Surface steel nail type steel sleeve packed optical fiber raster strain sensor and method the same

A strain sensor and fiber grating technology, which is applied in the field of road intelligent monitoring, can solve the problem that fiber grating sensors cannot co-deform with asphalt concrete, and achieve the effects of excellent mechanical properties, long service period and low shrinkage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

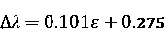

[0032] Embodiment 1, a surface steel nail type steel sleeve packaged fiber grating strain sensor and its preparation method.

[0033] Make a sensor for the SMA13 asphalt mix type. like figure 1 , figure 2 , image 3 , there is a bare fiber 1, the pigtail part of the bare fiber 1 except the grating segment is sheathed in the white sleeve 2, the white sleeve 2 is sheathed into the armored cable 3, and the preliminarily encapsulated optical fiber is sheathed in the steel sleeve 4, the steel sleeve 4. Steel nails 5 are welded on the surface, and end expansion heads 6 are provided at both ends. The gap between the armored cable 2 and the steel sleeve 4 is injected with an epoxy resin adhesive 7 with a syringe 12, and a plug 8 is used at both ends of the steel sleeve 4. seal.

[0034] In the process of sensor packaging, when pouring epoxy resin adhesive, an iron frame 9 is needed. The sensor is fixed by the sensor fixing clip 10 on the iron frame 9, and the optical fiber of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com