High performance calcium aluminate oil well cement

An oil well cement and calcium aluminate technology, applied in the field of well cement, can solve the problems of poor salt resistance and acid resistance, increased permeability, etc., and achieve stable mechanical properties, strong salt and acid resistance, and good rheology. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

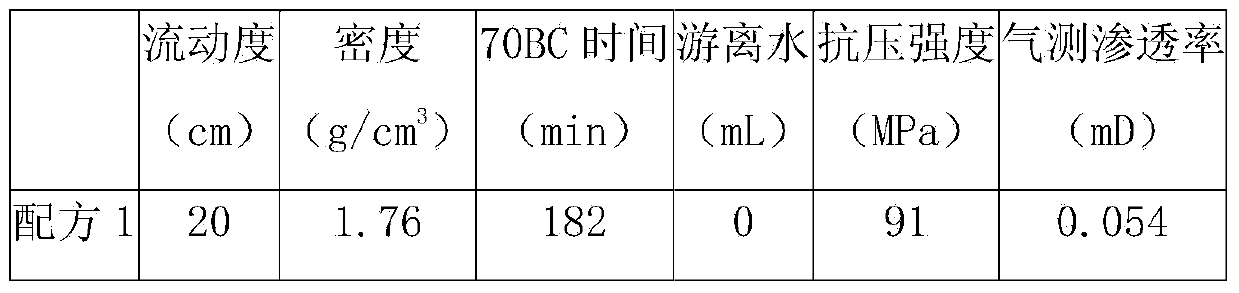

Embodiment 1

[0023] High temperature basic performance evaluation of calcium aluminate cement

[0024] The indoor experiment method of cement slurry is as follows:

[0025] First weigh each component, then put it into a clean glass container and mix it by hand; put the mixed solid phase into a high-speed blender, add an appropriate amount of water and stir, stir at 4000rpm for 25 seconds, then change to 12000rpm and stir for 35 seconds. Measure the basic properties of grout. The prepared cement slurry was poured into cement stone making molds and cured for 7 days at 100°C and 35MPa, and the compressive strength of cement stone was measured. The formula of calcium aluminate used in the experiment is as follows:

[0026] Formula 1: 500g calcium aluminate cement + 300mL water + 150g 60 mesh silica fume + 20g microsilica fume + 5gHPAM + 3.0g GH-9 high temperature retarder + 4g G33S high temperature fluid loss reducer.

[0027] Formula 2: 500g calcium aluminate cement + 350mL water + 150g 60...

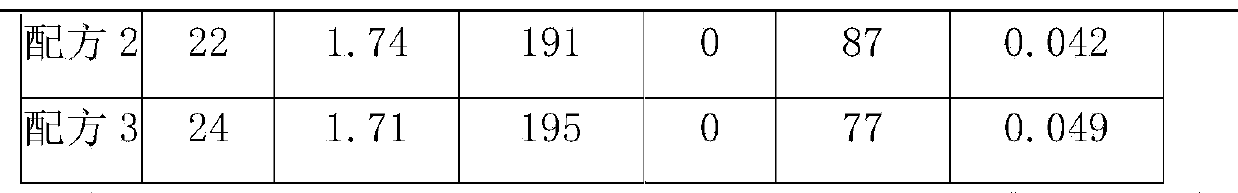

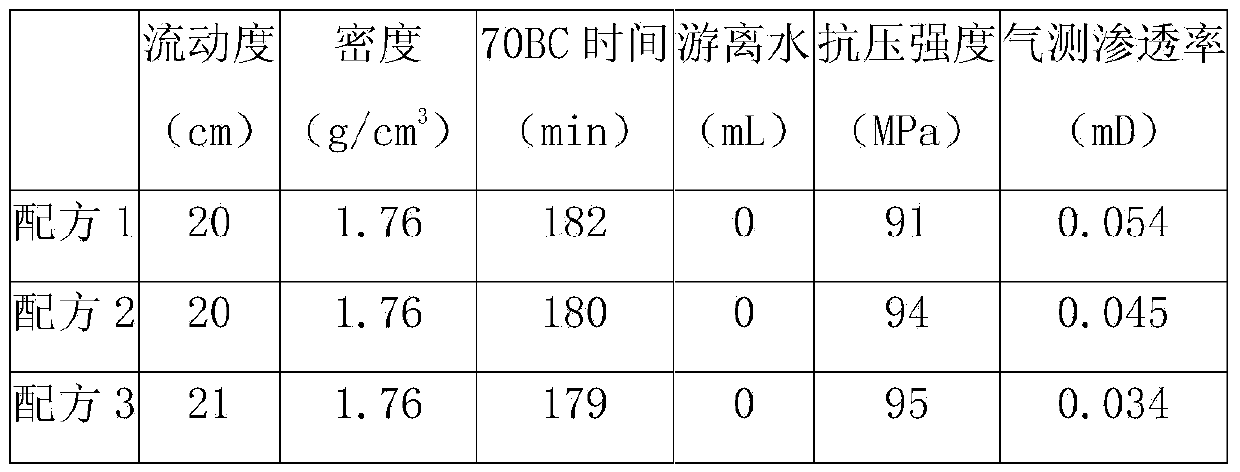

Embodiment 2

[0035] Weigh each component, then put it into a clean glass container and mix it by hand; put the mixed solid phase into a high-speed mixer, add an appropriate amount of water and stir, stir at 4000rpm for 25s, then change to 12000rpm and stir for 35 seconds. Measure the basic properties of grout. The prepared cement slurry was poured into cement stone making molds and cured for 7 days at 150°C and 35MPa, and the compressive strength of cement stone was measured. The formula of calcium aluminate used in the experiment is as follows:

[0036] Formula 1: 500g calcium aluminate cement + 300mL water + 150g 60 mesh silica fume + 20g microsilica fume + 5gHPAM + 3.0g GH-9 high temperature retarder + 4g G33S high temperature fluid loss reducer.

[0037] Formula 2: 500g calcium aluminate cement + 300mL water + 150g 100 mesh silica fume + 20g microsilica fume + 5gHPAM + 3.0g GH-9 high temperature retarder + 4g G33S high temperature fluid loss reducer.

[0038] Formula 3: 500g calcium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com