Laser boring method and device assisted by electric field and magnetic field coupling

An auxiliary laser and magnetic field coupling technology, applied in auxiliary devices, laser welding equipment, auxiliary welding equipment, etc., can solve the problems of low repetition accuracy of impact holes, serious plasma shielding effect, and difficulty in improving hole quality, so as to improve the drilling efficiency. Repeatability Accuracy, Increased Material Removal Rate, Reduced Orifice Pressure Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The details and working conditions of the method and device proposed by the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

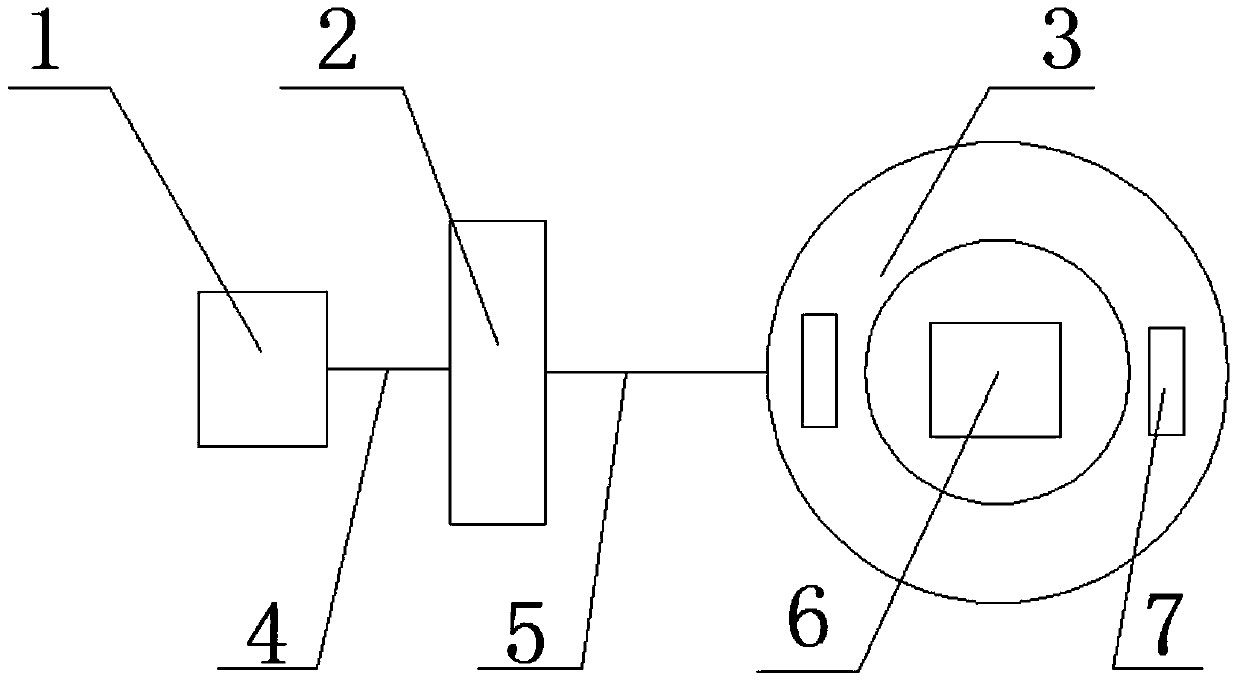

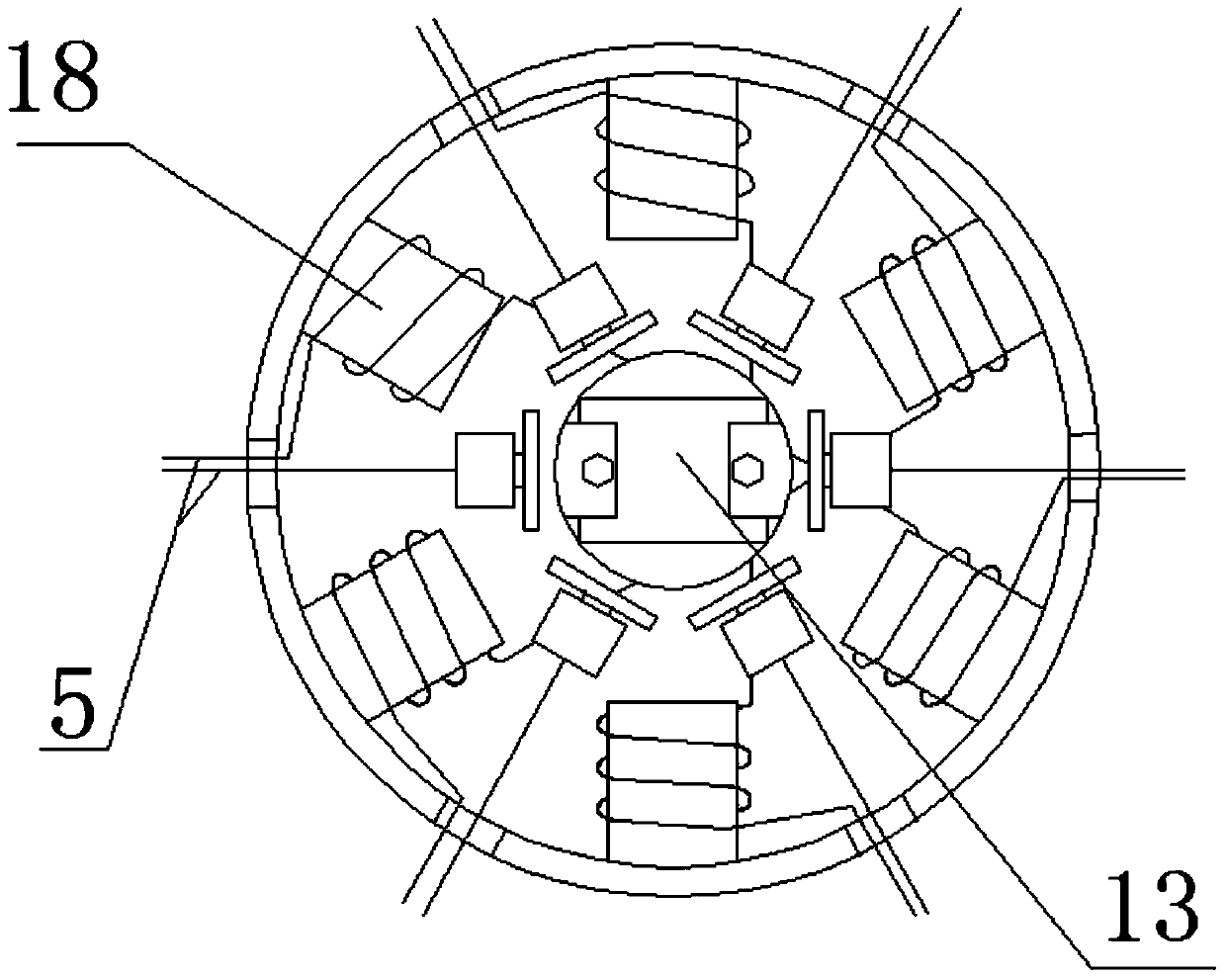

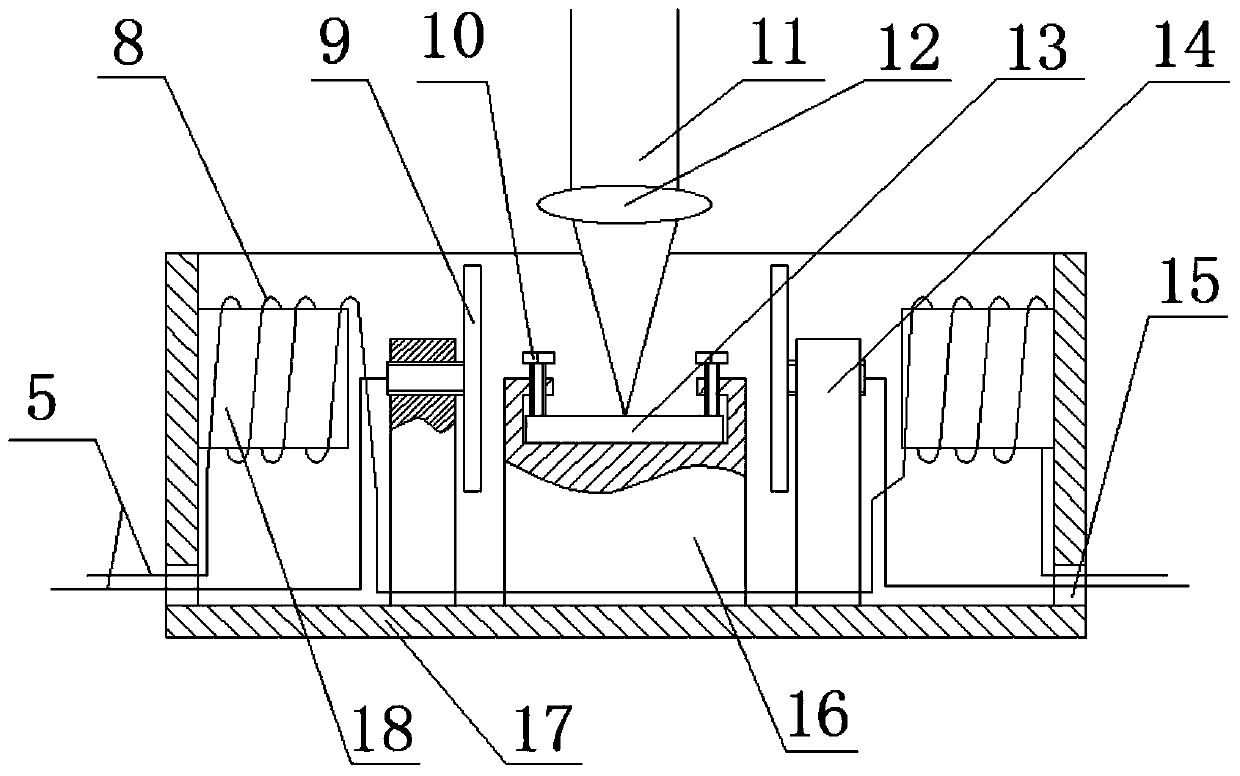

[0037] like Figure 1-3 As shown, the electric field magnetic field coupling assisted laser drilling device provided by the present invention includes a power supply 1, a control circuit 2, a rotating magnetic field generating unit 3, a workpiece clamping unit 6 and an electric field generating unit 7, wherein the power supply 1 communicates with the control unit through a cable 4 The circuit 2 is connected, the control circuit 2 is respectively connected to the rotating magnetic field generating unit 3 and the electric field generating unit 7 through the wire 5, and the workpiece clamping unit 6 is fixed at the horizontal center ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com