Method for separating ethyl acetate-isopropanol by ionic liquid extractive rectification

A technology of ethyl acetate and ionic liquids, applied in extraction distillation, preparation of carboxylic acid esters, chemical instruments and methods, etc., can solve the problems of high energy consumption and large consumption, and achieve good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

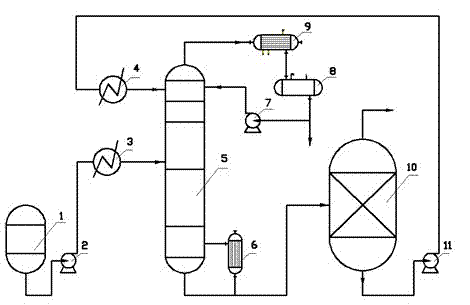

[0017] Embodiment 1: as figure 1 The extractive distillation process shown. The extractive distillation column has 20 trays, and the ionic liquid extractant enters from the third tray after being heated, with a flow rate of 90kg / h, and the mixture of ethyl acetate and isopropanol is added from the tenth tray of the tower to form ethyl acetate 45wt% , isopropanol 55 wt%, the flow rate is 90kg / h, the extractive distillation column is operated at normal pressure, the reflux ratio is 2, the output of the tower top product is 40.5kg / h, the temperature of the extractive distillation column top is 77.1°C, and the temperature of the bottom of the tower is It is 90.8 ℃, and as a result, an ethyl acetate product with a mass fraction of 99.0% can be obtained at the top of the tower.

[0018] The mixture of isopropanol and ionic liquid from the bottom product of the extractive distillation tower enters the solvent recovery flash tank, and the flash temperature is 90°C. The isopropanol pr...

Embodiment 2

[0019] Embodiment 2: as figure 1 The extractive distillation process shown. The extractive distillation column has 25 trays, and the ionic liquid extractant enters from the fifth tray after being heated, with a flow rate of 110kg / h, and the mixture of ethyl acetate and isopropanol is added from the 15th tray of the tower to form ethyl acetate 55wt% , isopropanol 45 wt%, the flow rate is 90kg / h, the extractive distillation column is operated at normal pressure, the reflux ratio is 3, the output of the tower top product is 49.5kg / h, the temperature of the extractive distillation column top is 77.1°C, and the temperature of the bottom of the tower is It is 100°C, and as a result, an ethyl acetate product with a mass fraction of 99.5% can be obtained at the top of the tower.

[0020] The mixture of isopropanol and ionic liquid in the bottom product of the extraction and rectification column enters the solvent recovery flash tank, and the flash temperature is 120°C. The isopropano...

Embodiment 3

[0021] Embodiment 3: as figure 1 The extractive distillation process shown. The extractive distillation column has 30 trays, and the ionic liquid extractant enters from the seventh tray through heating, with a flow rate of 130kg / h, and the mixture of ethyl acetate and isopropanol is added from the tenth tray of the tower to form ethyl acetate 75wt% , isopropanol 25 wt%, the flow rate is 90kg / h, the extractive distillation column is operated at normal pressure, the reflux ratio is 2, the output of the tower top product is 67.5kg / h, the temperature of the extractive distillation column top is 77.1°C, and the temperature of the bottom of the tower is It is 121 ℃, and as a result, the ethyl acetate product with a mass fraction of 99.9% can be obtained at the top of the tower.

[0022] The mixture of isopropanol and ionic liquid at the bottom of the extraction and rectification column enters the solvent recovery flash tank, and the flash temperature is 110°C. The isopropanol produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com