Method for preparing denitrified catalyst through cobalt-manganese double-exchange molecular sieve

A technology of denitration catalyst and molecular sieve, which is applied in the preparation and application field of denitration catalyst, can solve the problems such as the catalytic efficiency needs to be improved, and achieve the effects of controlling production cost, high catalytic activity and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

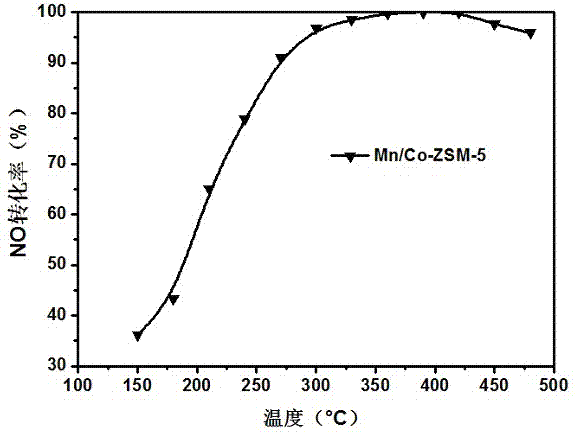

Embodiment 1

[0024] Cobalt acetate and manganese acetate solutions with concentrations of 0.05 mol / L and 0.1 mol / L were prepared respectively as cobalt and manganese ion exchange liquids for later use. Take H-ZSM-5 molecular sieve, add deionized water with a mass ratio of 1:25 to molecular sieve, at 70 o C stirred and activated for 0.5 h, heated to 150 o C, and at this temperature, slowly add cobalt ion exchange liquid with a mass ratio of 0.8:1 to molecular sieves, keep at this temperature for 2 h, and then at 70 o C aging for 24 h, filtered and washed with deionized water, at 90 o C dried overnight. Mix the product and deionized water evenly at a mass ratio of 1:25, and raise the temperature to 150 o C, and at this temperature, slowly add manganese ion exchange liquid with a mass ratio of 1:1 to the step product for ion exchange for 2 h, and then at 70 o C aging for 24 h, filtered and washed with deionized water, at 90 o C dried overnight. The product was placed in a tube furnace f...

Embodiment 2

[0027] Cobalt acetate solution and 0.05 mol / L manganese acetate solution with concentration of 0.025 mol / L and manganese acetate solution respectively were prepared as cobalt and manganese ion exchange liquids for use. Take Na-ZSM-5 molecular sieve, add deionized water with a mass ratio of 1:10 to molecular sieve, at 60 o C stirred and activated for 0.5 h, heated to 140 o C, and at this temperature, slowly add cobalt ion exchange liquid with a mass ratio of 0.2:1 to molecular sieve, keep at this temperature for 2 h, and then at 60 o C aging for 24 h, filtered and washed with deionized water, at 90 o C dried overnight. Mix the product and deionized water evenly at a mass ratio of 1:10, and raise the temperature to 140 o C, and at this temperature, slowly add manganese ion exchange solution with a mass ratio of 0.5:1 to the product for ion exchange for 1 h, and then at 60 o C aging for 24 h, filtered and washed with deionized water, at 90 o C dried overnight. The product w...

Embodiment 3

[0030] Cobalt chloride solution with a concentration of 0.025 mol / L and manganese chloride solution with a concentration of 0.05 mol / L were respectively prepared as cobalt and manganese ion exchange liquids for use. Take SAPO-34 molecular sieve, add deionized water with a mass ratio of 1:15 to molecular sieve, at 70 o C stirred and activated for 0.5 h, heated to 150 o C, and at this temperature, slowly add cobalt ion exchange liquid with a mass ratio of 0.4:1 to molecular sieves, keep at this temperature for 2 h, and then at 70 o C aged for 36 h, filtered and washed with deionized water, at 90 o C dried overnight. Mix the product and deionized water evenly at a mass ratio of 1:15, and raise the temperature to 150 o C, and at this temperature, slowly add manganese ion exchange liquid with a mass ratio of 1:1 to the product for ion exchange for 2 h, and then at 70 oC Aged for 36 h, filtered and washed with deionized water, at 90 o C dried overnight. The product was placed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com