Coated paper suitable for high-speed ink-jet printer and production method thereof

An inkjet printing press, coated paper technology, applied in papermaking, surface covering paper, textiles and papermaking, etc., can solve the problems of inability to produce printed matter, weak adhesion of printed images, poor ink absorption performance, etc. Anti-scratch requirements, excellent anti-scratch performance, high-definition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

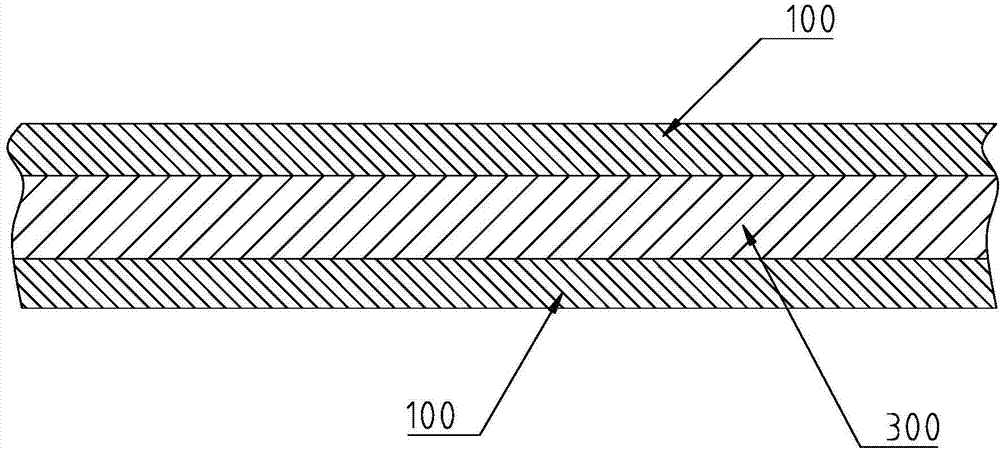

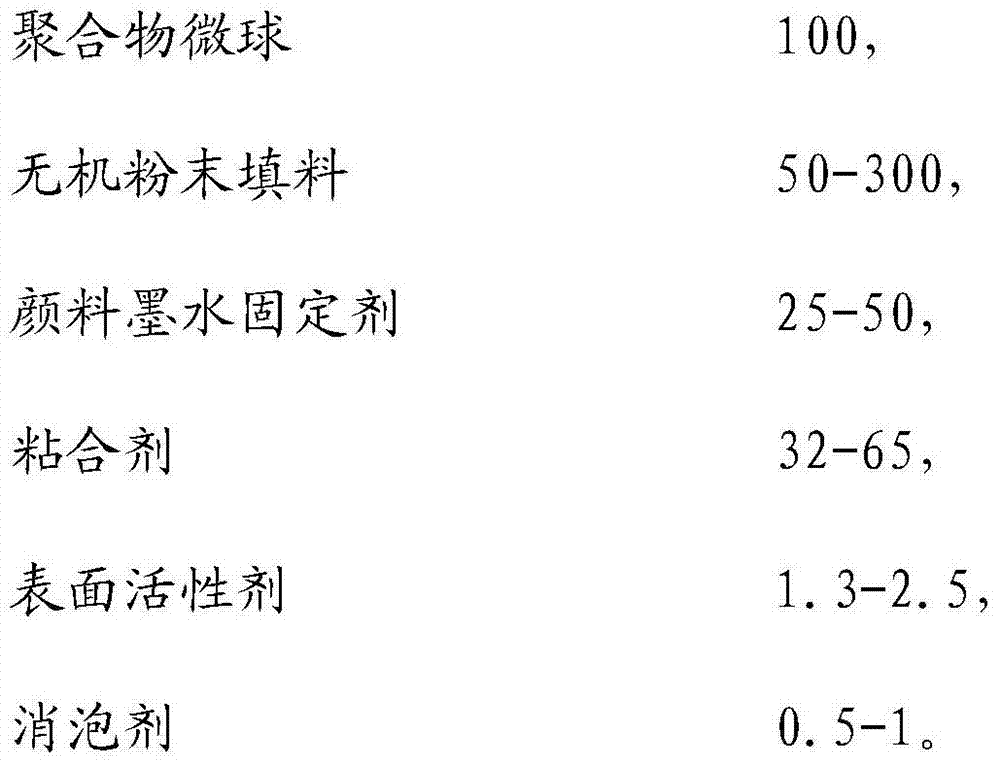

[0050] Embodiment 1-6: Preparation of the coating liquid of the ink absorbing coating 100

[0051]Table 1 lists some formulation examples 1-6 of the ink-absorbing coating, and the listed fractions are parts by weight of each component. Among them, DS-PP801 (Shandong Jining Dongsheng Xu Company) is an emulsion of polymer microspheres, the weight percentage of polymer microspheres in the emulsion is 50%, the average particle size of polymer microspheres is 0.5 microns, and the glass transition temperature is 100 degrees Celsius . Matting powder and ultrafine SiO2 (Guangzhou Zhangqi Environmental Protection Technology Co., Ltd.) are inorganic powder fillers of silica; DS-GCC95 (Shandong Jining Dongsheng Xu Company) are inorganic fillers of calcium carbonate; calcined kaolin (Datong Coal Industry Jinyu Kaolin Chemical II Co., Ltd.) is an inorganic filler for kaolin. The pigment ink fixative is CaCl2, the binder includes DS-SA823 (Shandong Jining Dongsheng Xu Company) and PVA 179...

Embodiment 7-8

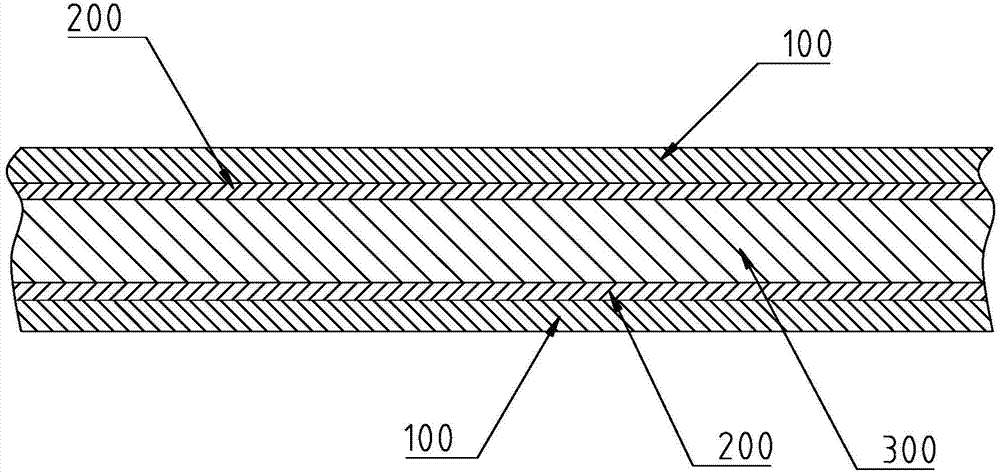

[0055] Embodiment 7-8: the preparation of the coating liquid of precoat 200

[0056] Table 2 lists some formulation examples 7-8 of the precoat, wherein the listed fractions are parts by weight of each component. Ultrafine SiO2 (Guangzhou Zhangqi Environmental Protection Technology Co., Ltd.) is an inorganic powder filler of silica; DS-GCC95 (Shandong Jining Dongsheng Xu Company) is an inorganic filler of calcium carbonate; calcined kaolin (Datong Coal Jinyu Kaolin Chemical Co., Ltd. company) is an inorganic filler for kaolin. Adhesives include DS-SA823 (Shandong Jining Dongsheng Asahi Co., Ltd.) and PVA 1799 (Nippon Synthetic Chemicals), the surfactant is TegoWet 500 (Evonik), and the defoamer is Tego 825 (Evonik). The preparation methods of the two enumerated coating solutions are as follows: each component is weighed according to the parts in the table and mixed in a 500 ml beaker, stirred with a mechanical stirrer for one hour, and left to stand for use.

[0057] Table 2...

Embodiment 9-16

[0059] Embodiment 9-16: Preparation of coated paper and its performance test

[0060] Table 3 lists the preparation methods of some coated paper samples, which respectively list the formulations of the ink-absorbing coatings used and their coating weights. Examples 15-16 also include the formulations of the pre-coatings used and their coating weights. . All coated paper samples use 70gsm office A4 paper (Yalong paper products) as the substrate, use a suitable coating bar to obtain the desired coating weight, and then dry naturally at room temperature for 20 minutes, and then use a hair dryer with hot air dry. The dried sample is laminated by a laboratory calender (PL23 experimental calender, Xianyang Taisite Experimental Equipment Co., Ltd.), the lamination conditions are calendering temperature 100 degrees Celsius, pressure 15N / mm, lamination The number of times is one time.

[0061] Table 3. Examples 9-16 of coated paper samples:

[0062]

[0063] All coated paper sam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com