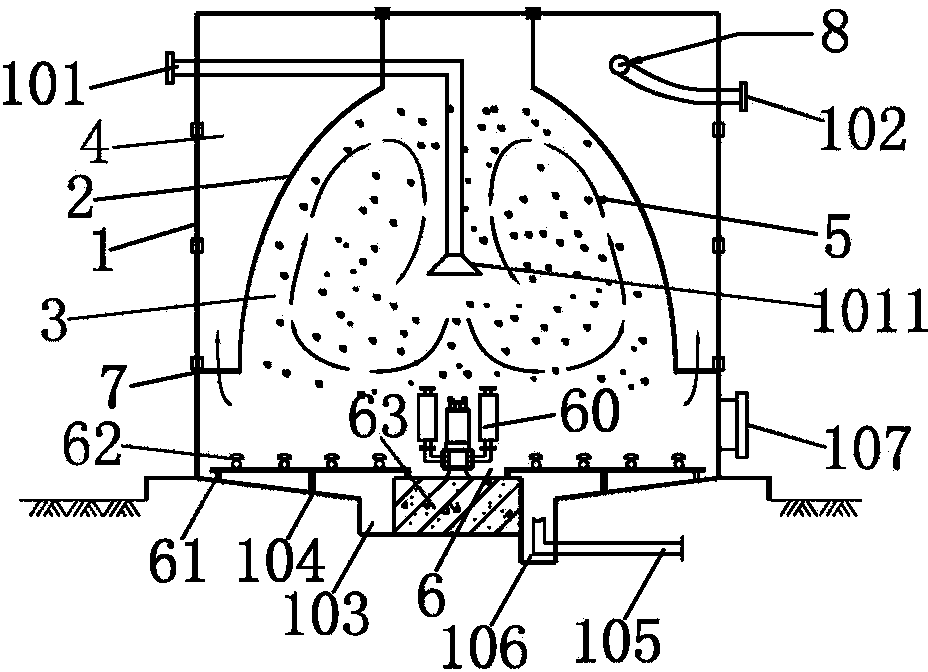

Assembled sequencing batch fluidized bed sewage treatment equipment and process

A technology of sewage treatment equipment and batch fluidized bed, which is applied in the field of assembled sequence batch fluidized bed sewage treatment equipment and technology, and can solve the problems of complex construction process of reinforced concrete pools, limited application of bioreactors, difficulty in guaranteeing construction quality, etc. , to achieve the effect of improving mass transfer efficiency and utilization, saving energy consumption, and easy to control the installation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

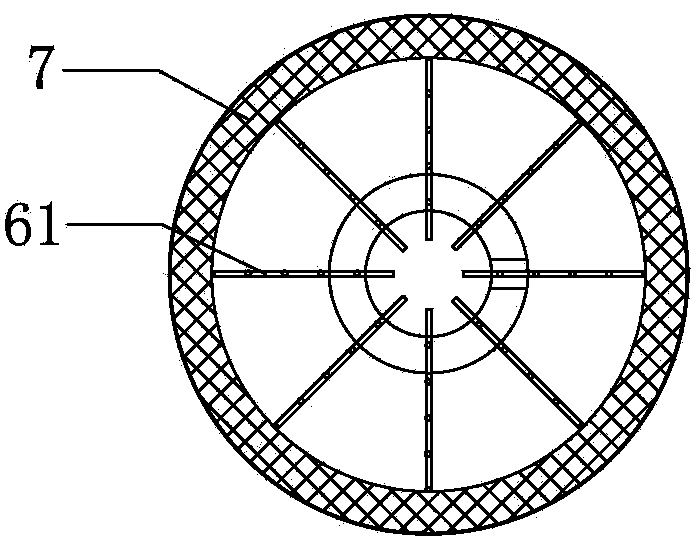

Method used

Image

Examples

Embodiment

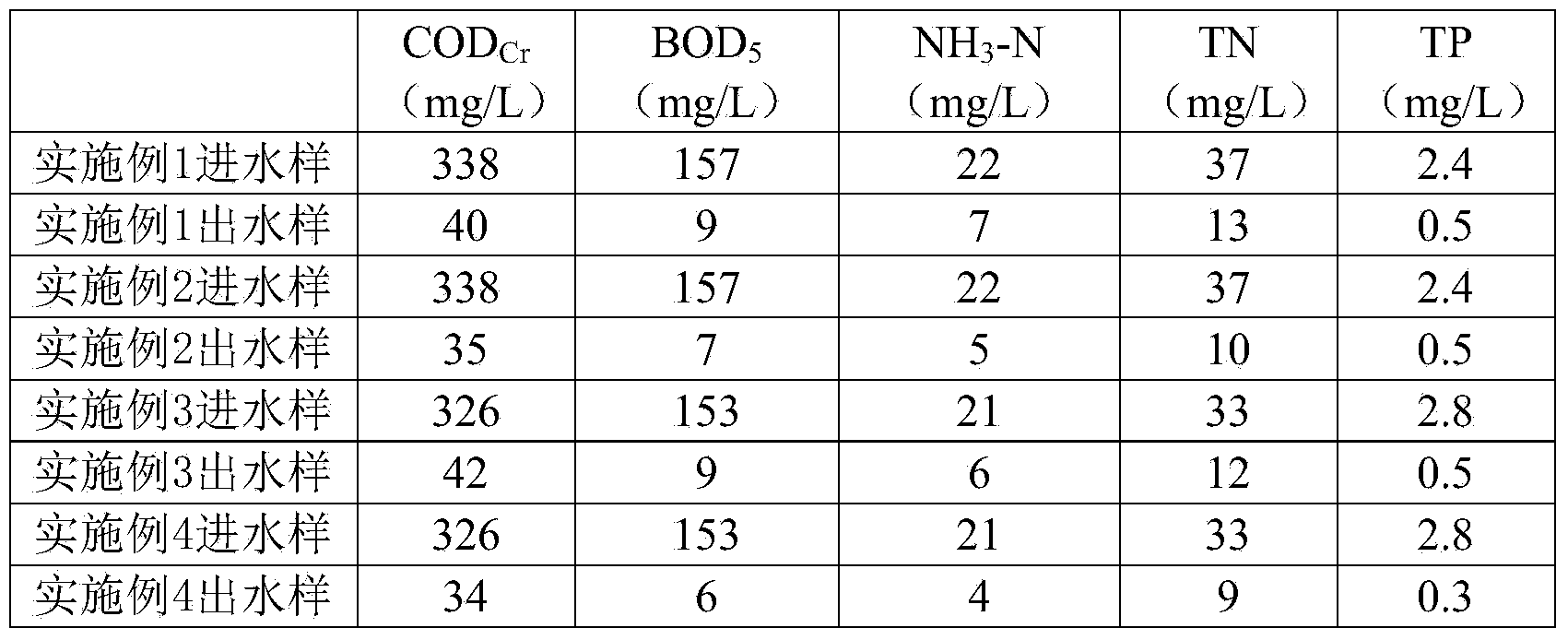

[0037] Taking the sewage treatment of a city as an example, the sewage treatment equipment and process of the sequence batch fluidized bed of the present invention are used for treatment. Under normal operation conditions, the water quality of the influent and effluent of the two samplings is shown in the table below; wherein Example 1 and Example 2 1, Example 3 and Example 4 have the same inlet water samples, the difference is that Example 1 and Example 3 use common suspension fillers, and Embodiment 2 and Example 4 use preferred suspension fillers of the present invention.

[0038]

[0039] It can be seen from the above table that, whether the equipment and process are used for sewage treatment, no matter the ordinary suspended filler or the suspended filler disclosed by the present invention is used, the quality of the effluent can fully meet the "Pollutant Discharge Standards for Urban Sewage Treatment Plants" GB18918-2002 The first-level A standard, and the suspension f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com