3D printing technology for ultrasonic shot-peening based on laser welding

An ultrasonic shot peening and 3D printing technology, applied in the field of 3D printing technology, can solve problems such as poor tissue mechanical properties, and achieve the effect of improving microstructure and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

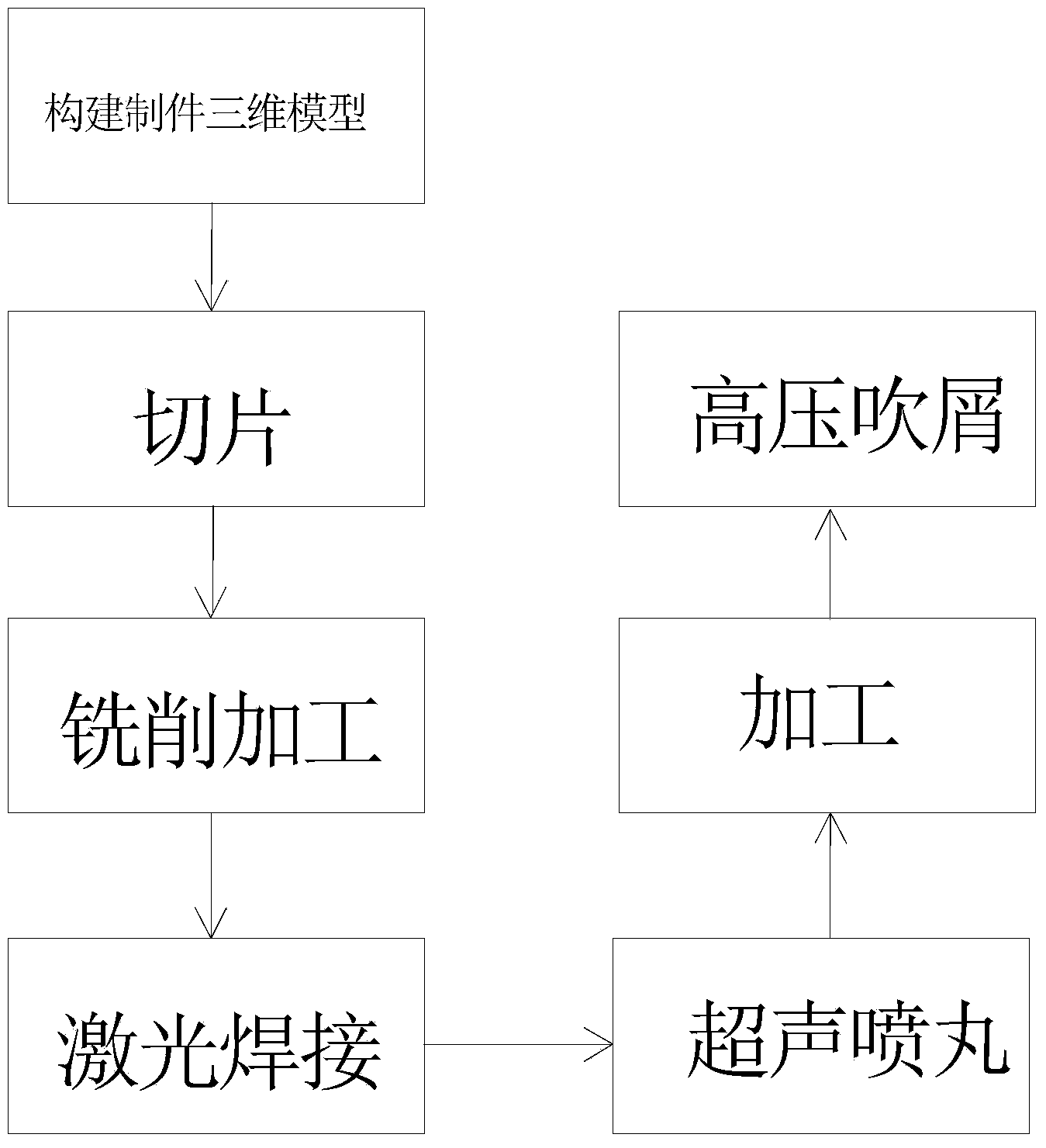

[0009] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0010] As shown in Figure 1, a 3D printing technology based on laser welding and ultrasonic shot peening, first constructs a 3D model of the part in the computer, and then slices the 3D model according to the thickness of the sheet to obtain the sections at various heights of the part Shape, cut the required section from the sheet by milling, place the sheet with suitable width on the liftable workbench and fix it, scan the section of the part with the laser beam along a certain track, and make the sheet The section area above is completely welded with the previously processed section. While the laser beam is scanning and moving, the tool head of the ultrasoni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com