Preparation method of 1,4-naphthalenedicarboxylic acid

A technology of naphthalene dicarboxylic acid and naphthoic acid, which is applied in the direction of carboxylate preparation, organic compound preparation, chemical instruments and methods, etc., can solve the problems of expensive raw materials, large energy consumption, environmental pollution, etc., and achieve abundant resources, Effects of reducing discards and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

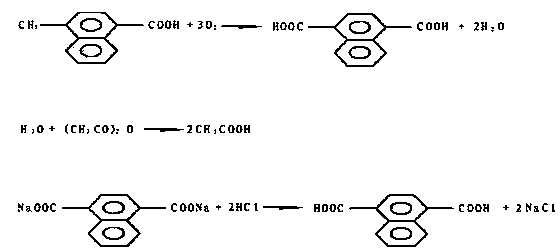

Method used

Image

Examples

Embodiment 1

[0017] The 1-methyl-4-naphthoic acid that 200kg concentration is 98% is dissolved in 300kg glacial acetic acid, and in mixed solution, add the cobalt acetate that mass ratio is 1:50, the manganese acetate that mass ratio is 1:50, mass ratio 1:50 sodium acetate, the amount of cobalt acetate, manganese acetate, and sodium acetate is based on the mass of 1-methyl-4-naphthoic acid, then start to heat up to 70°C until the materials are completely dissolved, and evenly introduce air , Sampling and analysis in the middle, the content of 1-methyl-4-naphthoic acid is less than 0.5% is the reaction end point, and the crude product of 1,4-naphthalene dicarboxylic acid with a content of more than 96% is obtained by cooling and filtration. Add acetic anhydride to the mother liquor to remove water, then add new 1-methyl-4-naphthoic acid according to the normal batch reaction (the amount added is the same as the batch), then add cobalt acetate, manganese acetate, acetic acid Sodium reaction,...

Embodiment 2

[0019] The 1-methyl-4-naphthoic acid that 100kg concentration is 98% is dissolved in the glacial acetic acid of 1500kg, in the mixed liquor, add the cobalt acetate that mass ratio is 1:40, the manganese acetate that mass ratio is 1:40, the mass ratio 1:40 sodium acetate, the amount of cobalt acetate, manganese acetate, and sodium acetate is based on the quality of 1-methyl-4-naphthoic acid, then start to heat up to 90 ° C until the materials are completely dissolved, and evenly introduce air , Sampling and analysis in the middle, the content of 1-methyl-4-naphthoic acid is less than 0.5% is the reaction end point, and the crude product of 1,4-naphthalene dicarboxylic acid with a content of more than 96% is obtained by cooling and filtration. Add acetic anhydride to the mother liquor to remove water, then add new 1-methyl-4-naphthoic acid according to the normal batch reaction (the amount added is the same as the batch), then add cobalt acetate, manganese acetate, acetic acid S...

Embodiment 3

[0021] The 1-methyl-4-naphthoic acid that 300kg concentration is 98% is dissolved in 4500kg glacial acetic acid, add the cobalt acetate that mass ratio is 1:30, the manganese acetate that mass ratio is 1:30, mass ratio 1:30 sodium acetate, the amount of cobalt acetate, manganese acetate, and sodium acetate is based on the quality of 1-methyl-4-naphthoic acid. Start to heat up to 78°C until the materials are completely dissolved, and then evenly pass in Air, midway sampling and analysis, 1-methyl-4-naphthoic acid content less than 0.5% is the reaction end point, cooling and filtering to obtain 1,4-naphthalene dicarboxylic acid crude product with content greater than 96%. Add acetic anhydride to the mother liquor to remove water, then add new 1-methyl-4-naphthoic acid according to the normal batch reaction (the amount added is the same as the batch), then add cobalt acetate, manganese acetate, acetic acid Sodium reaction, the amount added is 5% of the batch feed amount; 1,4-naph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com