Binding material of anti-skidding layer of road surface and preparation method

A technology of bonding materials and thin layers, applied in the directions of roads, roads, adhesives, etc., can solve the problems of brittle cracking, stone falling off, poor bonding, etc., and achieve the effects of simple production process, increased friction, and improved roughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

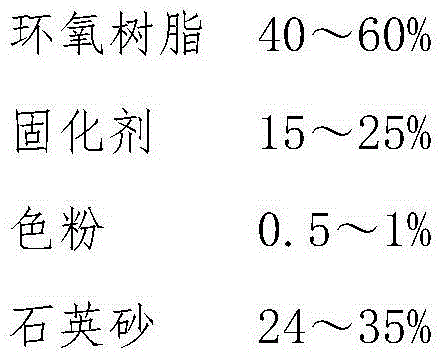

[0029] The epoxy resin formulation is shown in Table 1.

[0030] Table 1 Epoxy Resin Recipe

[0031]

[0032] Preparation Process:

[0033] Add acrylic epoxy resin, polyurethane epoxy resin and rubber epoxy resin in weight percentage to the reaction pot, raise the temperature to 70°C, control the temperature to 70°C±5°C, stir and react, after the reaction is complete, cool the reaction pot materials to 50°C, high-speed dispersion for 0.5h to obtain epoxy resin.

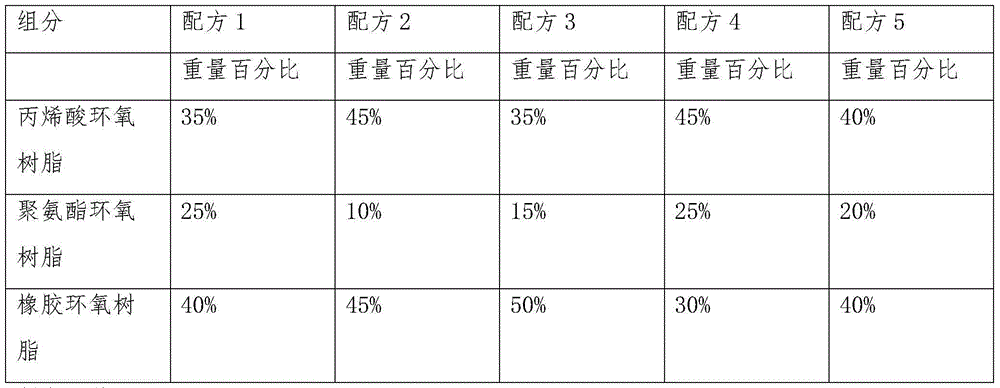

[0034] Examples 2-6 bonding materials, the formulations are shown in Table 2.

[0035] Table 2 embodiment 2~6 the component charging percentage of bonding material

[0036]

[0037] Preparation Process:

[0038] Mix and stir the epoxy resin prepared in Example 1 with curing agent, toner and quartz sand for 3-4 minutes to prepare the anti-skid thin-layer adhesive material for road surface.

Embodiment 7

[0039] The construction steps of embodiment 7 pavement antiskid thin layer:

[0040] 1) Clean the cement pavement or steel plate surface, and grind the surface rough,

[0041] 2) Apply the anti-skid thin-layer bonding material for road surface of Examples 2 to 6 on the cement road surface, asphalt road surface or steel plate surface,

[0042] 3) Sprinkle natural special stones or ceramic granules on the surface of the bonding material in step 1) to form a 5mm±1mm colored thin-layer anti-skid road surface.

Embodiment 8

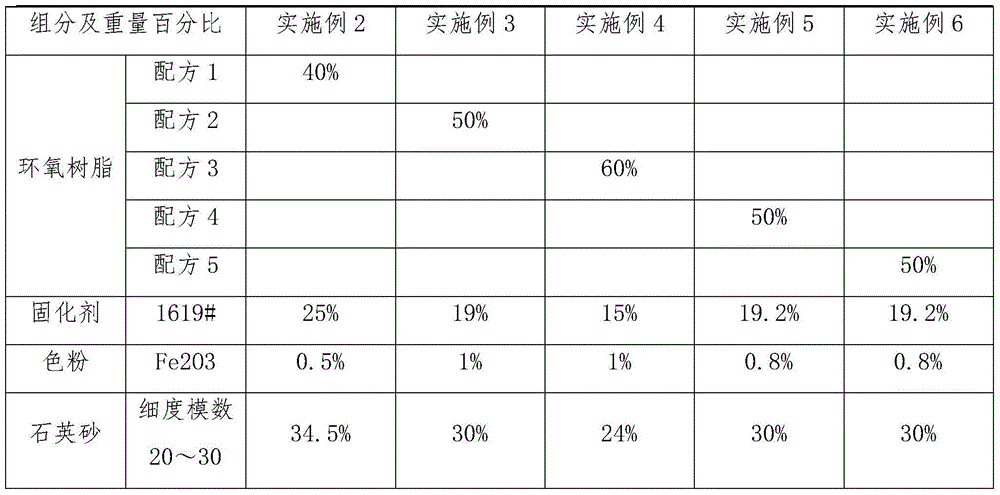

[0043] Embodiment 8 performance test

[0044] Performance index test, except for the method indicated in the table below, the rest are tested according to the method in the traffic industry standard "Pavement Anti-skid Coating" (JT / T712~2008), the test results are shown in Table 3

[0045] Table 3 performance test results

[0046]

[0047] *Chemical corrosion resistance: After making the anti-slip thin layer with the adhesive materials of Examples 2-6, soak the thin layer with gasoline, kerosene, strong acid, strong alkali, xylene, etc. for 24 hours, and observe that there is a change.

[0048] **Low temperature crack resistance: After the adhesive materials of Examples 2-6 are made into anti-skid thin layers, the thin layers are kept in an environment of -10°C for 4 hours, and then stored at room temperature for 4 hours. After one cycle and three consecutive cycles, observe whether there are cracks, etc.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com