Application of hydrogen inhibitor in self-heating food heating agent

A technology of heating agent and hydrogen suppressing agent, which is applied in the application field of hydrogen suppressing agent in self-heating food heating agent, can solve the problems of slow speed, difficult to realize, insufficient to completely remove hydrogen, etc., and achieve the effect of suppressing hydrogen generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

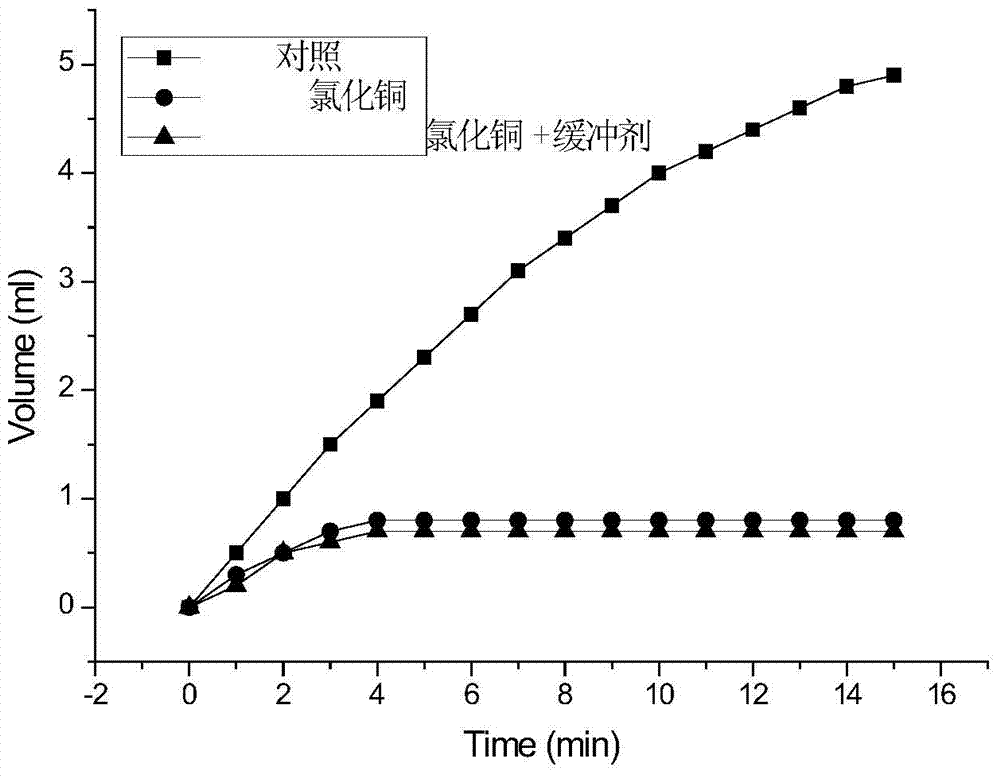

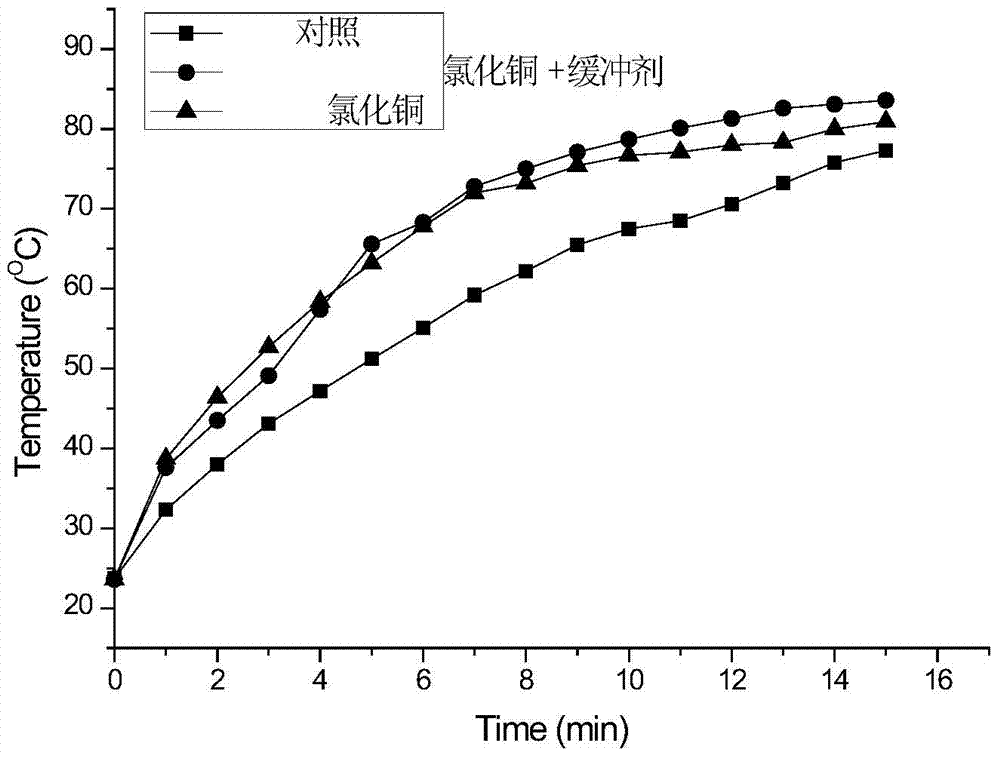

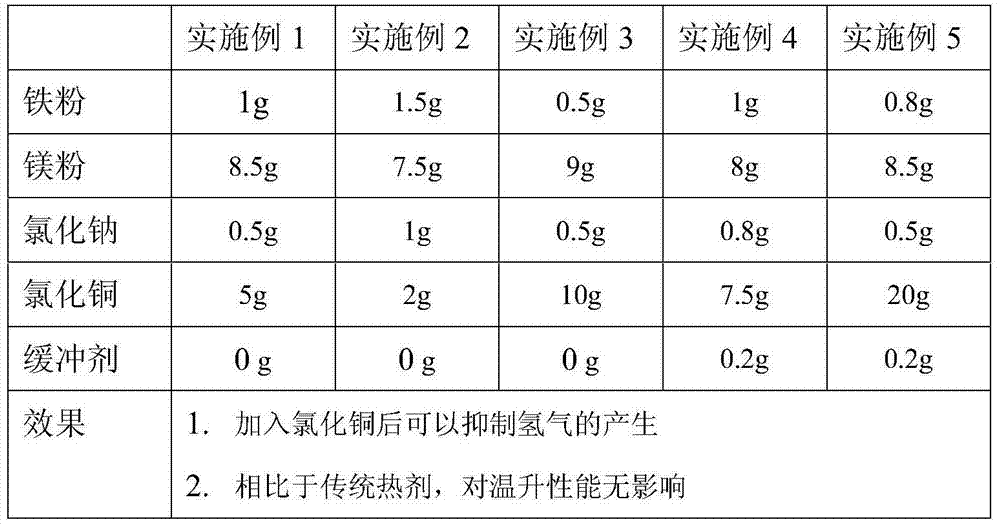

[0019] Adopt mechanical ball milling method to make 9.5g of magnesium-iron alloy particle after 1g iron powder, 8.5g magnesium powder ball mill, then add 0.5g sodium chloride and mix after uniformly obtain heating agent, add 5g anhydrous cupric chloride in heating agent, Mix the heating agent and anhydrous copper chloride evenly, and pack them in 10×15 quadruple-packed polyester non-woven fabrics, put 3.75g in each small chamber of the non-woven bag, put the heating agent bag into the heating The bag is used to heat a 240g water bag, add 30ml of water to the heating bag to initiate the reaction, collect the generated gas by drainage method, and record the temperature value. Simultaneously, carry out the experiment of the control group, the control group 1 is magnesium-iron alloy particle 9.5g, 1.5g sodium chloride, is packed in the polyester non-woven fabric of 10 * 15 quadruple packs, in each small chamber of the non-woven bag Load 2.75g of thermal agent components, put the t...

Embodiment 2

[0021] Adopt mechanical ball milling method with 1.5g iron powder, after 7.5g magnesium powder ball milling, make magnesium-iron alloy particle 9g, then add 1g sodium chloride and mix uniformly to obtain heating agent, add 2g anhydrous cupric chloride in heating agent, will The heating agent is evenly mixed with anhydrous copper chloride, and packed in 10×15 quadruple-packed polyester non-woven fabrics, and 3g is put into each small chamber of the non-woven bag, and the heating agent pack is put into the heating bag It is used to heat a 240g water bag, add 30ml water to the heating bag to initiate the reaction, collect the generated gas by drainage method, and record the temperature value. At the same time, carry out the experiment of the control group, the control group 2 is 9g of magnesium-iron alloy particles, 1.5g of sodium chloride, which are packed in 10×15 quadruple-packed polyester non-woven fabrics, and each small chamber of the non-woven bag contains Add 2.625g of th...

Embodiment 3

[0023] Adopt mechanical ball milling method to make 9.5g of magnesium-iron alloy particle after 0.5g iron powder, 9g magnesium powder ball mill, then add 0.5g sodium chloride and mix evenly to obtain heating agent, add 10g anhydrous cupric chloride in heating agent, Mix the heating agent and anhydrous copper chloride evenly, and pack them in 10×15 quadruple-packed polyester non-woven fabrics, put 5g in each small chamber of the non-woven bag, and put the heating agent pack into the heating bag It is used to heat a 240g water bag, add 30ml water to the heating bag to initiate the reaction, collect the generated gas by drainage method, and record the temperature value. At the same time, carry out the experiment of the control group, the control group 3 is 9.5g of magnesium-iron alloy particles, 1.5g of sodium chloride, which are packed in 10×15 quadruple-packed polyester non-woven fabrics, and each small chamber of the non-woven fabric bag Load 2.75g of thermal agent components,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com