Preparation method of high-purity 11S glycinin and application thereof

A technology of soybean globin and protein, which is applied in the direction of chemical instruments and methods, plant peptides, peptide sources, etc., can solve the problems of complicated and lengthy separation process, limit the application of two kinds of proteins, and low protein purity, and achieve simple process and easy assembly line Separation and purification, the effect of improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、11

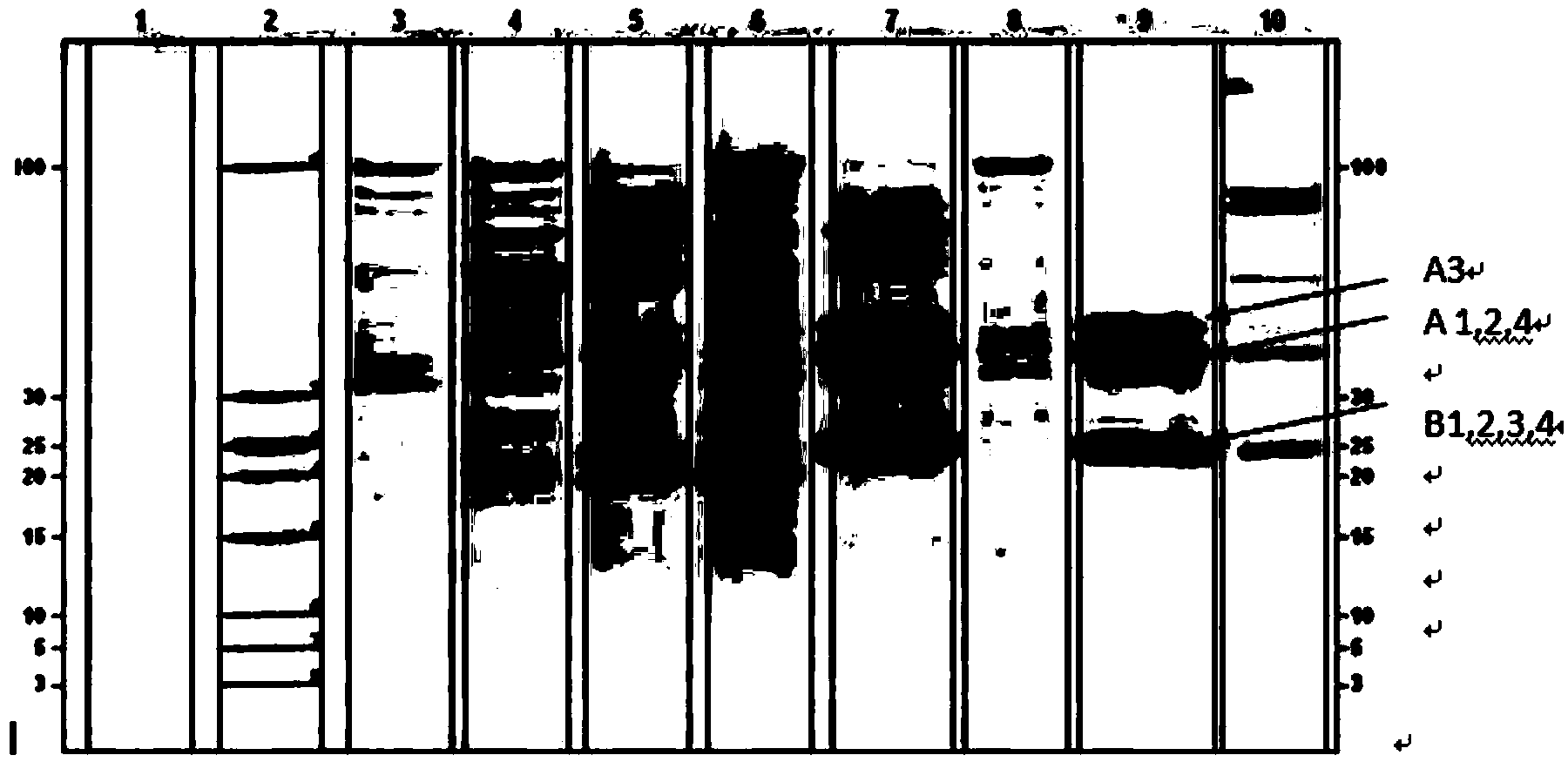

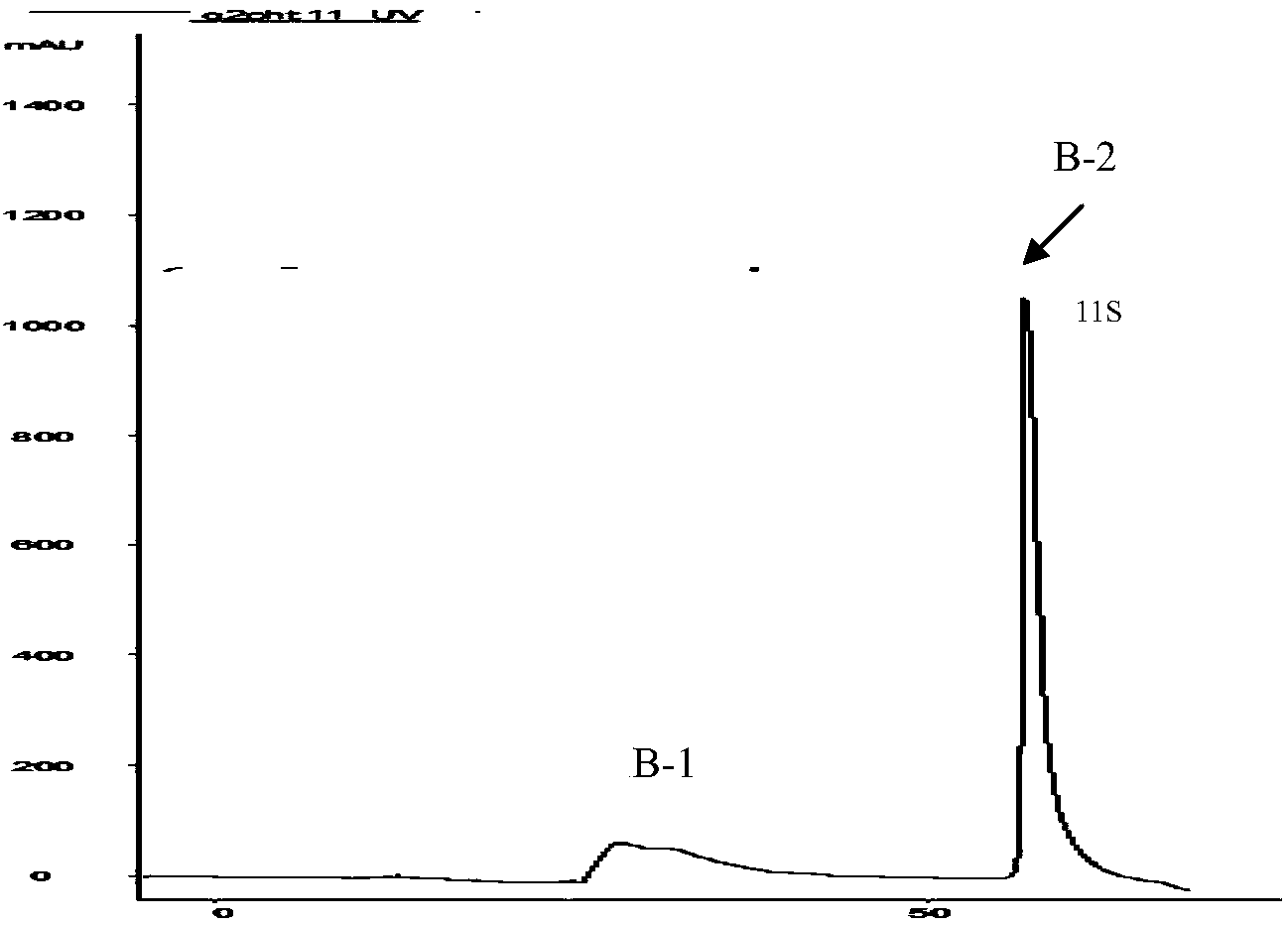

[0055] The separation and purification of embodiment 1, 11S glycinin

[0056] 1. Crude Extraction of 11S Glycinin

[0057] (1) Mix defatted soybean powder with 50mM Tris-HCl buffer (containing 10mM mercaptoethanol) at a volume ratio of 1g:20ml, extract at 37°C for 1 hour, centrifuge at 10,000rpm at 28°C for 15 minutes, and collect the supernatant .

[0058] (2) Adjust the pH of the supernatant to 6.4 with 2 mol / L HCl, centrifuge at 10,000 rpm for 15 minutes at 28°C, and collect the precipitate.

[0059] (3) Dissolve the precipitate with 50 mM Tris-HCl buffer solution with pH 8.0, and collect the filtrate by filtering through a 0.45 μm filter membrane.

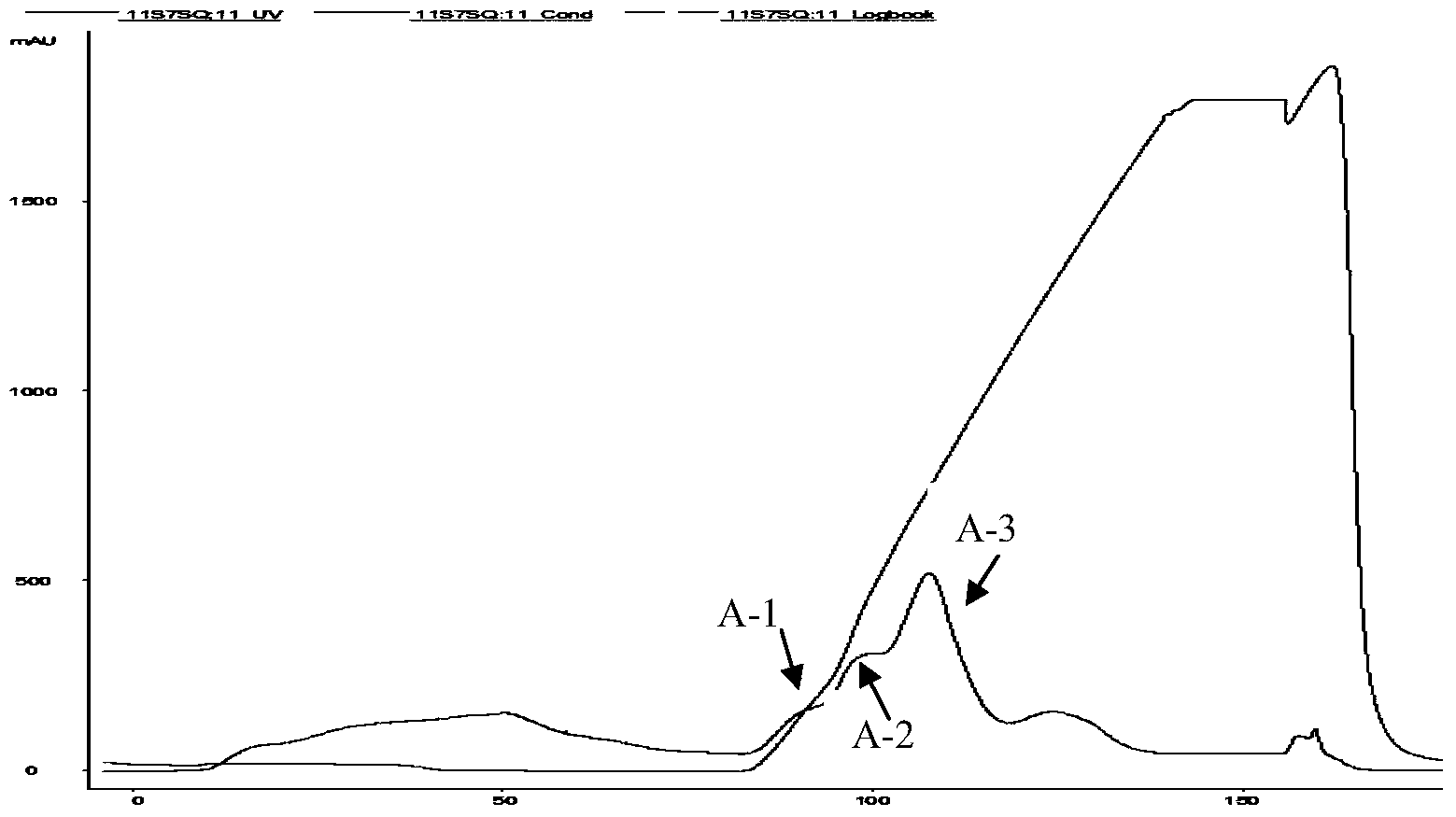

[0060] 2. Strong anion exchange chromatography of 11S glycinin

[0061] (1) Take 10ml of Capto Q filler and fill it into an XK16 / 20 column (inner diameter 1.6cm, filler height 5cm). After filling, equilibrate 10 column volumes with 50mM Tris-HCl buffer, pH 8.0.

[0062] (2) Put the filtrate obtained in step 1 on the column,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sedimentation rate | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| sedimentation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com