Method for concentrating, stabilizing and separating liquid enzyme

A liquid enzyme and stabilization technology, which is applied in the field of separation, concentration and stabilization of liquid enzyme preparations, and can solve the problems of enzyme inactivation and low content of encapsulated biological enzymes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The nonionic surfactant EO 11 PO 69 EO 11 (HLB value 6.0) 0.9g was dissolved in 50g water, then 1g of liquid protease preparation was mixed with it, the mixture was added dropwise to 0.8g α-cyclodextrin, and then 2.4g 1,2-propanediol stabilizer was added and mixed well.

[0044]The above-mentioned uniformly mixed liquid was sealed and stirred at 20°C for 20 hours. The enzyme activity of the liquid protease preparation was determined according to the national standard GB / T23527-2009, as shown in the table below.

[0045]

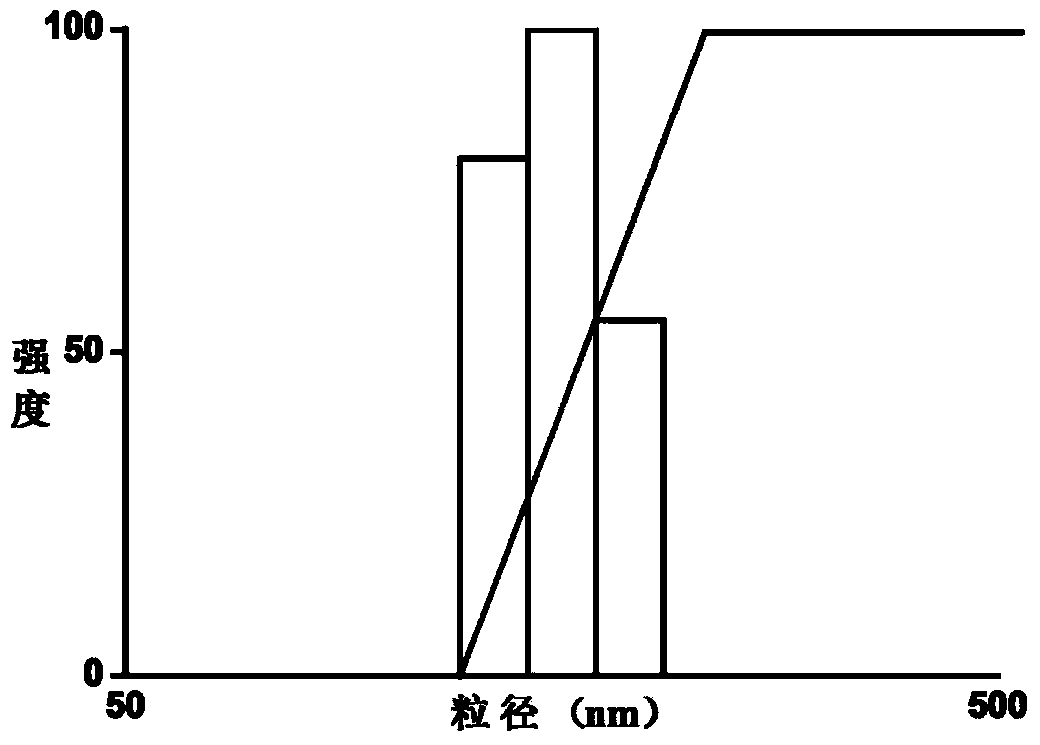

[0046] Dynamic Light Scattering (DLS) was used to test the nanostructure of the sample. Particle size distribution of supramolecular microspheres (see figure 1 ), the average size of the encapsulated enzyme particles is about 270nm.

Embodiment 2

[0048] The nonionic surfactant EO 133 PO 50 EO 133 (HLB value 26.0) 9g was dissolved in 50g ethanol, then 38g liquid lipase preparation was mixed with it, the mixture was added dropwise to 1.5g β-cyclodextrin, and then 0.5g 1,3-propanediol stabilizer was added and mixed well.

[0049] The above-mentioned uniformly mixed liquid was sealed and stirred at 20°C for 22 hours. The enzyme activity of the liquid lipase preparation was determined according to the national standard GB / T23527-2009, as shown in the table below.

[0050]

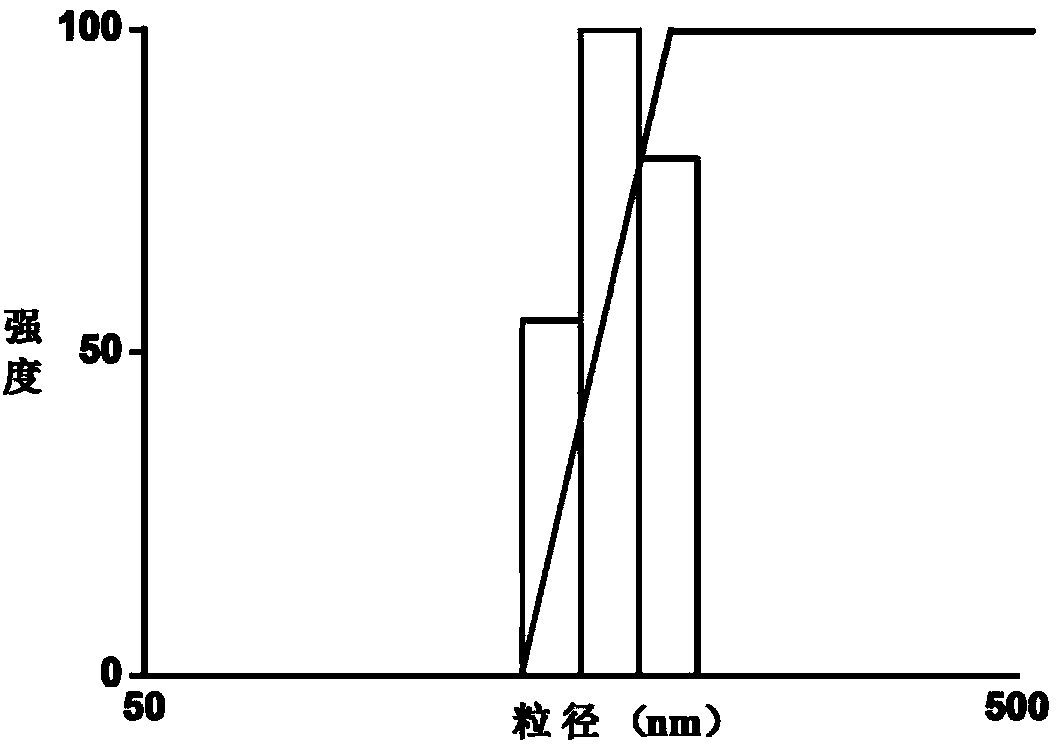

[0051] Dynamic Light Scattering (DLS) was used to test the nanostructure of samples. Particle size distribution of supramolecular microspheres (see figure 2 ), the average size of the encapsulated enzyme particles is about 298nm.

Embodiment 3

[0053] The nonionic surfactant EO 3 PO 43 EO 3 (HLB value 6.0) 20g is dissolved in 100g of acetone, then take 18g of liquid hemicellulase preparation and mix with it, the mixture is added dropwise to 10g of small cyclopan, then add 0.55g of 1,2-butanediol stabilizer and mix well .

[0054] The above-mentioned uniformly mixed liquid was sealed and stirred at 30°C for 24 hours, and the enzyme activity of the liquid hemicellulase preparation was determined according to the national standard GB / T23527-2009, as shown in the table below.

[0055]

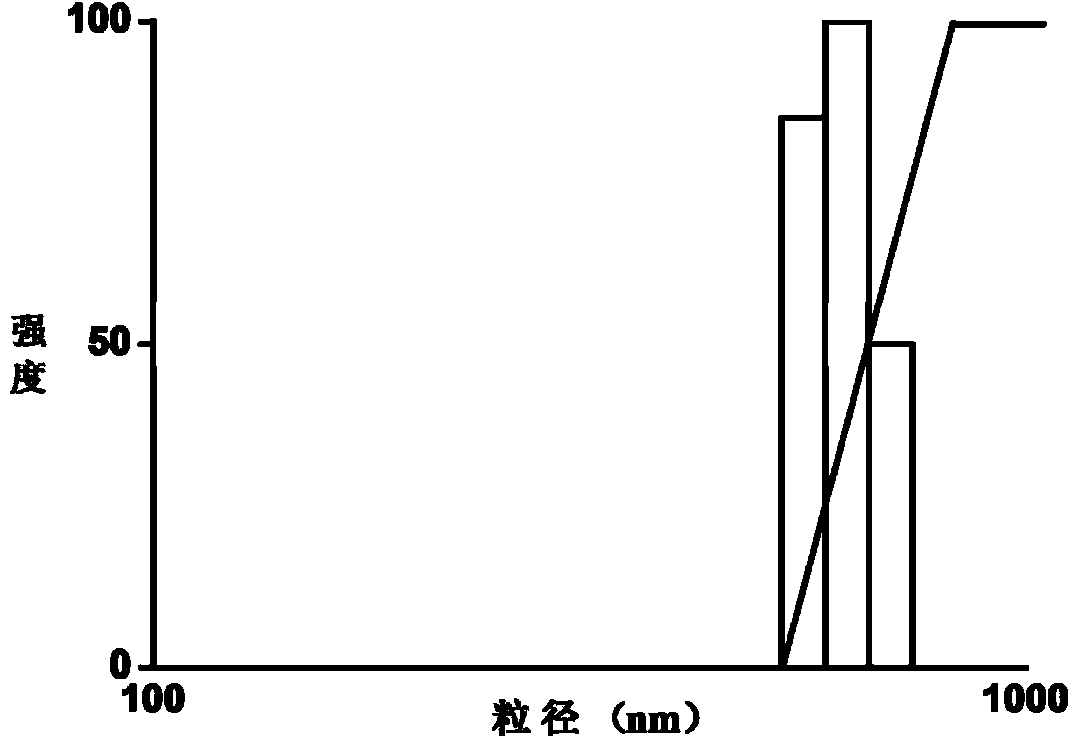

[0056] Dynamic Light Scattering (DLS) was used to test the nanostructure of samples. The particle size distribution of supramolecular microspheres is shown in the figure below (see image 3 ), the average size of the encapsulated enzyme particles is about 806nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com