An intermediate layer assembly and method for connecting Si3N4 ceramics

An intermediate layer and ceramic technology, applied in welding medium, welding equipment, workpiece edge and other directions, can solve the problems of poor performance of brazing joints and high brittleness of brazing filler metals, and achieve the advantages of less impurity content, uniform melting, and improved joint strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

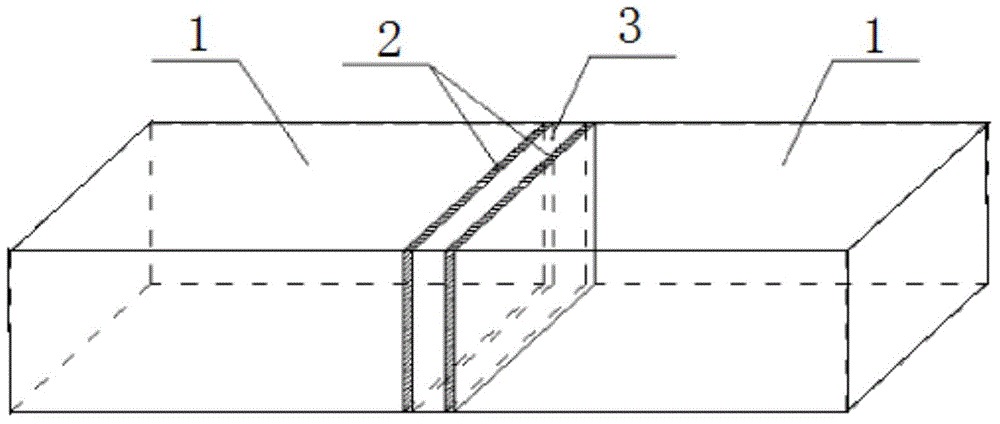

[0032] combine figure 1 , a connection Si of this embodiment 3 N 4 Ceramic intermediate layer assembly, including copper-based amorphous solder foil 2 and intermediate layer 3, the composition and content (by mass percentage) of copper-based amorphous solder foil 2 are: Ti is 20%-25%, Zr is 14%-16%, Hf 12%-14%, Ta 5%-6%, Mo 1.5%-1.8%, Nb 0.6%-0.8%, V 0.2%-0.4%, the rest is Cu, The sum of the mass percentages of each component is 100%; the middle layer 3 has one layer; the copper-based amorphous solder foil 2 has two layers, according to copper-based amorphous solder foil 2 / intermediate layer 3 / copper-based amorphous solder foil 2 in order to be closely assembled; the middle layer 3 can be Ta foil or Nb foil, wherein Ta foil is an industrial-grade product with a purity of more than 99.8% and a thickness of 0.2mm, and Nb foil is a purity of more than 99.8% and a thickness of 0.2mm industrial-grade product, the middle layer 3 is Ta foil in the present embodiment, and wherein ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com