Purple potato starch edible film and preparation method thereof

A technology of purple potato starch and edible film, applied in the direction of sustainable manufacturing/processing, climate sustainability, sustainable packaging industry, etc., can solve the problems of poor tensile strength and transparency, and achieve low cost, no pollution, Good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

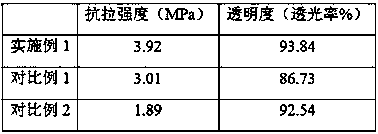

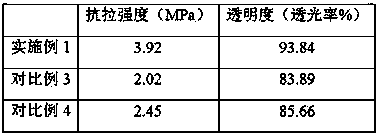

Examples

Embodiment 1

[0033] (1) Starch preparation: Dissolve 0.4g xanthan gum in 80mL distilled water, stir for 15min, then add 39.6g purple sweet potato starch to the xanthan gum solution, stir for 20min to make it evenly mixed, and adjust the pH value of the mixture to 6 ;Pour the mixed powder into a flat plate and dry it in an oven at 45°C for 13 hours (moisture content below 10%), grind and pulverize it through a 100-mesh sieve, and then place the mixed powder in an oven at 130°C for 3 hours.

[0034] (2) Mixing of raw materials: Take 3.99g of dry heat-denatured purple potato starch, dissolve it into starch milk with 100mL of distilled water, add 1.52g of glycerin, heat and stir in a water bath at 95°C for 10min, then add 0.6g of sodium alginate, and heat and stir again 20min to complete gelatinization.

[0035] (3) Degassing: Put the membrane solution in a water bath at 50°C for 10 minutes to defoam.

[0036] (4) Flow extension: Weigh 35mL of membrane liquid at one time and pour it onto a po...

Embodiment 2

[0039] (1) Starch preparation: Dissolve 0.2g xanthan gum in 80mL distilled water, stir for 15min, then add 39.8g purple potato starch to the xanthan gum solution, stir for 20min to mix well, adjust the pH value of the mixture to 8 ;Pour the mixed powder into a flat plate and dry it in an oven at 45°C for 13 hours (moisture content below 10%), grind and pulverize it through a 100-mesh sieve, and then place the mixed powder in an oven at 120°C for 4 hours.

[0040] (2) Mixing of raw materials: Take 4.21g of dry heat denatured purple potato starch, dissolve it into starch milk with 100mL of distilled water, add 1.54g of glycerin, heat and stir in a water bath at 95°C for 10min, then add 0.45g of sodium alginate, and heat and stir again 20min to complete gelatinization.

[0041] (3) Degassing: Put the membrane solution in a water bath at 50°C for 10 minutes to defoam.

[0042] (4) Flow extension: Weigh 35mL of membrane liquid at one time and pour it onto a polyethylene plate for ...

Embodiment 3

[0045] (1) Starch preparation: Dissolve 0.6g xanthan gum in 80mL distilled water, stir for 15min, then add 39.4g purple potato starch into the xanthan gum solution, stir for 20min to mix well, adjust the pH value of the mixture to 6 ;Pour the mixed powder into a flat plate and dry it in an oven at 45°C for 13 hours (moisture content below 10%), grind and pulverize it through a 100-mesh sieve, and then place the mixed powder in an oven at 120°C for 3 hours.

[0046] (2) Mixing of raw materials: Take 3.50g of dry heat-denatured purple potato starch, dissolve it into starch milk with 100mL of distilled water, add 1.52g of glycerin, heat and stir in a water bath at 95°C for 10min, then add 0.75g of sodium alginate, and heat and stir again 20min to complete gelatinization.

[0047] (3) Degassing: Put the membrane solution in a water bath at 50°C for 10 minutes to defoam.

[0048] (4) Flow extension: Weigh 35mL of membrane liquid at one time and pour it onto a polyethylene plate fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com