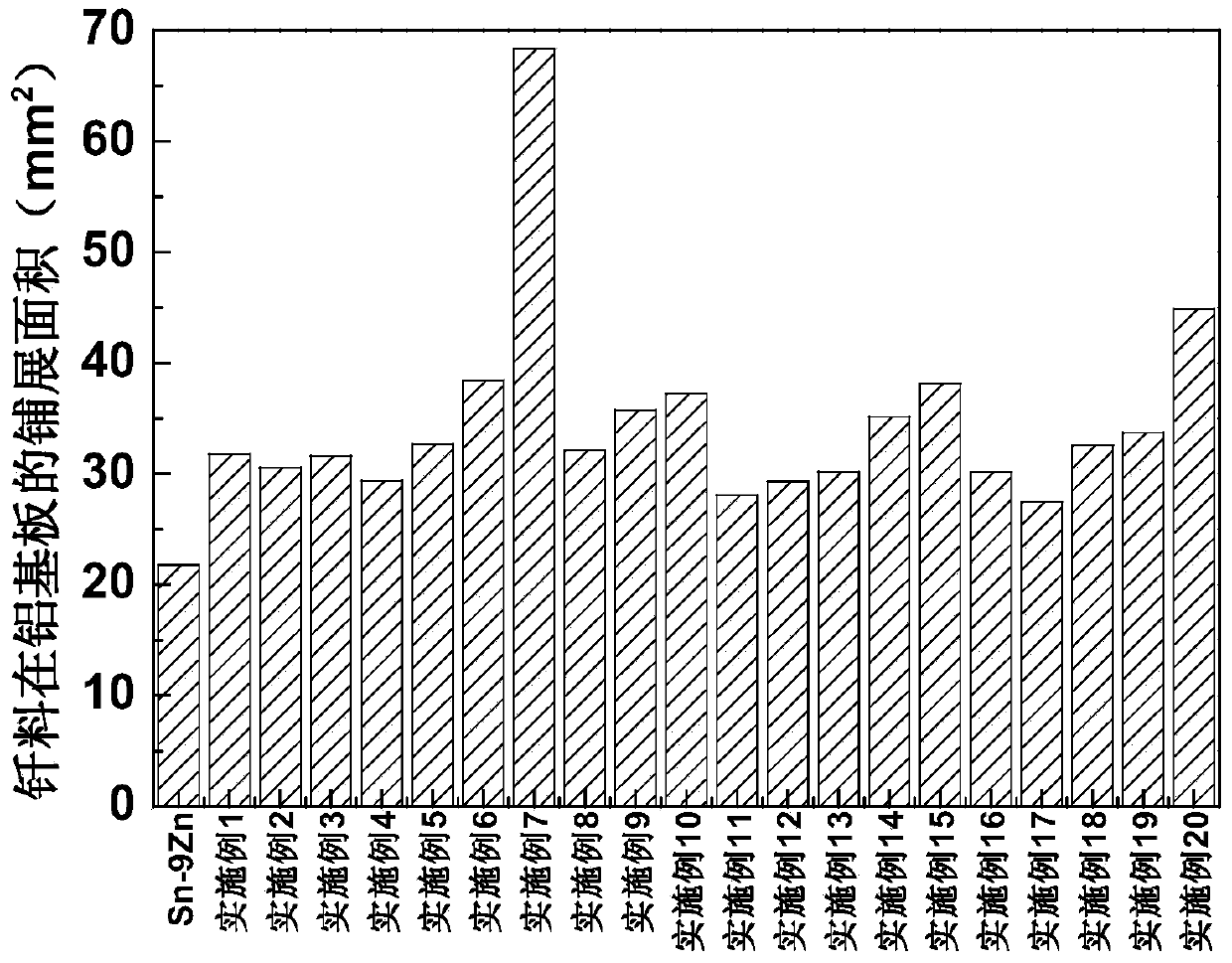

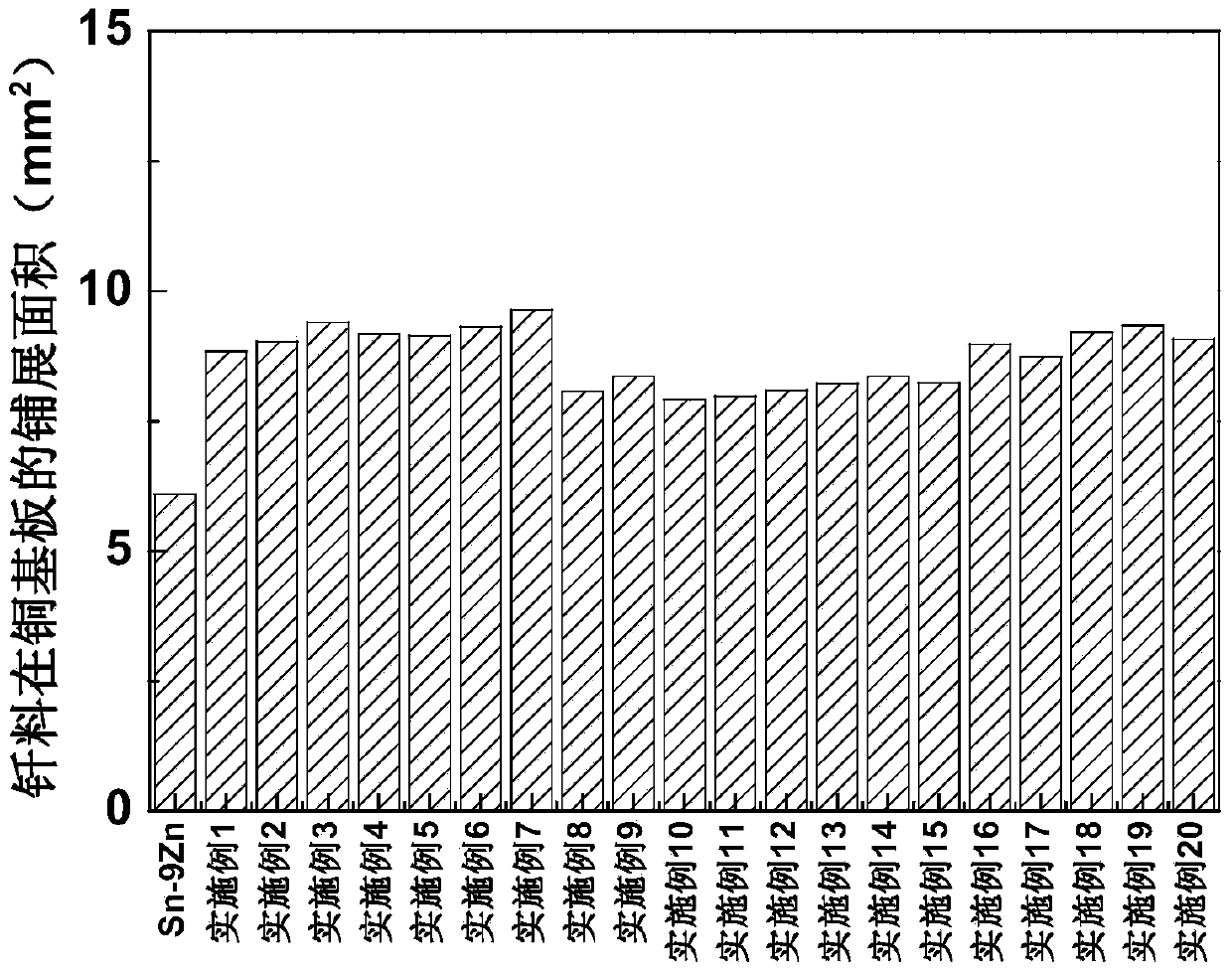

Examples

Embodiment 1

[0025] Each component is calculated by weight percentage: Zn11%, Bi34%, Al0.01%, and the balance is Sn.

[0026] The preparation method of solder is as follows:

[0027] (1) The preparation of the lead-free solder alloy is to use the metal Sn with a purity of 99.99%, the metal Zn with a purity of 99.99%, the metal Bi with a purity of 99.99%, the metal Al with a purity of 99.99%, and the metal with a purity of 99.99%. Ni, proportioning the components of the solder alloy by weight percentage, a total of 100g, is placed in the high temperature resistant tube;

[0028] (2) Use a hydrogen flame to melt and seal one end of the high-temperature resistant tube, melt the other end into a thin mouth and use a vacuum pump to vacuumize, and after the air in the pipe is exhausted, melt and seal the thin mouth;

[0029] (3) Put the high-temperature-resistant tube in a resistance furnace, heat it to 650°C and melt it. After all the components are melted, keep it warm for 2-3 hours to homoge...

Embodiment 2

[0031] Each component is calculated by weight percentage: Zn12%, Bi28%, Al0.1%, and the balance is Sn. Alloy preparation method is the same as embodiment 1.

Embodiment 3

[0033] Each component by weight percentage is: Zn 15%, Bi 25%, Al 0.4%, P 0.1%, and the balance is Sn. Alloy preparation method is the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com