Environment-friendly coating with visible light catalysis function, and preparation method thereof

An environmentally friendly coating and visible light technology, applied in radiation-absorbing coatings, powder coatings, alkali metal silicate coatings, etc., can solve the problems of easy loss of doping elements, weak light absorption ability, loss of catalytic activity, etc., to avoid acceleration Effect of aging and destroying resin, low cost, degrading harmful substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

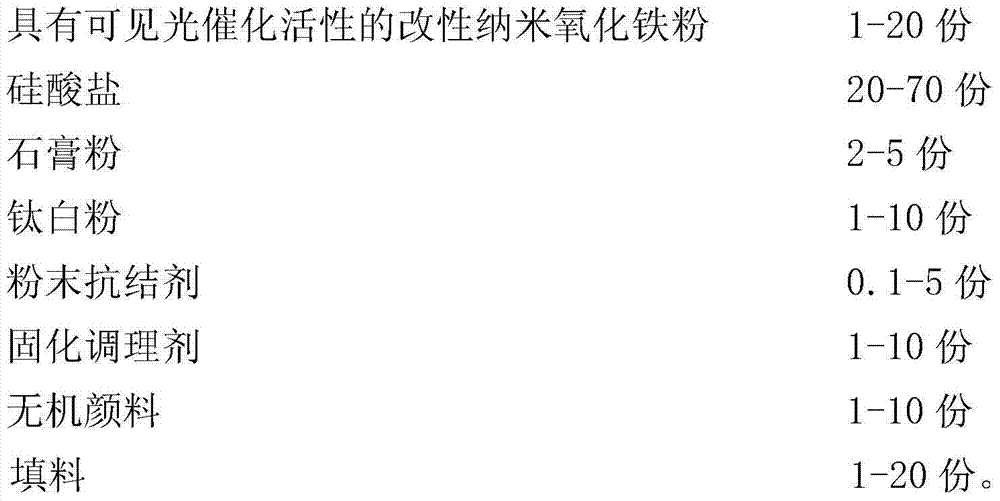

[0037] A kind of environment-friendly paint with visible light catalytic function is prepared by following raw materials according to the following weight ratio:

[0038]

[0039]

[0040] The preparation method of the environmentally friendly coating with visible light catalytic function is as follows:

[0041] Add each raw material in the ball mill, and grind for 6 hours at a speed of 1500 rpm;

[0042] After the coating is ground, it is filtered with a 400-mesh filter and filled with nitrogen at a pressure of 0.10 MPa for packaging.

Embodiment 2

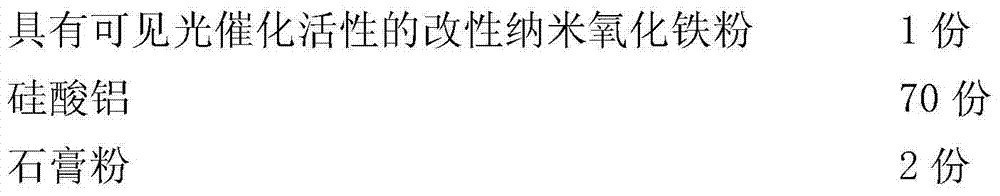

[0044] A kind of environment-friendly paint with visible light catalytic function is prepared by following raw materials according to the following weight ratio:

[0045]

[0046] The preparation method of the environmentally friendly coating with visible light catalytic function is as follows:

[0047] Put each raw material in the ball mill and grind for 0.5 hour at a speed of 700 rpm;

[0048] After the paint is ground, filter it with a 300-mesh filter, and fill it with nitrogen with a pressure of 0.13Mpa for packaging.

Embodiment 3

[0050] A kind of environment-friendly paint with visible light catalytic function is prepared by following raw materials according to the following weight ratio:

[0051]

[0052]

[0053] The preparation method of the environmentally friendly coating with visible light catalytic function is as follows:

[0054] Put each raw material into a ball mill and grind for 3 hours at a speed of 1100 rpm.

[0055] After the coating is ground, filter it with a 350-mesh filter, and fill it with nitrogen at a pressure of 0.12MPa for packaging.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com