Method for preparing hydrogen fluoride by using phosphorus fertilizer by-product fluosilicic acid

A fluorosilicic acid and by-product technology, applied in fluorine/hydrogen fluoride, silicon oxide, etc., can solve the problems of fluorine pollution, waste of fluorite resources, etc., and achieve the effect of increasing investment, good economic benefits, and increasing the added value of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

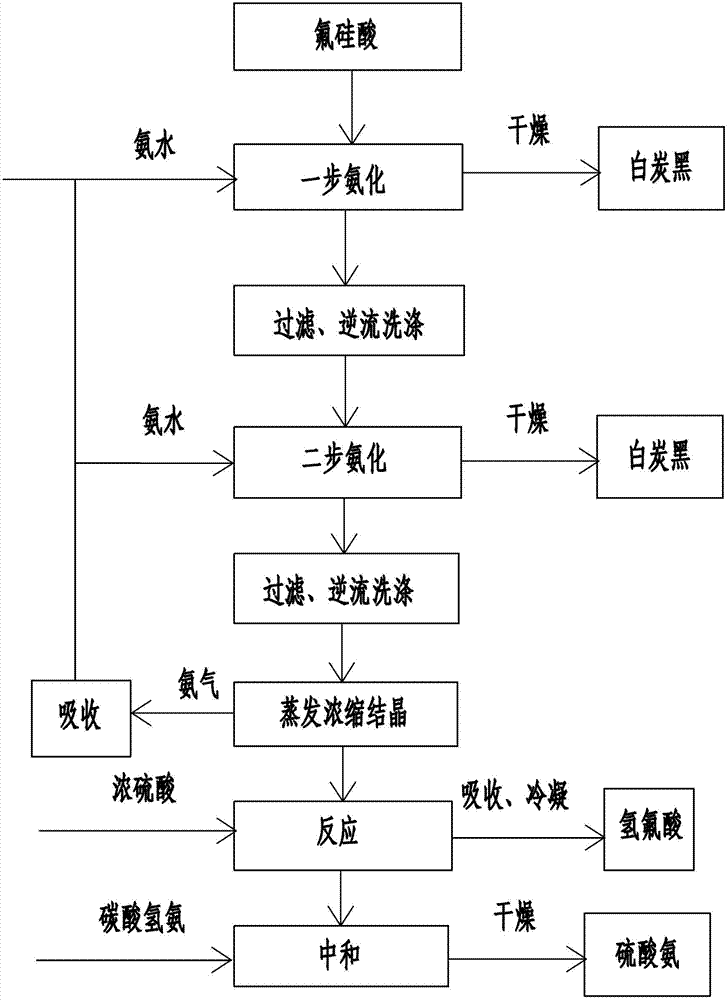

Image

Examples

Embodiment 1

[0023] Add 260g, 14% fluosilicic acid solution to the reactor with stirrer, the temperature is 20-25°C, then slowly drop 55g, 31% concentrated ammonia water into the fluosilicic acid solution, after the reaction is completed, The temperature is 55-60°C, aged for 40 minutes, and then the first step of filtration is carried out. The filter cake obtained by filtration is washed several times to recover the fluorine mother liquor, and 33g of 31% concentrated ammonia water is slowly dripped into the filtrate obtained by the first step of filtration. After the reaction is completed, the temperature is 50-56 ° C, aged for 40 minutes, and then the second step of filtration is carried out, and the filtered cake is washed several times to recover the fluorine mother liquor; the solution obtained in the second step is evaporated, concentrated and crystallized to obtain ammonia hydrogen fluoride Solid and ammonia gas, the collected ammonia gas can be made into ammonia water, which can be d...

Embodiment 2

[0031] Operation is with embodiment 1. Add 175g, 20% fluosilicic acid solution to the reactor with stirrer, the temperature is 20-25°C, then slowly drop 48g, 35% concentrated ammonia water into the fluosilicic acid solution, after the reaction is completed, The temperature is 71-76°C, aged for 40 minutes, and then the first step of filtration is carried out. The filter cake obtained by filtration is washed several times to recover the fluorine mother liquor, and 28g of 35% concentrated ammonia water is slowly added to the filtrate obtained by the first step of filtration. After the reaction is completed, the temperature is 65-70°C, aged for 40 minutes, and then the second step of filtration is carried out, and the filtered cake is washed several times to recover the fluorine mother liquor; Ammonia gas, the collected ammonia gas can be directly used in the subsequent ammoniation reaction to make ammonia water; the ammonia hydrogen fluoride obtained in the third step is dissolve...

Embodiment 3

[0033] Operation is with embodiment 1. Add 175g, 20% fluosilicic acid solution to the reactor with stirrer, the temperature is 20-25°C, then slowly drop 42g, 40% concentrated ammonia water into the fluosilicic acid solution, after the reaction is completed, The temperature is 87-92°C, age for 40 minutes, and then perform the first step of filtration. The filter cake obtained by filtration is washed several times to recover the fluorine mother liquor, and slowly drop 24.5g of 40% concentrated ammonia water into the filtrate obtained by the first step of filtration. , after the reaction is completed, the temperature is 81-86 ° C, aged for 40 minutes, and then the second step of filtration is carried out, and the filtered cake is washed several times to recover the fluorine mother liquor; the solution obtained in the second step is evaporated, concentrated and crystallized, and ammonia hydrogen fluoride is solid and ammonia gas, the collected ammonia gas can be made into ammonia ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com